Cable Winding Test Equipment Manufacturers and Their Key Offerings

Cable Winding Test Machine Suppliers A Comprehensive Guide

In the manufacturing and development of electrical cables, ensuring the integrity and performance of the products is essential. One of the key processes involved in this evaluation is the use of cable winding test machines. These specialized tools are designed to simulate real-world conditions that cables will face, allowing manufacturers to assess their durability, flexibility, and overall performance. For businesses involved in cable manufacturing, selecting the right suppliers of cable winding test machines is crucial. This article explores the importance of these machines, the factors to consider when choosing suppliers, and highlights some notable suppliers in the industry.

Importance of Cable Winding Test Machines

Cable winding test machines play a pivotal role in the quality control process of electrical cables. They are primarily used to perform winding tests, which involve wrapping cables around a drum under controlled conditions. This helps in determining the mechanical properties of the cable, such as its resistance to bending, twisting, and other forms of stress.

The results from these tests can provide valuable insights into product performance. For instance, a cable that fails a winding test may be prone to breakage or malfunction under real-world conditions, making it essential for manufacturers to identify such weaknesses early in the production process. Thus, investing in reliable and accurate cable winding test machines is vital for ensuring product reliability and customer satisfaction.

Key Factors When Choosing Suppliers

When selecting suppliers for cable winding test machines, several factors should be considered to ensure the best fit for your needs

1. Quality and Technology The technology used in the manufacturing of test machines greatly impacts their accuracy and performance. Look for suppliers that employ advanced technology and adhere to international quality standards. Read customer reviews and testimonials to gauge the performance of their machines.

2. Customization Different types of cables may require specific test parameters. A good supplier should offer customizable solutions tailored to your specific needs. This flexibility allows manufacturers to conduct tests that are relevant to their product lines.

3. Technical Support It is crucial to assess the level of after-sales service and technical support provided by the supplier. A reliable supplier should offer training on how to use the equipment, as well as ongoing technical assistance to troubleshoot any issues.

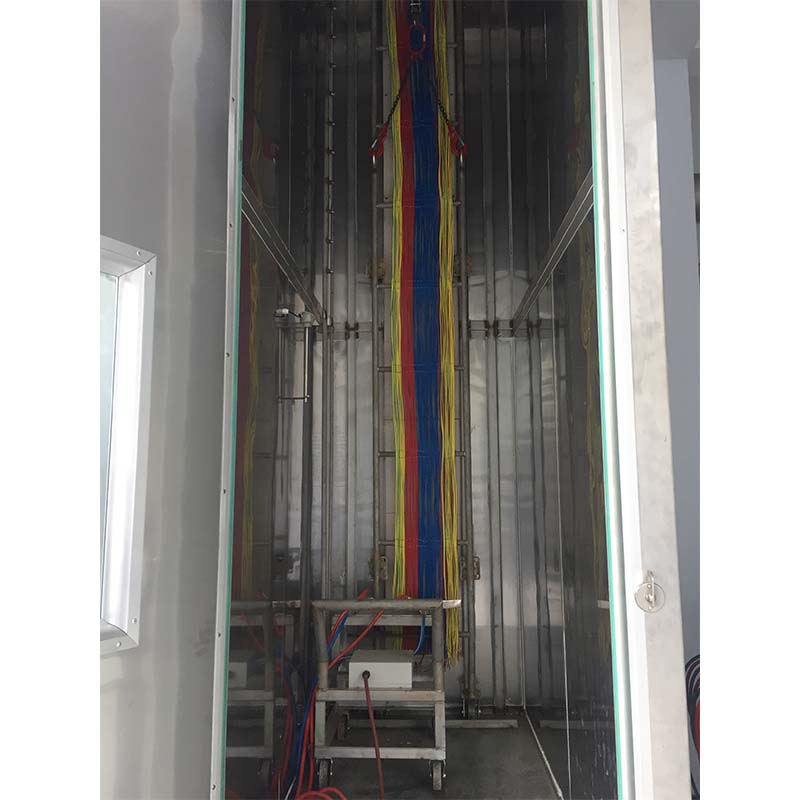

cable winding test machine suppliers

4. Pricing The cost of test machines can vary significantly between suppliers. While it is important to find a machine that fits your budget, this should not come at the expense of quality. Consider the long-term value of the investment and choose a supplier that offers competitive pricing without compromising on quality.

5. Reputation and Experience Choose suppliers with a solid reputation and extensive experience in the field. Established suppliers are more likely to offer reliable products and services due to their in-depth understanding of industry needs.

Notable Cable Winding Test Machine Suppliers

Several manufacturers stand out in the market for their high-quality cable winding test machines and excellent customer service

1. Cimteq Cimteq offers a range of test equipment, including cable winding test machines, with a focus on innovative technology and quality. They are known for their customization options and strong technical support.

2. Dahlgren Testing With decades of experience, Dahlgren provides advanced testing solutions tailored for the wire and cable industry. Their machines are designed for reliability and precision, making them a popular choice among manufacturers.

3. Kusakabe This supplier specializes in various testing equipment, including winding machines. They are known for their robust designs and exceptional durability, catering to both small and large manufacturers.

4. Electrotest Electrotest combines innovation with affordability, offering a range of testing machines that suit varying budgets without sacrificing quality. Their customer service is highly rated, providing support through every step of the purchasing process.

Conclusion

Investing in cable winding test machines is crucial for any manufacturer looking to ensure the quality and reliability of their products. By considering factors such as technology, customization, support, pricing, and supplier reputation, manufacturers can select the right suppliers to meet their needs. With reliable suppliers like Cimteq, Dahlgren Testing, Kusakabe, and Electrotest available in the market, companies have access to high-quality equipment that ensures their cables meet the necessary performance standards. This, in turn, leads to improved product quality, customer satisfaction, and a strong competitive edge in the industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy