cable repeated bending test machine

Understanding the Cable Repeated Bending Test Machine Importance and Applications

In today's rapidly advancing technological landscape, the integrity and reliability of electrical cables are paramount in ensuring efficient power distribution and communication systems. One critical method of evaluating the performance of cables under mechanical stress is through the use of a cable repeated bending test machine. This specialized piece of equipment simulates the dynamic bending that cables experience in real-world applications, allowing manufacturers and researchers to assess the durability and longevity of various cable types.

Purpose of the Cable Repeated Bending Test Machine

The primary purpose of a cable repeated bending test machine is to replicate the conditions that cables encounter during installation and usage. Cables are often subjected to bending, twisting, and stretching as they are installed in walls, ceilings, machinery, or within data centers. These dynamic conditions can lead to wear and tear over time, potentially causing failures that could disrupt services or endanger safety. By performing repeated bending tests, manufacturers can identify weaknesses in their products and improve their designs, thereby enhancing performance and reliability.

Key Features of the Testing Machine

A typical cable repeated bending test machine is equipped with various features that facilitate accurate and efficient testing. It generally includes

1. Bending Mechanism The core of the machine consists of a bending mechanism that can replicate the motion and angles of bending that cables will experience in practical use. This mechanism can be automated or manually operated, depending on the design of the machine.

2. Adjustable Parameters To accommodate different types of cables, the machine allows operators to adjust parameters such as the radius of bending, speed of operation, and the number of cycles to be performed before stopping the test. This flexibility is crucial for testing various cable sizes and materials.

3. Monitoring Systems Many advanced models come with integrated monitoring systems that provide real-time data during the test. Such systems can track parameters like temperature, strain, and the number of cycles to provide comprehensive results on the cable's performance under stress.

4. Data Analysis Software Post-test data analysis is essential for evaluating the results quantitatively. Modern test machines are often paired with software that can parse the collected data, allowing engineers and quality assurance teams to draw meaningful conclusions regarding the cable’s durability.

cable repeated bending test machine

Importance of Conducting Repeated Bending Tests

Conducting repeated bending tests using a dedicated machine offers several important benefits

- Quality Assurance Regular testing helps manufacturers maintain high-quality standards. By identifying potential failures in the design or materials used, companies can make necessary adjustments before cables reach the market.

- Regulatory Compliance Many industries have specific regulations regarding cable performance. Testing ensures compliance with these standards, thereby reducing the risk of product recalls and liability issues.

- Performance Validation For new cable designs or materials, testing helps validate the performance claims made by manufacturers. This credibility is crucial in competitive markets where consumers seek reliable products.

- Research and Development The insights gained from bending tests can guide R&D efforts. Understanding how cables perform under stress can inspire innovations in material science and engineering techniques, leading to the development of more robust cable solutions.

Practical Applications

The applications of cable repeated bending test machines extend across various industries, including telecommunications, aerospace, automotive, and construction. In telecommunications, for example, fiber optics must undergo rigorous testing to ensure they can withstand the physical demands of installation and daily use without degrading signal quality. Similarly, in the automotive sector, electrical wiring must be tested to ensure it can endure the vibrations and movements of a vehicle without failure.

Conclusion

In conclusion, the cable repeated bending test machine is an essential tool for manufacturers aiming to ensure the reliability and durability of their cable products. By accurately simulating real-world conditions, this machine not only assists in maintaining high quality and performance standards but also fosters innovation and compliance with regulatory requirements. As technology continues to evolve, the importance of such testing equipment will only increase, securing a place for the cable repeated bending test machine in the future of electrical and telecommunications industries.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

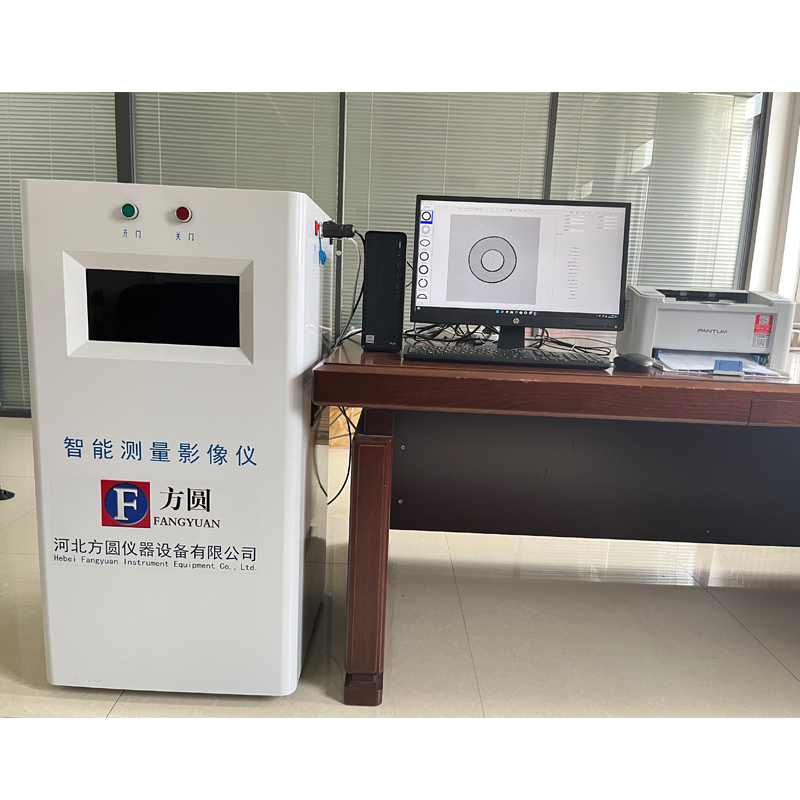

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy