Manufacturers of Cable Torsion Testing Equipment for Quality Assessment and Performance Evaluation

Cable Torsion Testing Machine Manufacturers A Comprehensive Overview

In the ever-evolving world of material testing, cable torsion testing machines play a pivotal role in the assessment of the torsional properties of cables and wires. These machines are essential for manufacturers and researchers who require reliable data on how cables behave under twisting forces. Understanding the significance of these machines, their manufacturers, and the technological innovations in the sector can provide valuable insights for businesses and professionals involved in the cable industry.

The Importance of Torsion Testing

Torsion testing is crucial for several applications where cables need to perform under rotational loads. These applications can range from aerospace, automotive, construction to telecommunications, where the durability and strength of cables can be the difference between a successful operation and catastrophic failure. By subjecting cables to controlled torsional forces, manufacturers can determine the maximum load a cable can sustain before failure, its elongation characteristics, and how it behaves under repetitive twisting.

Key Features of Cable Torsion Testing Machines

Manufacturers of cable torsion testing machines focus on a range of features that enhance the efficiency and accuracy of tests. These features typically include

1. Precision Load Cells High-quality load cells allow for precise measurements of the torque applied to the cable, ensuring that results are accurate and reliable.

2. Automated Control Systems Many modern machines are equipped with advanced automated systems that facilitate user-friendly operation. These systems might include programmable settings for different testing scenarios, allowing for quick adjustments based on the cable under testing.

3. Data Acquisition Systems Advanced data logging and monitoring systems capture real-time data during testing, ensuring that manufacturers can analyze performance metrics effectively.

4. Safety Features Given the potential hazards associated with high torque levels, manufacturers implement robust safety features, including emergency stop buttons, protective enclosures, and overload protection systems.

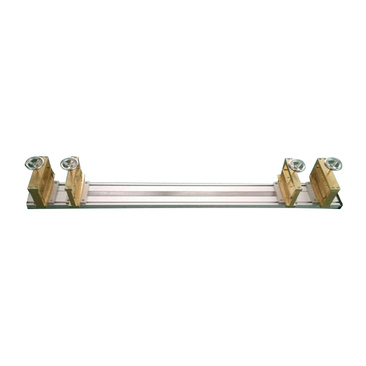

cable torsion testing machine manufacturers

The Leading Manufacturers

In the global market, several manufacturers have distinguished themselves by providing high-quality cable torsion testing machines. Notable names in this field often include

- Instron Renowned for its precision testing instruments, Instron offers a range of torsion testing machines tailored for different materials and testing requirements, ensuring high reliability and user-friendly operation.

- MTS Systems Corporation With a focus on advanced testing technologies, MTS provides torsion testing systems that are integrated with sophisticated data analysis software, aiding in research and development.

- ZwickRoell Known for its comprehensive testing solutions, ZwickRoell manufactures torsion testing machines that comply with international testing standards, catering to a wide array of industries.

- Shimadzu This company combines innovation with user needs, offering torsion testing devices that provide accurate and repeatable results, essential for quality control in manufacturing processes.

Technological Innovations

Technological advancements have significantly influenced the development of cable torsion testing machines. Innovations in materials science and engineering have led to the creation of machines that can conduct more refined tests with greater accuracy. Developments such as machine learning algorithms combined with data analytics are starting to revolutionize how torsion tests are conducted and interpreted.

Moreover, enhancements in automation have led to the creation of machines capable of performing simultaneous tests, increasing throughput and efficiency in test labs. Remote monitoring capabilities allow engineers to oversee tests in real-time, facilitating quicker decision-making and troubleshooting.

Conclusion

As the demand for high-quality, durable cables continues to rise across various sectors, the role of cable torsion testing machines becomes increasingly significant. Manufacturers who invest in advanced testing technology will not only enhance their product reliability but also ensure compliance with industry standards and customer expectations. Partnering with reputable manufacturers of cable torsion testing machines is crucial for any business looking to stay ahead in this competitive market. With a commitment to innovation and quality assurance, these manufacturers contribute greatly to the safety and efficiency of cable applications worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy