cable heat pressure test

Understanding Cable Heat Pressure Tests A Comprehensive Overview

Cable heat pressure tests are vital in ensuring the safety and performance of electrical cables under stress. These tests simulate real-world conditions that cables may face in various applications, ranging from industrial machinery to household wiring. Proper testing is crucial for identifying weaknesses and preventing failures that could lead to catastrophic outcomes.

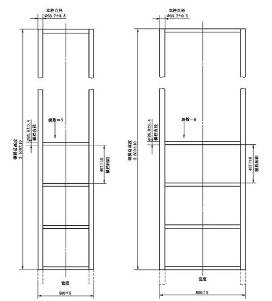

The principle behind cable heat pressure testing is straightforward. It involves applying heat and pressure to a cable while monitoring its response. This process helps determine the cable’s ability to withstand extreme conditions, assessing its insulation integrity and overall durability. During the test, cables are subjected to elevated temperatures, which may cause the insulation material to expand or degrade. By measuring how cables behave under these conditions, manufacturers can gain insights into their reliability and performance.

One of the critical aspects of these tests is to replicate the effects of thermal cycling, which can occur due to fluctuating temperatures in real-life applications. Cables often experience variations in temperature, resulting in mechanical stress that can lead to wear and tear over time. By conducting heat pressure tests, engineers can observe the long-term effects of such thermal cycling and predict the lifespan of the cable.

cable heat pressure test

Furthermore, these tests also evaluate how well the cable can handle high-pressure situations, which may arise from physical stress or environmental factors. Cables must maintain integrity when subjected to different forms of pressure, ensuring they can continue to transmit power safely. The results of such tests not only dictate the suitability of cables for specific applications but also help in formulating industry standards.

Conducting cable heat pressure tests involves sophisticated equipment and skilled personnel to interpret the data accurately. Manufacturers rely on these results to improve their products continually. By investing in rigorous testing protocols, they not only comply with industry regulations but also enhance customer trust through verified quality.

In conclusion, cable heat pressure tests are an essential component of cable manufacturing and quality assurance. These tests safeguard against potential failures, ensuring that cables deliver reliable performance throughout their operational life. As technology advances, the methodology behind these tests continues to evolve, further strengthening the foundation of electrical safety and efficiency in our daily lives.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy