cable hot set testing

Hot Set Testing for Cable Systems Ensuring Reliability and Performance

In the age of rapidly advancing technology, the performance and reliability of cable systems are more critical than ever. One essential method to ascertain these attributes is through hot set testing. This type of testing is particularly significant in the fabrication and evaluation of various cable types, ensuring they meet industry standards and customer expectations.

Hot Set Testing for Cable Systems Ensuring Reliability and Performance

One critical aspect of hot set testing is the measurement of the set characteristics of the insulation material. During the test, a specified load is applied to the cable sample at a predetermined high temperature. The material is then allowed to cool down under the load, and any changes in its dimensions are measured. This is crucial as over time, materials can experience shrinkage or other forms of deformation, which could compromise their ability to insulate effectively. The results from these tests provide valuable data regarding thermal stability and can help manufacturers make informed decisions about material selection and product design.

cable hot set testing

Moreover, hot set testing serves as a quality control measure. By routinely testing samples during production, manufacturers can ensure that their cables consistently meet the required thermal performance specifications. Any deviations observed in the results can signal issues in the manufacturing process or with the raw materials used, allowing for timely adjustments that mitigate the risk of faulty products reaching the market.

In sectors where cables are subjected to extreme conditions, such as in electrical utilities, aerospace, and automotive applications, the importance of hot set testing cannot be overstated. For example, in the aerospace industry, cables must withstand varying temperatures and environmental stresses. Conducting thorough hot set tests can help guarantee that these cables will perform reliably throughout their intended lifecycle, thus ensuring safety and operational efficiency.

As technology continues to evolve, the demand for more sophisticated cable systems is on the rise, particularly with the integration of renewable energy sources and advancements in electric vehicles. These developments necessitate rigorous testing protocols to ensure that newer cable designs can handle increased loads and temperatures. Hot set testing will undoubtedly play a vital role in this realm, helping to foster innovations that prioritize both safety and performance.

In conclusion, hot set testing is a critical component in the evaluation and verification of cable systems. By providing insights into the thermal behavior and mechanical integrity of insulated cables, manufacturers can deliver high-quality products that meet or exceed industry standards. As the demand for reliable and efficient cable systems grows, hot set testing will remain a cornerstone of quality assurance, ensuring that cables can perform optimally in the most challenging environments.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

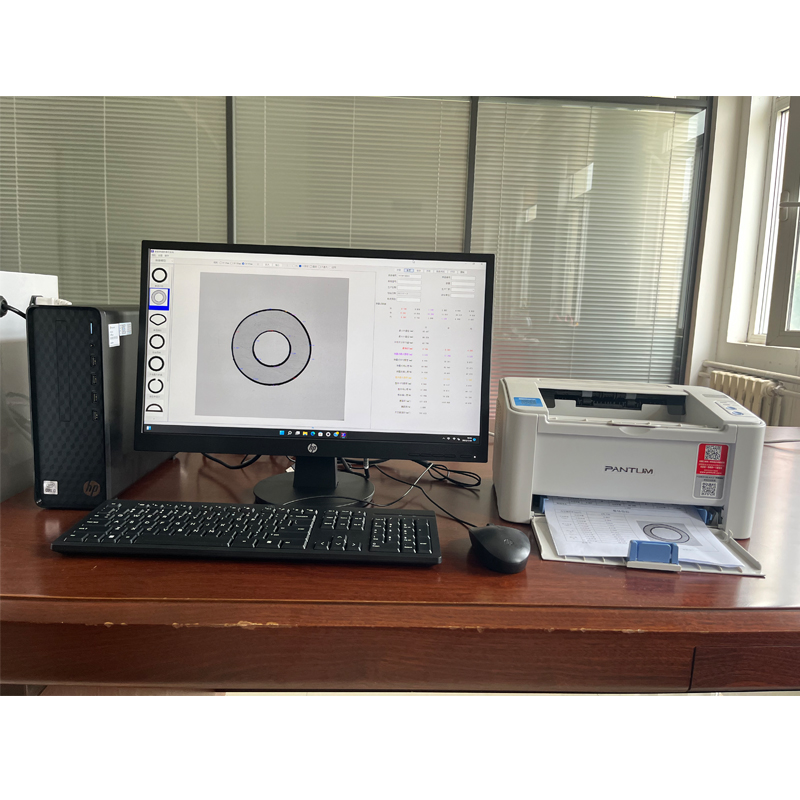

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy