cable insulation slicing machine company

The Importance of Cable Insulation Slicing Machines in Modern Manufacturing

In the rapidly advancing world of technology and manufacturing, the demand for precision and efficiency is paramount

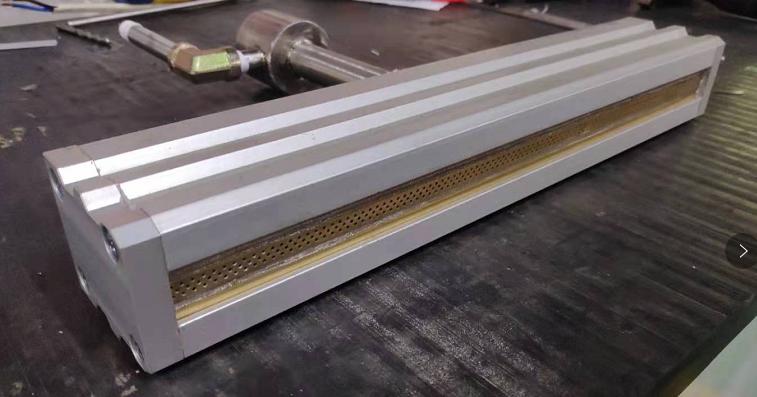

. One of the unsung heroes in this landscape is the cable insulation slicing machine. These machines play a crucial role in the production of various electrical components, ensuring that cables are properly stripped and ready for use in diverse applications ranging from telecommunications to automotive systems.Cable insulation slicing machines are designed to remove the outer sheath of cables with utmost precision. This process is vital because it prepares the cables for further processing, such as the attachment of connectors or the integration into more complex electronic systems. The effectiveness of these machines significantly impacts the overall quality and reliability of the end products. In a world where even the slightest flaw can lead to failures or hazards, the precision offered by these machines cannot be overstated.

Manufacturers globally are increasingly adopting automated solutions, and cable insulation slicing machines are a perfect example of this trend. Unlike manual methods, which can be time-consuming and prone to human error, these machines operate with high efficiency and accuracy. They are equipped with state-of-the-art technology that allows for adjustable slicing depths, ensuring that insulation is removed without damaging the underlying conductors. This capability not only enhances productivity but also improves safety standards in production environments.

cable insulation slicing machine company

Moreover, the versatility of cable insulation slicing machines makes them indispensable in various industries. Different types of cables, from coaxial and fiber optic to power cables, require specific insulation removal techniques. Modern machines can be easily adapted to handle a wide range of cable types and sizes, making them valuable assets for manufacturers looking to streamline their operations. This adaptability is particularly important in an era where customization and rapid response to market demands are critical.

Another significant advantage of employing cable insulation slicing machines is the reduction of material waste. With precise slicing capabilities, these machines minimize the amount of scrap generated during the production process. This not only leads to cost savings but also aligns with the growing emphasis on sustainability in manufacturing practices. Companies are increasingly recognizing the importance of reducing their environmental footprint, and efficient cable processing plays a pivotal role in achieving these goals.

Investing in high-quality cable insulation slicing machines can also lead to improved workforce morale and productivity. By reducing the manual workload and the physical strain on employees, manufacturers can create a more efficient and safer work environment. Additionally, employees can focus on more skilled tasks that require critical thinking and problem-solving, further enhancing overall productivity and job satisfaction.

In conclusion, cable insulation slicing machines are a vital component of modern manufacturing within the electrical and telecommunications industries. Their ability to provide precision, efficiency, adaptability, and waste reduction makes them indispensable in today’s fast-paced production environments. As technology continues to evolve, the role of these machines will only become more significant, ensuring that businesses can meet consumer demands with high-quality, reliable products. Companies investing in advanced cable insulation slicing technology position themselves not only to enhance their operational capabilities but also to lead the way towards more sustainable and innovative manufacturing practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy