Cable Length Measurement Device for Accurate Industry Applications and Quality Assurance

Cable Measurement Machine Revolutionizing Cable Production Quality Control

In the modern era of industrialization, optimizing manufacturing processes and ensuring product quality has become a top priority for companies across various sectors. One significant advancement in this regard is the introduction of the cable measurement machine. This innovative tool is designed to measure the dimensions and parameters of cables with precision and efficiency, thereby enhancing the quality control processes in cable manufacturing.

What is a Cable Measurement Machine?

A cable measurement machine is a sophisticated instrument used to measure various physical attributes of cables, including length, diameter, tensile strength, and insulation thickness. These machines leverage advanced technologies such as laser measurement systems, high-resolution cameras, and sophisticated software algorithms to provide accurate readings quickly. By utilizing a cable measurement machine, manufacturers can ensure that their products meet the stringent standards required for safety and performance.

Key Features and Benefits

1. Precision and Accuracy The primary advantage of using a cable measurement machine is its ability to deliver precise measurements. Traditional measurement methods may involve manual calculations and subjective interpretation, leading to potential errors. In contrast, cable measurement machines utilize automated systems that eliminate human error, ensuring that the dimensions of cables are consistently accurate.

2. Increased Efficiency Cable production is often a fast-paced environment, where delays can lead to significant economic losses. A cable measurement machine can quickly assess multiple cables in a short amount of time, thus speeding up the quality control process. This enhancement not only reduces the time taken for inspections but also allows manufacturers to focus on other critical areas of production.

3. Data Collection and Analysis Modern cable measurement machines come equipped with data logging capabilities. This feature enables manufacturers to collect and analyze measurement data over time, providing valuable insights into production trends and potential issues. By identifying patterns and inconsistencies, manufacturers can implement corrective actions proactively, thereby reducing waste and optimizing production efficiency.

4. Compliance and Certification In many industries, cables must comply with specific safety and performance standards. A cable measurement machine can help manufacturers ensure compliance during the production process, reducing the risk of non-conformity that could lead to costly recalls or reputational harm. Furthermore, having accurate measurements readily available can expedite the certification process for new products.

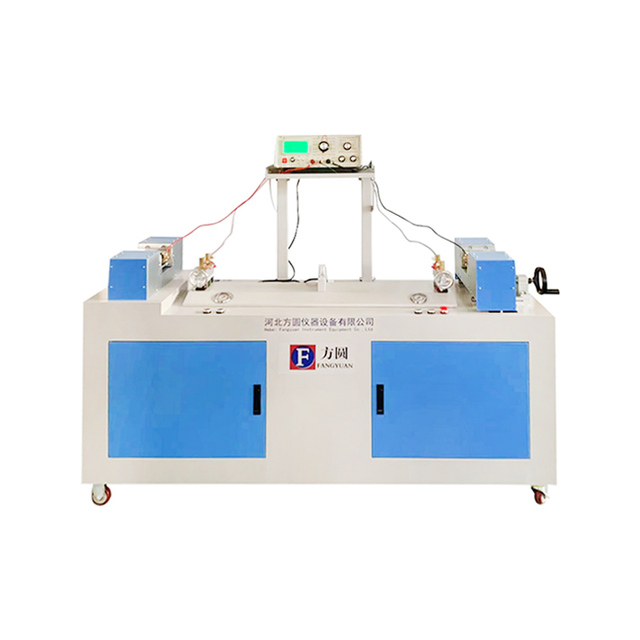

cable measurement machine

5. Versatility These machines are not limited to measuring only one type of cable. They can be programmed for various cable types, including power cables, optical fiber cables, and communication cables. This versatility makes them invaluable in manufacturing environments where multiple cable varieties are produced.

Applications Across Industries

Cable measurement machines find applications across a wide range of industries, including telecommunications, automotive, aerospace, and construction. In telecommunications, where high-speed data transfer is crucial, precise cable dimensions can impact signal quality. In the automotive industry, cables power various electronic systems, making consistent quality control essential for safety. Similarly, in aerospace, the integrity of cables is critical for the functionality of flight systems.

The Future of Cable Measurement Technology

As technology continues to evolve, so too will the capabilities of cable measurement machines. Integration with the Internet of Things (IoT) is on the horizon, allowing these machines to be connected to broader production monitoring systems. This connectivity will enable real-time data analysis and monitoring, making quality assurance an even more streamlined process.

Moreover, advancements in artificial intelligence (AI) may further enhance the precision and efficiency of cable measurement machines. AI algorithms could learn from historical data to predict potential quality issues before they occur, providing manufacturers with a proactive approach to quality control.

Conclusion

The cable measurement machine represents a significant step forward in ensuring the quality and reliability of cable products in various industries. By embracing this technology, manufacturers can optimize their production processes, enhance efficiency, and maintain compliance with industry standards. As the demand for high-quality cables continues to grow, the importance of such measurement machines will undoubtedly increase, cementing their place as essential tools in the modern manufacturing landscape.

-

QNJ-2/3 Cable Flexibility Test Machine: Precision & Durability

NewsAug.31,2025

-

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

-

Advancing Precision with Profile Projector Technology

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy