Cable Repeated Bending Test Equipment Supplier for Quality Assurance Testing Solutions

The Importance of Cable Repeated Bending Test Machines A Focus on Manufacturers

In the realm of electrical engineering and electronics, the reliability of cables is paramount. Cables serve as the lifelines of connectivity, transporting power and signals in a myriad of applications. From simple household appliances to sophisticated telecommunications infrastructure, the durability and longevity of cables are critical. One of the key methods to evaluate the performance of cables under real-world conditions is the repeated bending test. This is where cable repeated bending test machines come into play, serving as essential tools for manufacturers aiming to ensure the quality and reliability of their products.

Understanding the Cable Repeated Bending Test

The cable repeated bending test simulates the mechanical stress that cables undergo during regular use. Cables are subjected to continuous flexing, which can lead to wear and tear over time. By employing a bending test machine, manufacturers can assess how well a cable copes with bending over an extended period. The machine typically clamps the cable and bends it back and forth a predetermined number of times, effectively replicating the conditions of regular usage.

The parameters measured during this testing include the cable's ability to maintain electrical integrity, potential breakage, and any physical damage to the outer jacket. The results of these tests provide vital insights into the lifespan and reliability of the cable under normal operating conditions.

The Role of Manufacturers

Cable manufacturers play a crucial role in integrating these test machines into their quality control processes. The use of reliable and precise test machinery helps them in producing high-quality cables that meet industry standards. This not only enhances the reputation of the manufacturer but also minimizes the risks associated with product failures.

When selecting a cable repeated bending test machine, manufacturers consider several factors, including the machine's capacity, the precision of bending mechanisms, and the ability to record and analyze data

. Leading manufacturers in this niche are continually innovating to provide machines that not only meet stringent regulations but also incorporate advanced technology for improved performance.cable repeated bending test machine manufacturer

Advancements in Testing Technology

The cable repeated bending test machine industry is witnessing significant advancements. Manufacturers are now integrating automation and software solutions that allow for more precise control of testing parameters and improved data analysis. Modern machines can monitor variables in real-time, provide instant feedback, and even suggest modifications to improve cable designs based on the test outcomes.

Moreover, manufacturers are focusing on making these machines more user-friendly. With touchscreen interfaces and intuitive software, operators can easily set up tests, monitor progress, and analyze results without requiring extensive technical training. This ease of use accelerates the testing process, enabling manufacturers to bring products to market quicker while maintaining high-quality standards.

Meeting Global Standards

In today’s interconnected world, adherence to global standards is vital. Many countries have specific regulations governing the quality and safety of electrical components, including cables. Manufacturers must ensure that their cables pass rigorous tests before they can be marketed. Cable repeated bending test machines aid in this process by offering a reliable means of compliance testing. They help manufacturers produce cables that not only meet local standards but can also be sold in international markets.

Conclusion

Investing in a high-quality cable repeated bending test machine is an essential strategy for manufacturers committed to delivering durable and reliable products. With the ongoing advancements in technology, these machines continue to evolve, enabling better testing capabilities and enhancing the overall manufacturing process. As industries demand more resilient and efficient cables, manufacturers that leverage these machines will be well-positioned to meet the challenges of the modern marketplace. In the end, the importance of ensuring the quality of cables cannot be overstated, as they are fundamentally entwined with the efficiency and reliability of all connected systems.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

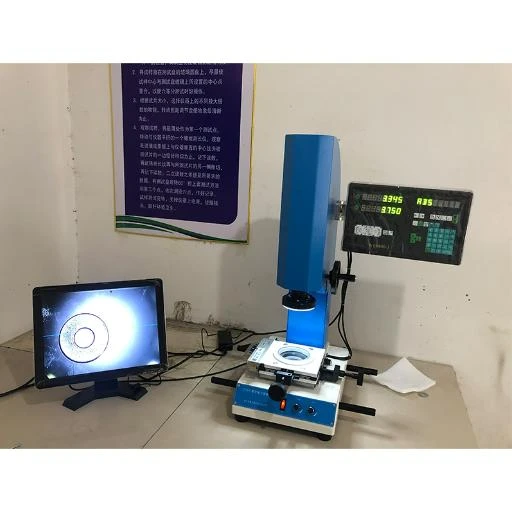

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy