cable smoke density test machine manufacturers

Understanding Cable Smoke Density Test Machines A Guide to Manufacturers

When it comes to assessing the safety of electrical cables, one of the crucial tests performed is the smoke density test. This test evaluates the amount of smoke produced by a cable when it is subjected to fire, which is essential for understanding its potential hazards in a real-world scenario. As a result, manufacturers of cable smoke density test machines play a significant role in ensuring that cables meet safety standards and regulations. This article will explore the importance of these machines, the criteria for selecting a manufacturer, and a few prominent companies in the industry.

Importance of Smoke Density Testing

Smoke density testing is vital for several reasons. Firstly, excessive smoke during a fire can impede visibility and pose severe health risks, such as respiratory issues for individuals trying to escape. As such, understanding how much smoke a cable produces is crucial for safety assessments in buildings, public transportation, and other environments where electrical cables are used. Regulatory bodies in different countries often require smoke testing to assess compliance with safety codes, making it essential for manufacturers to utilize reliable smoke density test machines.

Criteria for Choosing Manufacturers

When searching for manufacturers of cable smoke density test machines, several factors should be considered.

1. Quality and Compliance A manufacturer should provide machines that meet international testing standards such as IEC 61034 and ISO 5659. Ensuring that the equipment adheres to these standards is important for obtaining accurate and consistent results.

2. Technology and Innovation The best manufacturers often employ the latest technology in their testing machines. Features such as automated data recording, software integration, and real-time monitoring can significantly enhance the testing process, making it more efficient and reliable.

3. Customer Support and Service Given the complexity of these machines, after-sales support should be a critical consideration. Manufacturers should offer comprehensive training, maintenance services, and readily available customer support to ensure that users can operate the machines effectively.

cable smoke density test machine manufacturers

4. Reputation and Experience Consider the manufacturer’s reputation in the industry. A company with a long history of producing smoke density test machines is more likely to have a proven track record of reliability and quality.

Prominent Manufacturers

Several manufacturers have established themselves as leaders in the production of cable smoke density test machines.

1. FTT (Fire Testing Technology) Based in the UK, FTT is known for its innovative fire testing equipment. Their smoke density test machines are widely recognized for their precision and compliance with international testing standards.

2. GUNSEN A prominent manufacturer in China, GUNSEN specializes in various testing equipment, including smoke density testers. They emphasize quality control and have gained a significant market share in Asia and beyond.

3. Lloyd's Register With a legacy of safety assurance, Lloyd's Register provides advanced solutions for fire testing. They offer machines designed for smoke density and are known for their engineering excellence and reliability.

4. INTERTEK As a global leader in quality assurance, Intertek facilitates a wide range of testing services, including smoke density assessments. Their equipment is used worldwide, and they are recognized for their high standards of testing and certification.

Conclusion

In summary, cable smoke density test machines are an integral part of assessing the safety of electrical cables. Selecting a reputable manufacturer that prioritizes quality, technology, and customer support is crucial for ensuring accurate testing. With numerous manufacturers in the market, it is essential to conduct thorough research to find the right partner for your testing needs. As safety regulations become more stringent, the importance of reliable testing equipment will only continue to grow, making smoke density testing an invaluable aspect of cable safety compliance.

-

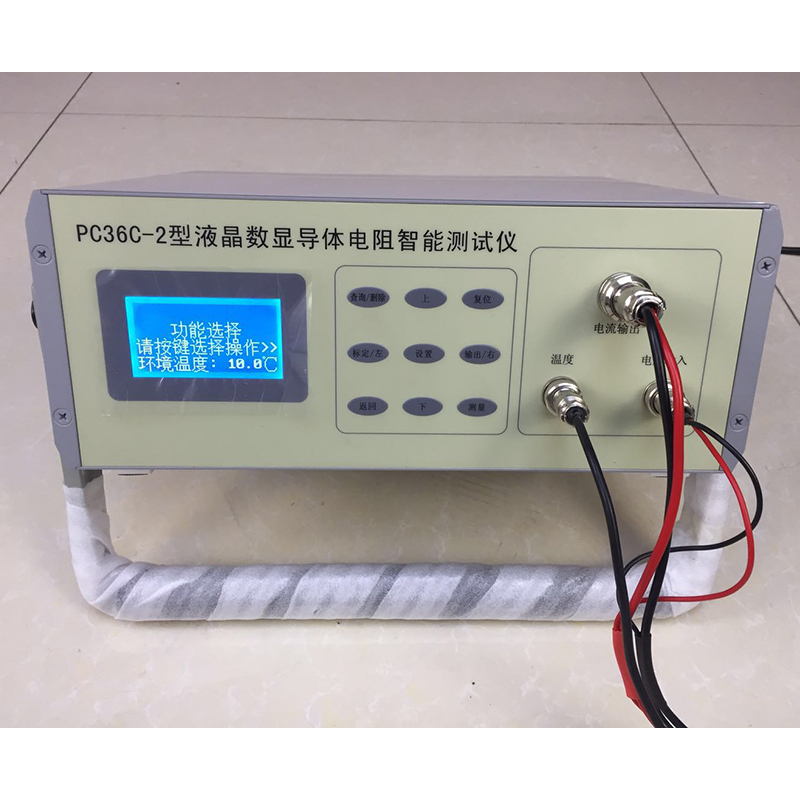

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy