Cable Sheath Cutting Machine Supplier for Efficient Wire Processing Solutions

The Growing Market for Cable Sheath Cut Machines A Focus on Exporters

In today’s rapidly advancing technological landscape, the demand for high-quality cable sheath cut machines is on the rise. These machines play a crucial role in the manufacturing and processing of electrical cables, which are essential components in various industries, including telecommunications, construction, and automotive. With the globalization of trade, countries have started exporting these specialized machines, creating opportunities for manufacturers and exporters alike.

The Importance of Cable Sheath Cutting

Cable sheath cutting is a critical process in the preparation of electrical cables for installation. The sheath, made from materials such as PVC or polyethylene, protects the inner wires from environmental factors and mechanical stress. Precise cutting of the sheath ensures that the wires are accessible for connection while maintaining the integrity of the cable structure. This ensures performance reliability, safety, and longevity of electrical systems.

As industries expand, so does the need for efficient and reliable cable sheath cutting solutions. This has led to a surge in demand for machines that can cut, strip, and prepare cables quickly and accurately. Manufacturers are increasingly looking for advanced machinery that can enhance productivity while minimizing waste, thereby driving the market for cable sheath cut machines.

Who are the Key Players?

The market for cable sheath cut machines comprises various players, including manufacturers, suppliers, and exporters. Many countries specialize in the production of these machines, including Germany, Italy, China, and the United States. Each of these countries offers a range of products with varying features, prices, and quality standards.

China, for example, has become a major player in the global market due to its cost-effective manufacturing processes. Chinese exporters offer a wide array of cable sheath cut machines, from basic models to advanced automated systems equipped with cutting-edge technology. These machines are particularly attractive to developing countries seeking affordable and efficient solutions.

Germany is renowned for its high-precision engineering and quality manufacturing. German manufacturers focus on producing top-tier machines that may come at a higher price point but offer durability and advanced functionality. Their machines often integrate sophisticated technology that can automate various aspects of the cutting process, adding value for medium to large-scale operations.

cable sheath cut machine exporter

Challenges Facing Exporters

Despite the growing demand for cable sheath cut machines, exporters face several challenges. One significant hurdle is the varying standards and regulations in different countries. Each market may have specific requirements regarding safety, efficiency, and environmental impact that machines must meet. Navigating these regulations can be complex and time-consuming for exporters.

Additionally, the competition within the market is intense. As manufacturers in various countries ramp up production, exporters must differentiate themselves through superior quality, innovative features, customer service, and competitive pricing. Building a strong brand reputation and establishing trust with clients becomes vital in securing and maintaining market share.

Future Prospects in the Export Market

Looking forward, the export market for cable sheath cut machines appears promising. With continual advancements in technology, such as automation and artificial intelligence, manufacturers are innovating to meet the evolving needs of the industry. These technological developments will likely lead to more efficient machines that can perform tasks with greater precision and speed.

Moreover, as global infrastructure projects expand, the demand for electrical cables will continue to rise, driving the need for efficient manufacturing processes. The cable manufacturing industry is poised for growth, and exporters who can adapt to changing market conditions and invest in research and development will find opportunities to thrive.

Conclusion

The market for cable sheath cut machines is witnessing significant growth globally. Exporters play a crucial role in meeting the demands of various industries by providing innovative and efficient solutions. While there are challenges, the future looks bright for those who can navigate the competitive landscape and embrace technological advancements. As industries evolve and global trade continues to expand, the need for high-quality cable sheath cut machines will only increase, offering exciting prospects for manufacturers and exporters alike.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

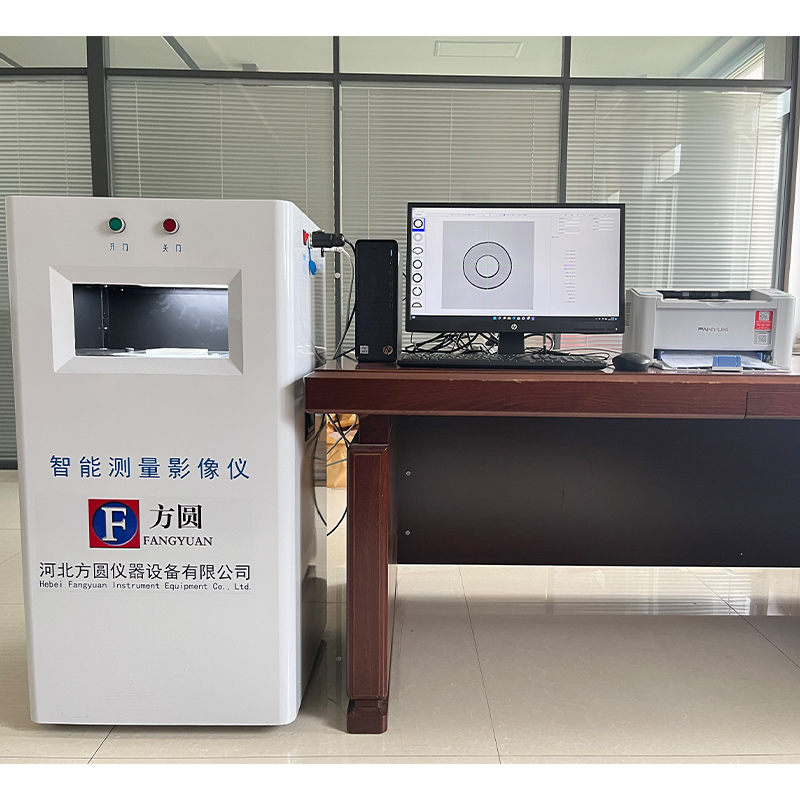

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy