cable repeated bending tester suppliers

Understanding Cable Repeated Bending Testers A Guide for Suppliers

In today's technologically advanced world, the demand for reliable and durable electrical cables has never been higher. Cables are the lifelines of power distribution and communication networks, making it imperative to ensure their resilience and longevity. One critical assessment tool in this regard is the cable repeated bending tester. This article will explore the importance of these testers, the key features to look for, and the role of suppliers in meeting industry standards.

What is a Cable Repeated Bending Tester?

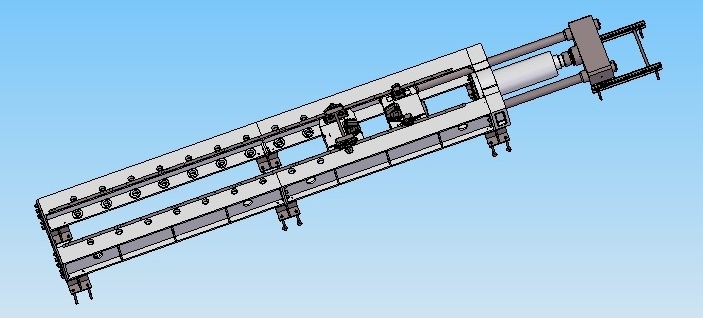

A cable repeated bending tester is a specialized machine designed to evaluate the mechanical strength and durability of cables under repeated bending conditions. This testing simulates the everyday stresses that cables endure when installed and utilized in various environments. The machine bends the cable at a specific radius and angle in a controlled manner, replicating the real-world conditions that lead to cable fatigue and failure. By assessing a cable's performance under these conditions, manufacturers can predict its lifespan and reliability.

Importance of Cable Testing

The importance of cable testing cannot be overstated. With the proliferation of electronic devices, industrial machinery, and communication networks, cables are subjected to a variety of mechanical stresses. Inadequate testing can lead to catastrophic failures, resulting in equipment downtime, financial losses, and safety hazards. Therefore, implementing stringent quality control measures, including repeated bending tests, is vital for manufacturers looking to deliver trustworthy products.

Key Features of a Cable Repeated Bending Tester

When looking for a cable repeated bending tester, suppliers should consider several critical features to ensure optimal performance

1. Adjustable Bending Radius and Angle The ability to customize the bending radius and angle allows for a comprehensive simulation of real-world conditions. This versatility is essential for testing a wide range of cable types and sizes.

2. Durability and Build Quality Since repeated bending tests subject the machine to significant wear and tear, a tester must be built from high-quality materials to ensure long-term reliability.

cable repeated bending tester suppliers

3. User-Friendly Interface An intuitive control panel that allows for easy operation and monitoring of the testing process is crucial. Ideally, the system should feature digital displays for real-time data tracking.

4. Automated Testing Cycle Automated systems can conduct tests with minimal human intervention, reducing the likelihood of errors and increasing efficiency in quality control processes.

5. Data Analysis and Reporting The capability to analyze results and generate reports is essential for manufacturers to review performance metrics and compliance with industry standards.

6. Safety Features Built-in safety mechanisms, such as emergency stop functions and protective enclosures, are vital to ensure safe operation during testing.

The Role of Suppliers in Quality Assurance

Suppliers of cable repeated bending testers play a crucial role in ensuring that manufacturers have access to high-quality testing equipment. It is essential for suppliers to stay abreast of technological advancements and industry standards to meet their clients' needs effectively. They must offer machines that not only comply with international testing standards but also provide robust after-sales support, including maintenance and calibration services.

In addition to providing equipment, suppliers should also offer training programs for manufacturers. Proper training ensures that operators understand how to use the equipment effectively, interpret results accurately, and comply with safety regulations. Such educational initiatives foster a culture of quality assurance, ultimately leading to more dependable products in the market.

Conclusion

In summary, cable repeated bending testers are indispensable tools for manufacturers striving to enhance the durability and reliability of their products. By incorporating advanced features and adhering to industry standards, suppliers can provide essential equipment that supports rigorous quality assurance processes. As the demand for high-quality cables continues to grow, the role of suppliers in facilitating effective testing becomes increasingly vital. Investing in quality testing equipment not only ensures compliance with safety regulations but also enhances customer trust and brand reputation in the competitive market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy