cable vertical flame test machine manufacturer

Understanding Cable Vertical Flame Test Machines A Manufacturer's Insight

In the realm of electrical safety, one of the pivotal assessments is the flame resistance of cables. This is where the cable vertical flame test machine plays a vital role. As a manufacturer in this specialized field, it's essential to understand the functions, importance, and design features of these machines that ensure cables meet international safety standards.

What is a Cable Vertical Flame Test Machine?

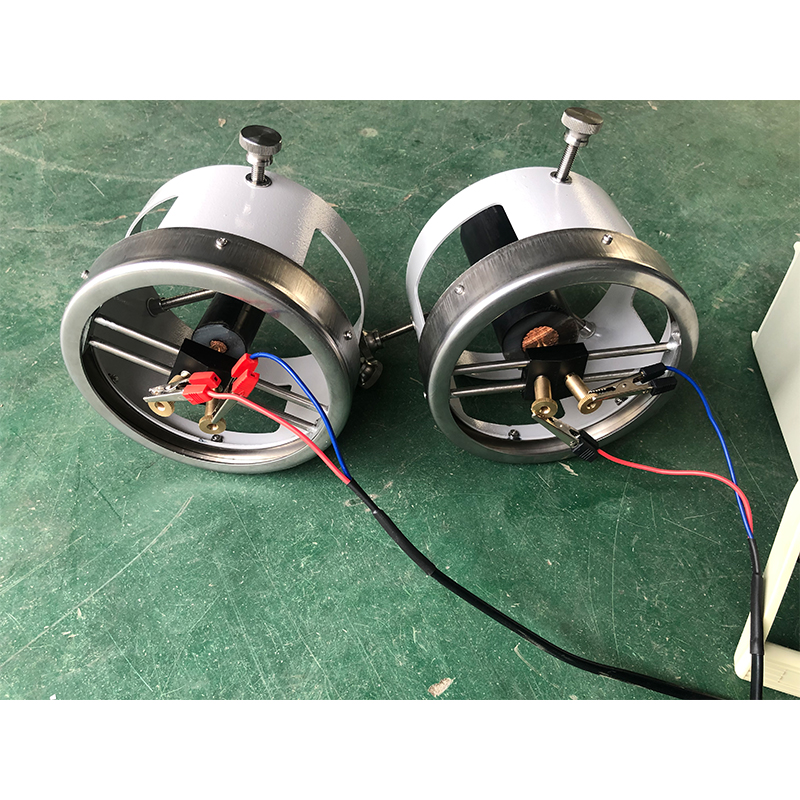

A cable vertical flame test machine is designed to evaluate the flammability and ignition resistance of various types of cables under controlled conditions. By exposing the sample cable to a flame for a specified duration, the machine measures important parameters such as the time to ignition, flame spread, and the duration of burning. This test is crucial for manufacturers and regulatory bodies to ascertain that cables can withstand fire exposure without contributing to the spread of flames.

Importance of Flame Testing

Flame testing is not merely a regulatory requirement but a fundamental aspect of ensuring safety in buildings, vehicles, and other environments where electrical cables are used. Poorly designed or manufactured cables can lead to catastrophic fires, resulting in loss of property and lives. By employing a vertical flame test machine, manufacturers can guarantee that their products adhere to safety standards such as the National Fire Protection Association (NFPA) guidelines and Underwriters Laboratories (UL) standards.

Key Features of a Quality Machine

When looking to invest in a cable vertical flame test machine, several features should be considered

cable vertical flame test machine manufacturer

1. Precision and Control A high-quality machine should allow for precise control over the flame's height and duration of exposure. This ensures that each test is conducted under consistent conditions.

2. Safety Mechanisms Given the nature of the testing, machines should come equipped with advanced safety features to protect operators from potential hazards associated with flame tests.

3. Data Analysis Capabilities Modern machines often include software for data logging and analysis, enabling manufacturers to track performance trends and make informed decisions based on testing outcomes.

4. Compliance with Standards Ensure that the machine complies with relevant international standards, as this will undoubtedly ease the certification process for the cables being tested.

5. Ease of Use The user interface should be intuitive, allowing operators to easily set parameters and interpret results without extensive training.

Conclusion

As a manufacturer of cable vertical flame test machines, understanding the nuances of flame resistance testing is paramount. By providing reliable, accurate, and safe testing solutions, manufacturers not only support their clients in complying with regulatory standards but also play a crucial role in enhancing electrical safety. Investing in state-of-the-art flame test machines ensures that cable products can withstand the rigors of real-world applications while protecting lives and property from fire hazards. In a world where safety cannot be compromised, the importance of testing and quality assurance cannot be overstated.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy