Cable Measurement Equipment Supplier for Precision and Efficiency in Manufacturing

The Role of Cable Measurement Machines in the Cable Manufacturing Industry

In today's highly competitive manufacturing landscape, precision and accuracy are paramount, particularly in the production of cables used across various industries. From telecommunications to automotive applications, the quality of cables significantly affects performance and safety. This is where cable measurement machines (CMMs) come into play, serving as vital tools for manufacturers to ensure their products meet the required specifications. In this article, we will explore the importance of cable measurement machines, their functionalities, and why investing in high-quality equipment from reputable manufacturers is essential.

What is a Cable Measurement Machine?

Cable measurement machines are specialized devices designed to measure various physical properties of cables. These properties include length, diameter, impedance, capacitance, and tensile strength. Different types of cables, such as coaxial, fiber optic, and power cables, often have unique requirements that necessitate precise measurements to ensure optimal performance in their applications.

CMMs typically come equipped with advanced sensors and software that can provide real-time data analysis. The use of such technology allows manufacturers to detect discrepancies during the production process, enabling timely corrections that maintain product integrity.

The Importance of Cable Measurement Machines

1. Quality Assurance In sectors like aerospace, automotive, and telecommunications, the reliability of cables is non-negotiable. Any defect can lead to catastrophic failures. CMMs guarantee that every batch of cables adheres to strict quality standards, significantly reducing the likelihood of failure in the field.

2. Regulatory Compliance Many industries are governed by strict regulations that mandate specific testing and certification of cables. Utilizing CMMs helps manufacturers comply with these regulations, avoiding costly fines and maintaining their reputation in the market.

3. Cost Efficiency Catching defects during the measurement process is far less expensive than dealing with returns or warranty claims later. By investing in CMMs, manufacturers can save money and resources, ultimately enhancing their bottom line.

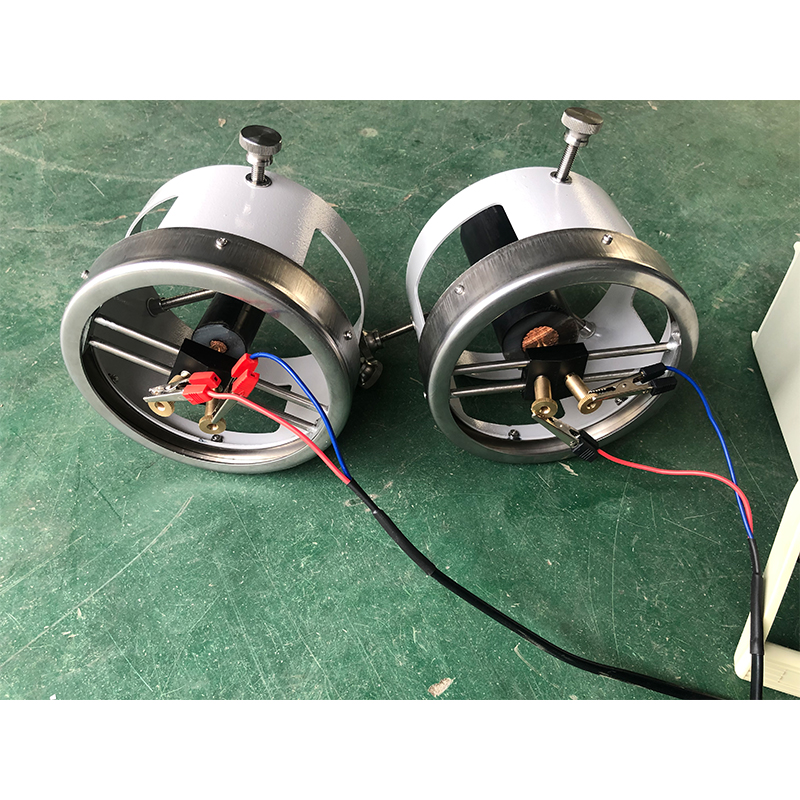

cable measurement machine manufacturer

4. Feedback Loop Cable measurement machines facilitate a continuous feedback loop in the manufacturing process. Data collected during measurements can inform adjustments to production lines, ensuring that quality is consistently maintained.

Choosing the Right Manufacturer

When looking for a cable measurement machine manufacturer, several factors should be considered

1. Reputation Opt for a company that has a proven track record of quality and reliability. Reading customer reviews and seeking recommendations can provide insights into the manufacturer's credibility.

2. Technology Advanced measurement technologies, such as laser measurement, viscometry, and automated systems, can offer more precise and faster results. A good manufacturer should continually innovate and keep up with industry trends.

3. Customization Different manufacturers may have specific needs based on their cable types and production processes. A manufacturer that offers customizable CMM solutions will better cater to your unique operational requirements.

4. Support and Service Post-purchase support is crucial. Look for manufacturers that provide reliable after-sales services, including maintenance and training on how to operate the machines efficiently.

Conclusion

In the cable manufacturing industry, precision and quality are vital for success. Cable measurement machines play an indispensable role in ensuring that cables meet the required specifications and regulatory standards. By choosing the right manufacturer, companies can invest in equipment that not only enhances their production capabilities but also safeguards their reputation in a highly competitive market. As technology continues to evolve, so too will the tools available to manufacturers, further driving innovation and efficiency in cable production. The collaboration between cable manufacturers and CMM manufacturers will undoubtedly lead to improved product quality and greater customer satisfaction in the years to come.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy