cable hot set testing manufacturers

The Importance of Hot Set Testing in Cable Manufacturing A Focus on Key Manufacturers

Cable manufacturing is a crucial industry that underpins many sectors, from telecommunications to power distribution. Among the myriad of quality control tests, hot set testing stands out as a critical procedure to ensure that cables will perform reliably under various environmental conditions. This article delves into the significance of hot set testing, its methodology, and highlights prominent manufacturers that excel in this domain.

What is Hot Set Testing?

Hot set testing evaluates a cable's performance at elevated temperatures. It assesses how well the cable material withstands heat exposure, simulating conditions that cables may encounter during their operational life. The procedure involves stretching a sample cable specimen to a predetermined length while simultaneously applying heat. The key metrics recorded are the amount of elongation and the recovery behaviour after the stress is released. This information is essential for understanding the physical properties and thermal stability of the materials used in the cables.

Importance of Hot Set Testing

1. Material Durability One primary objective of hot set testing is to ascertain the durability of cable insulation and jacketing materials. Cables are often subjected to high temperatures, especially in industrial environments. By conducting this test, manufacturers can ensure their products won’t degrade or fail when exposed to heat.

2. Regulatory Compliance Various international standards govern cable performance, especially in critical applications such as aerospace, automotive, and construction. Hot set testing is often a mandatory requirement to comply with these regulations, ensuring safety and reliability.

3. Enhancing Product Reliability Reliability is paramount in cable applications where failure can lead to significant operational disruptions or safety hazards. Rigorous hot set testing provides manufacturers with vital data to refine their materials and products, thus enhancing overall reliability and performance.

4. Market Competitiveness As the cable market grows, manufacturers must differentiate themselves through product quality. Hot set testing not only ensures high standards but also acts as a marketing tool, demonstrating a commitment to quality and performance to potential clients.

cable hot set testing manufacturers

Leading Manufacturers in Hot Set Testing

Several manufacturers have made their mark by integrating rigorous hot set testing in their production processes. Here are a few notable ones

1. Nexans With a strong reputation in the global cable industry, Nexans effectively employs hot set testing to develop high-performance cables known for their durability and reliability. They focus on continuous innovation, ensuring their products meet the highest industry standards.

2. Prysmian Group This Italian company is a leader in the energy and telecommunications cable sector. Prysmian Group utilizes advanced hot set testing methodologies in their R&D, resulting in cables that perform exceptionally well even under extreme conditions.

3. Southwire An established name in the cable manufacturing industry, Southwire applies hot set testing rigorously to maintain its commitment to safety and quality. Their focus on sustainable practices also informs their testing protocols, ensuring that their products not only meet current needs but are also environmentally responsible.

4. General Cable Now part of the Marmon Group, General Cable is another key player focused on hot set testing to ensure their products are resilient. Their extensive range of cables for different industries benefits significantly from this testing method.

Conclusion

Hot set testing is an indispensable part of the cable manufacturing process, ensuring that products not only meet but exceed stringent quality standards. As the industry continues to evolve with new materials and technologies, leading manufacturers that excel in hot set testing will undoubtedly play a pivotal role in driving innovation and upholding the reliability of cable systems globally. By investing in robust testing methodologies, these companies not only safeguard their products but also contribute to the overall safety and efficiency of the industries they serve.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

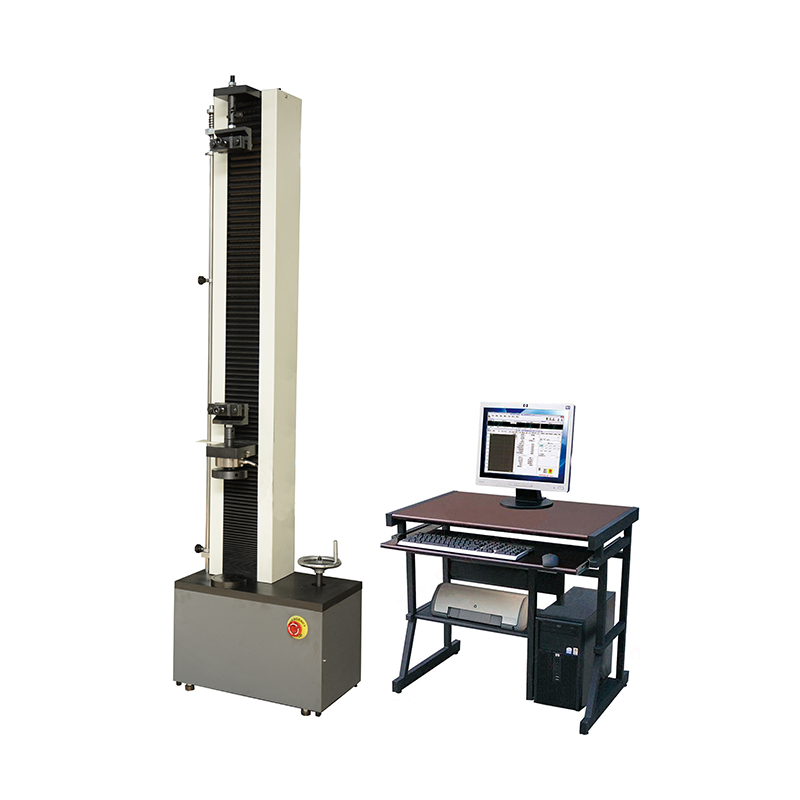

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy