Cable Sheath Cutting Machines Suppliers and Exporters for Efficient Wire Processing

The Growth of Cable Sheath Cut Machine Exporters

In an era where global connectivity is paramount, the demand for efficient cable management solutions continues to grow. Among these solutions, cable sheath cut machines have emerged as essential tools for manufacturers and industries worldwide. These machines streamline the production process by facilitating the precise cutting of cable sheathing materials, thereby enhancing operational efficiency. With the rise in technological advancements and a burgeoning market for cables, exporters of cable sheath cut machines have witnessed significant growth.

The primary function of a cable sheath cut machine is to ensure the accurate and clean cutting of various types of cable sheaths, which can be made from diverse materials such as PVC, rubber, and polyethylene. These machines are designed to meet the specific requirements of different industries, including telecommunications, automotive, and electronics. As companies strive to optimize their production processes and reduce waste, the need for reliable and efficient cutting solutions is paramount.

Exporters of cable sheath cut machines are now expanding their markets beyond traditional boundaries. Countries with robust manufacturing sectors, such as China, Germany, and the United States, are at the forefront of production and innovation in this field. These countries have established themselves as key players in the global supply chain, providing high-quality machines that cater to the varying needs of clients across different regions.

cable sheath cut machine exporters

One of the driving forces behind the growth of cable sheath cut machine exporters is the increasing demand for customized solutions

. Businesses are looking for machines that can adapt to specific production requirements, allowing for versatility in manufacturing. Exporters are responding by offering tailored solutions that meet these diverse needs, enhancing their competitiveness in the international market.Moreover, advancements in technology have played a critical role in the evolution of cable sheath cut machines. Modern machines are now equipped with features such as programmable settings, automatic feeding systems, and enhanced safety measures. These innovations not only improve cutting accuracy but also increase production speed, enabling manufacturers to meet tight deadlines and high-volume demands.

As awareness of sustainability and environmental responsibility grows, many exporters are also focusing on producing energy-efficient machines that minimize waste and reduce energy consumption. This shift aligns with global trends toward more sustainable manufacturing practices, making these machines even more appealing to potential buyers.

In conclusion, the market for cable sheath cut machine exporters is witnessing rapid expansion, driven by technological advancements and increasing global demand for efficient cable management solutions. As industries continue to evolve and seek innovative ways to enhance productivity, the role of these machines will become increasingly vital. For exporters, the opportunity to innovate and adapt to the changing landscape presents a promising pathway for growth in the years to come.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

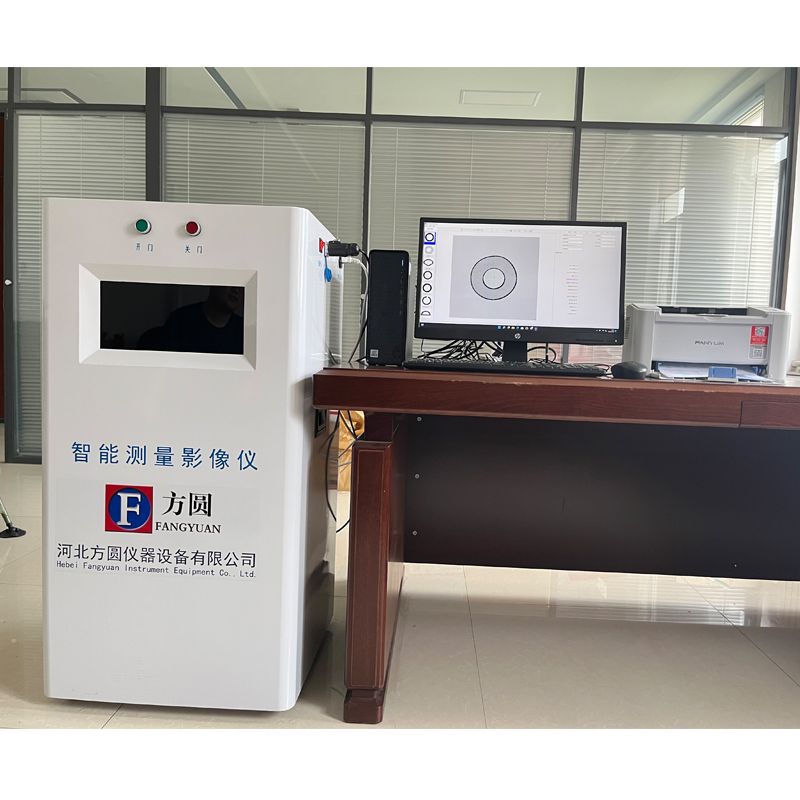

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy