cable insulation slicing machine companies

Cable Insulation Slicing Machine Companies An Overview

In the fast-paced world of manufacturing, efficiency and precision are paramount. One critical aspect of the cable manufacturing process is the removal of insulation from wires, which is essential for ensuring optimal conductivity and performance. Cable insulation slicing machines play a vital role in this process, and a number of companies specialize in producing high-quality, reliable equipment for this purpose. This article explores the leading companies in the cable insulation slicing machine market and their contributions to the industry.

Understanding Cable Insulation Slicing Machines

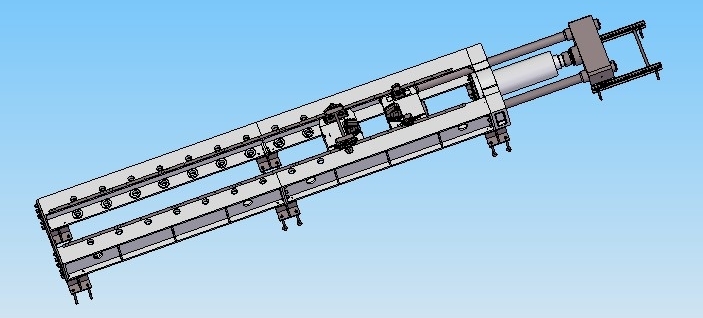

Cable insulation slicing machines are designed to strip away the insulation layer from cables with accuracy and speed. These machines utilize various technologies, including automatic feeding systems and advanced cutting blades, to ensure a clean and precise cut. The primary goal is to prepare wires for further processing, such as cabling or terminal attachment, while minimizing waste and protecting the integrity of the conductor materials.

Key Players in the Industry

1. Schleuniger One of the foremost names in the cable processing industry, Schleuniger offers a range of cutting and stripping machines designed for various wire sizes and insulation types. Their equipment is known for its robustness and user-friendly interfaces, making them a preferred choice for manufacturers looking to optimize their production processes.

2. Komax Komax is another leading manufacturer specializing in wire processing technology. Their cable insulation slicing machines are renowned for their precision and integration with automation systems, which help reduce labor costs and increase production rates. Komax continually invests in research and development to innovate and adapt to evolving market needs.

3. ARTOS Engineering ARTOS Engineering focuses on providing tailored solutions for their clients in the wire and cable industry. Their slicing machines are designed with versatility in mind, allowing adjustments for various wire sizes and insulation materials. This adaptability makes them a robust choice for manufacturers with diverse product lines.

cable insulation slicing machine companies

4. Universal Laser Systems This company stands out in the market by integrating laser technology into their cable slicing machines. Laser cutting provides unparalleled precision and minimizes mechanical wear. Universal Laser Systems' technology often results in cleaner cut edges and higher-quality output, making it an attractive option for companies focused on high-quality production.

5. Wagner Wagner specializes in custom machinery for wire processing, including cable insulation slicing machines. They offer unique features such as programmable cutting lengths and adjustable slicing depths, enabling manufacturers to tailor the machines according to their specifications. Wagner’s commitment to customer satisfaction and technological advancements has earned them a loyal client base.

Future Trends in Cable Insulation Slicing Technology

The advancements in cable insulation slicing technology are influenced by several trends. Automation is at the forefront, with more manufacturers leaning towards fully automated systems that reduce the need for human intervention. Additionally, the push for sustainability has led companies to develop machines that can handle eco-friendly insulation materials, thus promoting greener manufacturing practices.

Moreover, the integration of smart technology is rapidly transforming the industry. Data-driven insights are helping manufacturers optimize processes and improve productivity. Innovations such as real-time monitoring and predictive maintenance are becoming commonplace, ensuring machines operate at peak efficiency and reducing downtime.

Conclusion

As the demand for high-quality cables continues to grow across various industries, the significance of cable insulation slicing machines cannot be understated. Companies like Schleuniger, Komax, ARTOS Engineering, Universal Laser Systems, and Wagner are at the helm of this technological evolution, providing innovative solutions that cater to the needs of modern manufacturers. The future of cable insulation slicing machines looks promising with ongoing advancements, which will undoubtedly enhance production processes and improve the overall quality of cable manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy