cable insulation cut machine companies

The Evolution and Importance of Cable Insulation Cut Machines in Modern Industry

In today's fast-paced manufacturing environment, cable insulation cut machines play a pivotal role in the production and processing of electrical cables. As industries continue to evolve, the demand for efficient and precise manufacturing processes has significantly increased. Cable insulation cut machines have become essential tools for companies looking to enhance productivity and ensure quality in their products.

Understanding Cable Insulation Cut Machines

Cable insulation cut machines are specialized equipment designed to cut and strip the insulation from electrical cables. By automating the insulation removal process, these machines not only improve efficiency but also reduce the risk of human error. The machines are widely used in various sectors, including automotive, telecommunications, and electronics, where high-quality cables are crucial for safety and performance.

The basic functionality of these machines involves feeding the insulated cable into the system, where it is accurately measured and cut according to preset specifications. The insulation is removed with precision, ensuring that the exposed wire is left intact and undamaged. This process is vital for preparing cables for further assembly or connection to other components.

Advantages of Cable Insulation Cut Machines

1. Increased Efficiency Traditional methods of cable insulation cutting are often labor-intensive and time-consuming. Cable insulation cut machines streamline this process, allowing for faster production times. High-speed machines can process multiple cables simultaneously, significantly increasing output.

2. Enhanced Precision With advanced technology, modern machines offer precise cutting and stripping capabilities. This precision ensures that the insulation is removed without damaging the underlying wire, which is critical for maintaining the integrity and reliability of electrical connections.

3. Reduced Labor Costs Automating the insulation cutting process reduces the need for manual labor, thus decreasing labor costs. While initial investments in machinery can be significant, the long-term savings in labor and increased output often justify the expense.

4. Improved Safety Manual cutting and stripping can lead to injuries from sharp tools and improper handling. By using cable insulation cut machines, companies can promote a safer work environment, minimizing the risk of accidents and injuries among employees.

cable insulation cut machine companies

5. Scalability Businesses can easily scale production to meet growing demands. Whether a company is producing cables in small quantities for specialized applications or manufacturing thousands of units for widespread distribution, cable insulation cut machines can adapt to varying production volumes.

The Market Landscape

As the demand for high-quality insulated cables continues to climb, so does the market for cable insulation cut machines. Companies specializing in this equipment have emerged, offering a range of machines that cater to different needs and budgets. From small-scale operations to large manufacturing plants, there is a machine designed to meet the specific requirements of various businesses.

Among the leading players in the market are established manufacturers known for their innovative engineering and technological advancements. These companies are continually improving their products, incorporating features such as programmable settings, real-time monitoring, and integration with other manufacturing systems.

Future Trends

Looking ahead, the future of cable insulation cut machines is promising. As technologies such as Industry 4.0 and the Internet of Things (IoT) gain traction, manufacturers are expected to adopt smarter machines that offer enhanced connectivity and data analytics capabilities. This shift will enable businesses to optimize their production lines, monitor equipment performance, and make informed operational decisions based on real-time data.

Additionally, sustainability is becoming a critical focus for many industries. Companies are increasingly looking for machines that minimize waste and utilize energy-efficient technologies. Manufacturers that prioritize sustainability in their product designs are likely to gain a competitive edge in the market.

Conclusion

Cable insulation cut machines are indispensable tools in the manufacturing sector, driving efficiency, precision, and safety. As industries continue to evolve, the importance of these machines will only grow. Businesses that invest in high-quality insulation cutting technology stand to reap significant benefits, positioning themselves for success in an increasingly competitive landscape. As we move forward, embracing innovation and sustainability will be key to thriving in this dynamic industry.

-

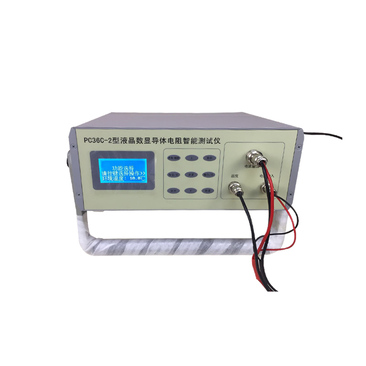

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy