Cable Heat and Pressure Testing Equipment Manufacturers for Quality Assurance Solutions

Understanding Cable Heat Pressure Test Manufacturers

In the ever-evolving world of electrical engineering and manufacturing, ensuring the safety and reliability of cables is paramount. One of the critical tests employed to assess the performance and resilience of cables is the heat pressure test. This test is pivotal in determining the cable's ability to withstand thermal stress during operation, which is essential for preventing failures and ensuring a long service life. As a result, the demand for specialized manufacturers who understand the intricacies of cable heat pressure testing has significantly grown.

What is a Cable Heat Pressure Test?

A cable heat pressure test involves exposing a cable to controlled temperature and pressure conditions to simulate the operational stresses it might encounter in real-world applications. The primary goal is to observe how the insulation material and conductor behave under elevated temperatures and pressure, which can reveal potential weaknesses or failure points. The test aims to ensure that cables can safely handle the heat generated during continuous usage without degrading or failing.

During the testing process, manufacturers will often monitor several parameters, including thermal conductivity, resistance to electrical breakdown, and the overall integrity of the cable's insulation under stress. The insights gained from these tests are crucial for manufacturers to further refine their products, ensuring they meet industry standards and client expectations.

The Importance of Qualified Manufacturers

Given the critical nature of cable heat pressure testing, working with qualified manufacturers is essential. Reliable manufacturers not only possess the necessary testing equipment but also have the expertise to conduct comprehensive evaluations. They are familiar with the various standards and regulations governing cable manufacturing, such as those set forth by the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL). Compliance with these standards not only ensures safety but also boosts confidence in the products offered.

cable heat pressure test manufacturers

When selecting a manufacturer, it's vital to consider their experience in cable heat pressure testing. Established companies often have a track record of conducting rigorous testing and developing cables that have been proven in the field. Additionally, they should invest in the latest technology to provide accurate test results, helping to identify any potential issues before cables are deployed in critical applications.

Innovations in Cable Designing and Testing

The cable manufacturing industry is witnessing remarkable innovations driven by advancing technology. Today's manufacturers utilize sophisticated testing methods, including automated systems that provide real-time monitoring of test conditions. This technological advancement allows for greater accuracy in test results and quicker responses to any inconsistencies observed during testing.

Moreover, many manufacturers are integrating sustainable practices into their operations. This includes using eco-friendly materials and methodologies that reduce waste and energy consumption during production and testing. As sustainability becomes more important to consumers and businesses alike, manufacturers that can balance performance with environmental responsibility are likely to gain a competitive advantage in the market.

The Future of Cable Heat Pressure Testing

Looking ahead, the cable heat pressure testing industry is expected to continue evolving. As electrical systems become more complex and the demand for reliable infrastructure grows, manufacturers will need to explore new materials and designs that can withstand increasingly challenging conditions. Research into nanotechnology and advanced polymer materials offers promising avenues for enhancing cable performance while maintaining safety.

In conclusion, cable heat pressure testing is a crucial component of ensuring the reliability and safety of electrical cables. As the industry continues to innovate and adapt to new technologies and sustainability practices, the role of manufacturers becomes even more critical. Businesses seeking reliable cable solutions should prioritize partnerships with experienced manufacturers who not only understand the technical requirements but are also committed to delivering high-quality, tested, and compliant products. With the right collaboration, the future of cable safety and performance looks promising.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

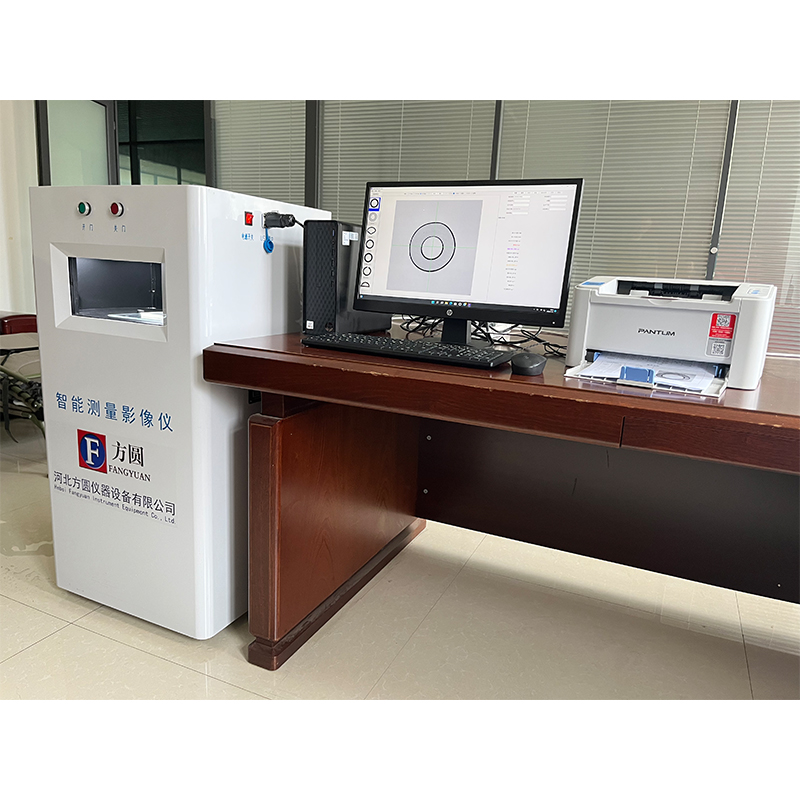

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy