Calibration Services for Insulation Resistance Tester Manufacturing Facilities

Calibrating Insulation Resistance Testers A Key Practice for Factories

In the realm of electrical engineering and maintenance, insulation resistance testers play a crucial role in ensuring the safety and effectiveness of electrical installations. These devices are essential for assessing the integrity of insulation in electrical systems and equipment. However, for these instruments to provide accurate and reliable measurements, regular calibration is necessary, specifically in factory settings where precision and consistency are paramount.

Understanding Insulation Resistance Testing

An insulation resistance tester measures the resistance offered by insulation materials in electrical equipment, helping to identify potential faults that could lead to equipment failure or safety hazards. By applying a known voltage to the insulation, these testers display the resulting resistance, often measured in megohms (MΩ). High resistance values indicate good insulation condition, while low values can signify deterioration or defects.

Importance of Calibration

Calibration is the process of verifying and adjusting the accuracy of measuring instruments. In the context of insulation resistance testers, calibration ensures that the readings are correct and reliable. This is particularly critical in industrial environments where equipment operates under demanding conditions and where even minor discrepancies can lead to significant consequences, including unplanned downtime, equipment damage, and safety risks.

Factory Calibration Practices

To maintain optimal performance, factories should establish regular calibration schedules for their insulation resistance testers. This involves using standardized procedures outlined by manufacturers or industry standards, ensuring that each tester is compared against a known reference standard. This process may involve a series of steps, including

calibrate insulation resistance tester factories

2. Reference Standards Utilize calibration standards that are traceable to national or international standards. These can include calibrated insulation resistance testers that provide known resistance values for comparison.

3. Testing Procedure Conduct tests at various resistance levels to verify the tester's accuracy across its entire measuring range. Document the results meticulously to ensure compliance and traceability.

4. Adjustment If the tester is found to be out of specification, adjustments must be made as per the manufacturer's guidelines. This can involve internal adjustments or repairs that require specialized technical expertise.

5. Documentation Maintain a calibration log that includes all calibration activities, results, adjustments made, and the next scheduled calibration date. This documentation is vital for compliance with safety regulations and industry standards.

Benefits of Regular Calibration

Investing time and resources in the calibration of insulation resistance testers yields significant benefits. Firstly, it enhances the safety of electrical systems by ensuring accurate fault detection and prevention of equipment failure. Secondly, regular calibration helps prolong the lifespan of electrical equipment by identifying insulation issues early, allowing for timely intervention. Lastly, maintaining reliable testing practices fosters trust and compliance within regulatory frameworks, which can be critical for operational licenses and certifications.

Conclusion

In conclusion, calibrating insulation resistance testers in factory settings is a fundamental practice that cannot be overlooked. Accurate measurements not only safeguard the integrity of electrical systems but also contribute to overall operational efficiency and safety. Factories that prioritize calibration will reap the rewards of enhanced performance, reduced risks, and greater peace of mind in their electrical operations. By establishing a robust calibration routine, businesses can ensure that their insulation resistance testers remain reliable tools in maintaining safe and efficient electrical systems.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

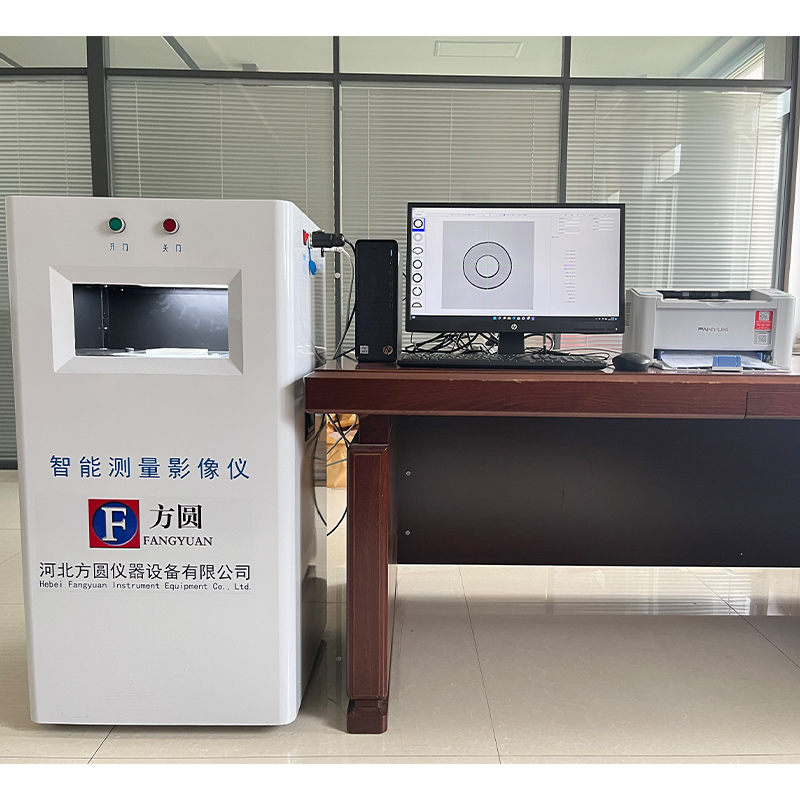

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy