cable flexibility test machine factory

The Importance of Cable Flexibility Test Machines in Modern Manufacturing

In the rapidly advancing world of technology, the integrity and reliability of cables are paramount. Cables are integral components in various electrical and electronic applications, from everyday household appliances to advanced industrial machinery. With increasing reliance on these components, ensuring their quality becomes crucial. One of the critical tests conducted during cable manufacturing is the cable flexibility test, which is essential in assessing a cable's durability and performance under various conditions.

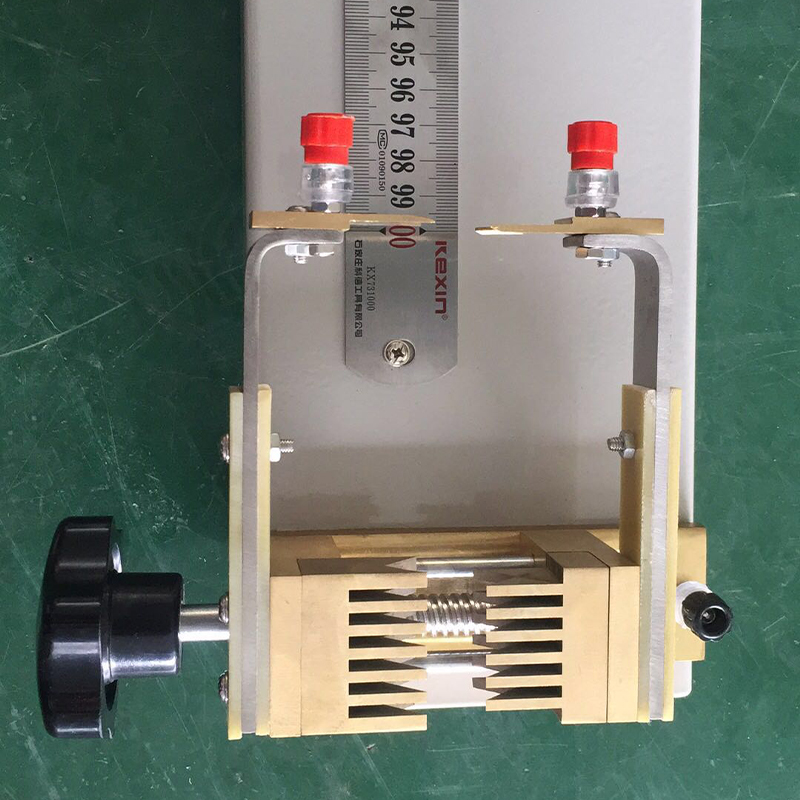

A cable flexibility test machine is a specialized piece of equipment designed to simulate the bending and flexing of cables in real-world applications. This machine evaluates how well a cable can withstand repeated flexing without suffering damage or loss of functionality. The test typically involves subjecting the cable to a series of bending cycles at specified angles and radii, replicating the conditions the cable will face in actual usage.

Manufacturers invest in high-quality cable flexibility test machines for several reasons. Firstly, these machines help to ensure compliance with industry standards and regulations. For cables to be sold in various markets, they must meet specific safety and performance criteria. By conducting flexibility tests, manufacturers can produce cables that adhere to these standards, ensuring consumer safety and product reliability.

cable flexibility test machine factory

Moreover, cable flexibility test machines contribute to quality control throughout the manufacturing process. By regularly testing samples of the cables produced, manufacturers can identify potential weaknesses or defects early on. This proactive approach not only helps in minimizing waste and reducing costs associated with faulty products but also enhances the overall quality of the final output.

Another significant aspect of cable flexibility testing is its role in product development and innovation. The insights gained from these tests allow engineers to fine-tune cable designs and materials, leading to improved performance characteristics. For instance, by understanding how different materials react to flexing, manufacturers can develop cables that are more durable, flexible, and resistant to environmental factors such as temperature and humidity. This continual improvement process is critical in a competitive marketplace where performance and reliability are key differentiators.

Furthermore, cable flexibility test machines are designed with advanced technology, enabling high precision and accuracy in testing. Modern machines often come equipped with automated features and real-time data analysis capabilities. This not only enhances efficiency but also provides manufacturers with detailed reports on the performance of their cables. Such technology enables quick adjustments and optimizations in the manufacturing process, significantly reducing the time-to-market for new products.

In conclusion, cable flexibility test machines play a vital role in the manufacturing of cables, ensuring safety, quality, and innovation. As technology continues to evolve, the demand for reliable and durable cables will only increase, making these testing machines indispensable in modern production environments. Investing in advanced cable flexibility test machines not only helps manufacturers meet regulatory requirements but also positions them as leaders in quality and reliability in a competitive market. In a world where connectivity and performance are more critical than ever, the importance of rigorous cable testing cannot be overstated.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy