cable winding test machine manufacturer

The Importance of Cable Winding Test Machines in Manufacturing

In the ever-evolving world of manufacturing, the production of high-quality cables is paramount. The performance and reliability of cables can significantly affect various industries, from telecommunications to power distribution. To ensure cable quality, manufacturers increasingly rely on specialized equipment, one of which is the cable winding test machine. This article explores the role and significance of these machines in ensuring optimal cable performance.

A cable winding test machine is designed to simulate the conditions that cables will experience in real-world applications. By subjecting cables to various winding and unwinding processes, manufacturers can assess the mechanical and electrical properties of the cables. This testing is crucial for identifying weaknesses or defects that could lead to catastrophic failures in the field. The machine performs standardized tests, such as tensile strength, elongation, and temperature resistance, helping manufacturers adhere to industry standards and regulations.

One of the critical advantages of using a cable winding test machine is the ability to conduct tests with precision and efficiency. Automated systems reduce human error and variability, leading to more reliable results. These machines can simulate different winding scenarios, such as tight or loose coils, and assess how these configurations affect the cable's performance. By analyzing such data, manufacturers can refine their production processes, improving product quality and consistency.

cable winding test machine manufacturer

Additionally, cable winding test machines are essential for research and development. Cable manufacturers are continually innovating, developing new materials and designs to enhance cable performance. These machines enable R&D teams to test prototypes under controlled conditions, providing valuable insights into their performance before they hit the market. This capability not only saves time and costs associated with faulty designs but also fosters innovation within the industry.

Moreover, the growing emphasis on sustainability in manufacturing makes cable winding test machines increasingly relevant

. As manufacturers strive to produce environmentally friendly and energy-efficient products, these machines can facilitate the testing of new, eco-friendly materials. By assessing how these materials perform under various conditions, manufacturers can optimize designs that meet both performance and environmental standards.The market for cable winding test machines has expanded significantly, with numerous manufacturers offering a variety of models to suit different needs. When selecting a cable winding test machine, factors such as testing capabilities, automation level, and ease of use should be considered. Investing in high-quality testing equipment can enhance production efficiency and ensure that the final products meet the highest standards of quality and reliability.

In conclusion, cable winding test machines play a vital role in the manufacturing of high-quality cables. By enabling precise testing under simulated conditions, these machines help manufacturers identify potential issues and develop better products. As the demand for reliable and efficient cables continues to grow, the importance of investing in advanced testing equipment, like cable winding test machines, cannot be overstated. They are not just an investment in equipment; they are an investment in the future of cable manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

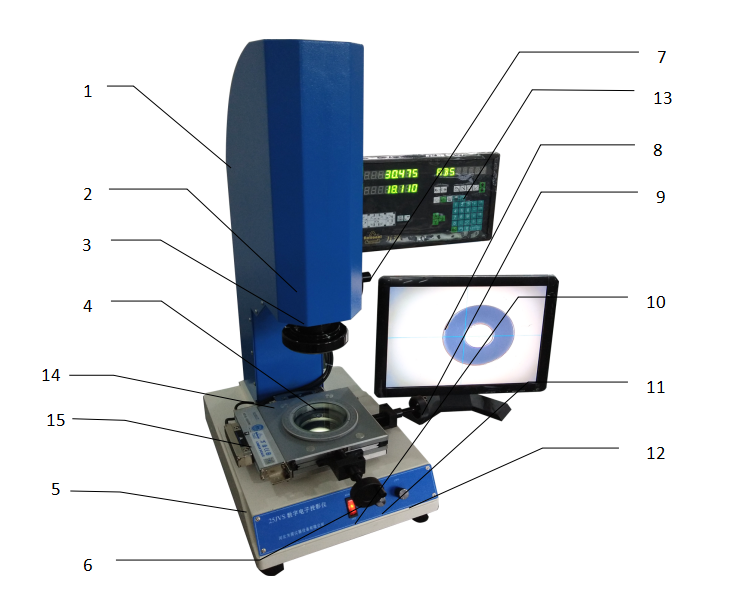

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy