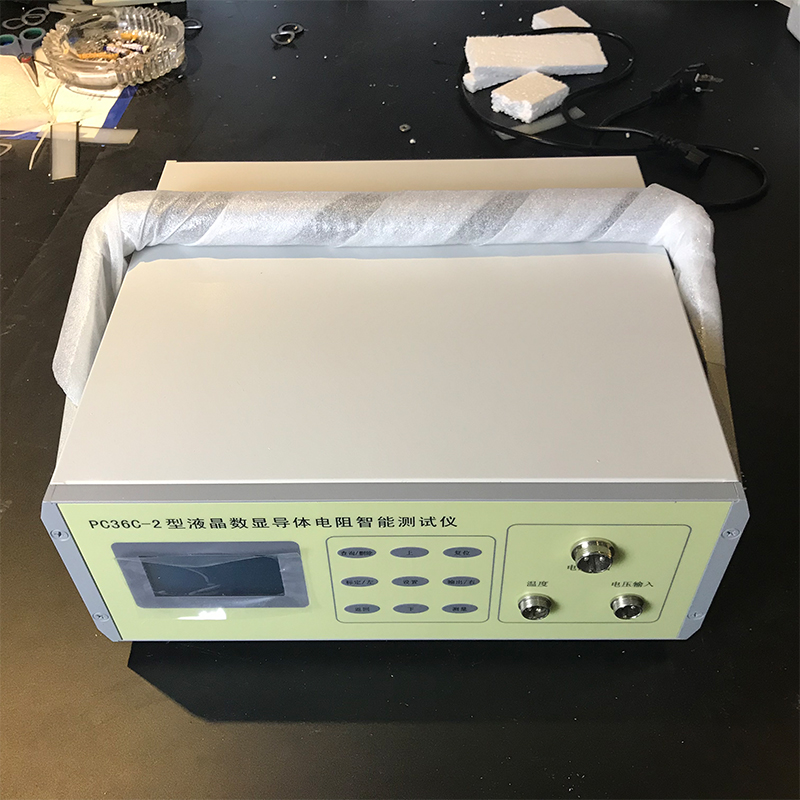

cable load burning test machine supplier

The Importance and Functionality of Cable Load Burning Test Machines

In the realm of electrical engineering and manufacturing, ensuring the safety and reliability of cabling products is crucial. One of the key methods employed to evaluate these characteristics is the cable load burning test. It is a rigorous process that assesses the performance of cables under extreme conditions, particularly regarding their reaction to fire. As such, the demand for high-quality cable load burning test machines has grown significantly. This article explores the essential features, suppliers, and the importance of these machines in the industry.

What is a Cable Load Burning Test Machine?

A cable load burning test machine is specifically designed to simulate extreme electrical conditions that cables may encounter. It typically involves applying a specific load to the cable while subjecting it to a controlled fire environment. This test is vital for determining both the thermal stability and combustion characteristics of various types of cables. Products are examined for their ability to withstand heat, avoid ignition, and limit the spread of flames or harmful gases.

Key Features of Cable Load Burning Test Machines

1. Controlled Environment Quality test machines feature advanced control systems that ensure the environment's temperature, pressure, and other variables are strictly regulated. This is integral to providing accurate and repeatable results.

2. Load Application These machines can apply specified electrical loads to the cables to simulate real-life operational conditions. This feature helps identify potential weak points in the cable’s design.

3. Data Logging and Analysis Modern test machines are equipped with sophisticated data logging systems, capturing critical metrics throughout the testing process. This data is essential for subsequent analysis and quality assurance.

4. Safety Features Given the dangers associated with fire tests, these machines are usually designed with various safety measures. Features may include automatic shut-off systems, fire suppression capabilities, and materials that can withstand high temperatures.

5. Compliance with Standards Reputable suppliers ensure that their machines comply with international testing standards such as IEC, UL, and others. This adherence is crucial for manufacturers aiming to certify their products for market entry.

Choosing the Right Supplier

cable load burning test machine supplier

When sourcing a cable load burning test machine supplier, there are several factors to consider

- Reputation and Experience Look for suppliers with a solid reputation in the industry and years of experience in manufacturing testing equipment. Reading customer reviews and seeking testimonials can provide valuable insights into a supplier's reliability.

- Technical Support Opt for suppliers that offer comprehensive technical support, including installation, calibration, and troubleshooting assistance. This support is essential, especially when dealing with complex testing equipment.

- Customization Some manufacturers may have specific testing requirements based on their product range. A flexible supplier who can customize machines to meet unique needs can be invaluable.

- Quality and Compliance Ensure that the supplier adheres to stringent quality control measures in their manufacturing processes. Additionally, check if their machines meet international safety and quality standards.

The Significance of Cable Load Burning Testing

Conducting cable load burning tests has become increasingly mandatory in various sectors, including construction, automotive, and telecommunications. The importance of these tests extends beyond mere compliance; they play a pivotal role in minimizing risks associated with electrical fires.

Through these tests, manufacturers can identify potential weaknesses in their products and innovate designs to enhance safety and performance. This proactive approach not only protects consumers but also builds trust and credibility in the market.

Moreover, stringent safety regulations enforced by governmental and regulatory bodies necessitate that manufacturers utilize effective testing methodologies. Thus, having an indispensable tool like a cable load burning test machine is pivotal for companies aiming to protect their brand and ensure the safety of their products.

Conclusion

As electrical products become more ubiquitous in our daily lives, the importance of safety cannot be overstated. Cable load burning test machines have emerged as crucial tools in the evaluation and enhancement of cable safety and performance. By carefully selecting a reliable supplier and utilizing advanced testing methodologies, manufacturers can significantly improve product safety and reliability, ensuring they meet the growing demands of the market. Investing in high-quality testing equipment ultimately leads to a safer environment for end-users and a stronger reputation for manufacturers in the competitive electrical market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy