Suppliers of Cable Torsion Testing Equipment for Quality Assurance and Performance Evaluation

Exploring Cable Torsion Testing Machines Suppliers and Their Importance

In the realm of engineering and materials testing, the integrity and performance of cables are paramount. Whether used in construction, automotive, aerospace, or telecommunications, cables must endure various stresses and strains to ensure safety and reliability. One critical aspect of cable performance is its ability to withstand torsional forces. For this reason, cable torsion testing machines have become essential tools, enabling manufacturers and researchers to evaluate the torsional properties of cable materials. This article delves into the significance of these machines, the suppliers of cable torsion testing equipment, and the factors to consider when selecting a supplier.

Cable torsion testing machines are specifically designed to measure the twist resistance of various types of cables, ensuring they can perform effectively under operational conditions. By applying a controlled amount of torque and measuring the resulting angle of twist, engineers can assess a cable's durability and predict its behavior under real-world conditions. This testing is crucial for maintaining quality control in production processes and for research purposes in developing new materials or designs.

When it comes to sourcing cable torsion testing machines, there are several suppliers in the market, each offering a range of products tailored to different needs. It's essential to consider not just the machine itself but also the reputation and reliability of the supplier. Established suppliers often provide comprehensive solutions, including the machine, software for data analysis, and customer support, which can be invaluable for organizations that may not have extensive in-house expertise.

Key Considerations When Choosing a Supplier

1. Range of Products Different applications may require different specifications. A reputable supplier should offer a variety of machines capable of testing different cable types—such as fiber optic cables, power cables, and specialty wires—under various conditions.

2. Technical Support and Service After purchasing a testing machine, ongoing support is crucial. Look for suppliers that provide robust after-sales support, including technical assistance, maintenance services, and training for staff who will operate the machines.

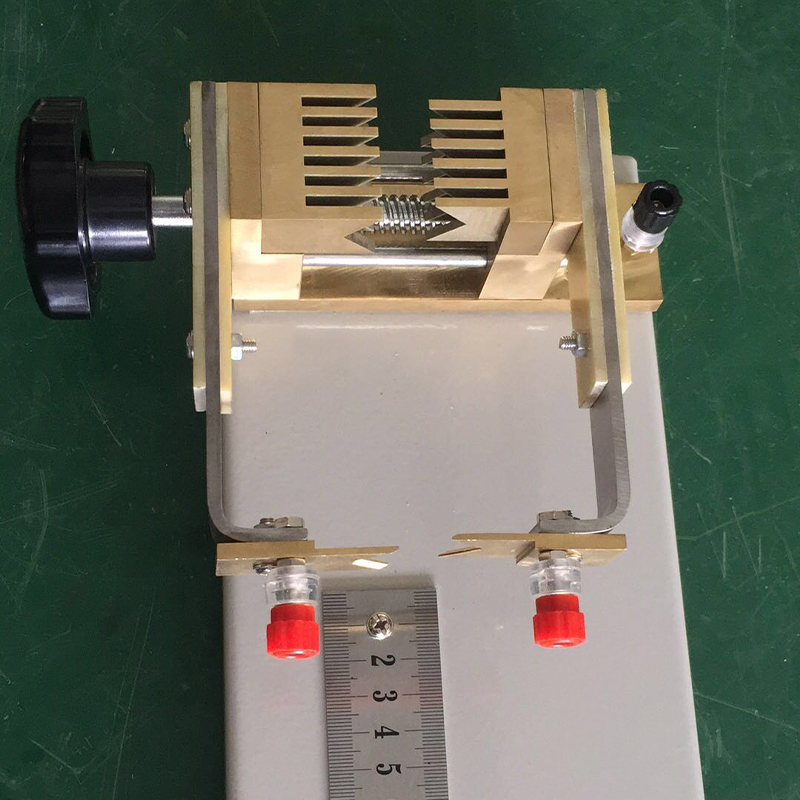

cable torsion testing machine supplier

3. Customization Options Each business has unique requirements based on the types of cables they produce or test. A good supplier will work with clients to develop customized solutions, adapting their machines to specific testing standards or procedures.

4. Quality and Standards Compliance Ensure that the supplier’s machines adhere to international testing standards, such as ASTM, ISO, or IEC. These certifications are signs of quality and reliability, ensuring that the testing process is recognized globally.

5. User-Friendly Technology Modern testing machines should be equipped with user-friendly interfaces, making it easy for operators to conduct tests and interpret results. Look for suppliers that incorporate advanced technology, such as automated data collection and reporting features.

6. Customer Reviews and References Researching customer feedback can provide insights into the supplier’s reputation. Positive reviews and testimonials from other companies within your industry can guide your decision.

Conclusion

In conclusion, cable torsion testing machines are indispensable tools for ensuring the quality and reliability of cables across various industries. As the demand for high-performance cables continues to grow, so does the importance of partnering with a trusted supplier. By considering key factors such as product range, technical support, customization, quality compliance, user-friendliness, and customer feedback, organizations can find a supplier that meets their specific needs. Investing in the right equipment and supplier not only enhances testing accuracy but also contributes significantly to the safety and effectiveness of cable products in the marketplace.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy