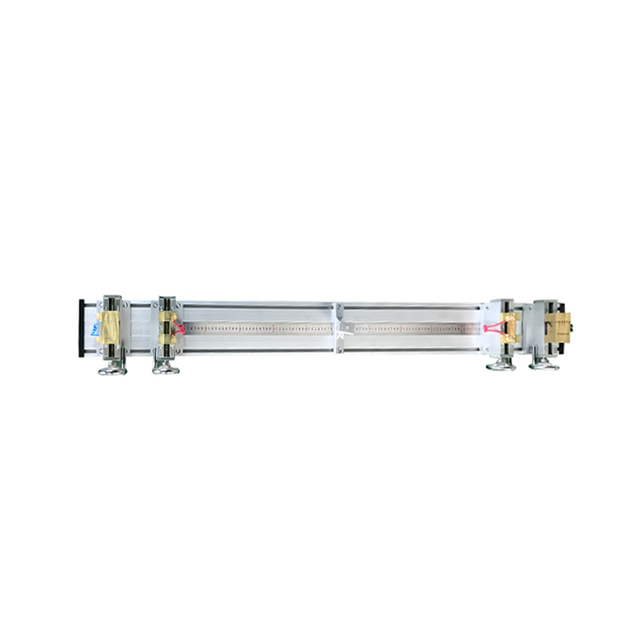

china cable cross-linked machine

Understanding the Cross-Linked Cable Production Machines in China

In recent years, the demand for high-performance cable products has surged, driven by advancements in technology and the rapid growth of industries such as telecommunications, electrical power, and automotive sectors. Central to meeting this demand is the cross-linked cable production machine, which has gained prominence in China due to its efficiency and effectiveness in manufacturing specialized cables. This article delves into the significance of these machines, their operational principles, and their impact on various industries.

What is a Cross-Linked Cable?

Cross-linked cables, often referred to as XLPE (cross-linked polyethylene) cables, are widely used for their superior thermal, electrical, and chemical properties. Unlike conventional cables, the cross-linking process enhances the material's strength and durability, making it suitable for high-voltage applications and harsh environmental conditions. This makes them ideal for power distribution, renewable energy systems, and industrial applications.

The Role of Cross-Linked Cable Machines

The production of cross-linked cables involves specialized machinery designed to facilitate the cross-linking process, which typically employs heat, chemicals, or radiation to create a three-dimensional molecular network within the cable material. In China, numerous manufacturers have invested in advanced technology to produce these machines, focusing on higher production speeds, improved quality control, and energy efficiency.

One of the key advantages of using a cross-linked cable machine is the ability to produce cables that comply with international standards. These machines are equipped with precision controls that allow manufacturers to monitor and adjust the production parameters in real-time, resulting in consistent and high-quality products.

Key Features of Chinese Cross-Linked Cable Machines

1. Automation and Control Systems Modern cross-linked cable machines are increasingly automated, incorporating advanced control systems that enable precise adjustments during the production process. This automation helps manufacturers achieve better consistency and reduces labor costs.

china cable cross-linked machine

2. Energy Efficiency With a growing emphasis on sustainability, many manufacturers are now focusing on energy-efficient designs for their machines. These innovations not only reduce operational costs but also minimize the environmental impact of cable production.

3. Versatility Chinese manufacturers have developed machines capable of producing a variety of cable types, including low-voltage, medium-voltage, and high-voltage cables. This versatility is crucial for meeting the diverse needs of different industries.

4. Customized Solutions Many Chinese companies offer tailor-made solutions, allowing clients to modify machines according to their specific production requirements. This flexibility enhances customer satisfaction and loyalty.

Impact on the Industry

The proliferation of cross-linked cable production machines in China has significantly impacted both the domestic and global cable markets. With faster production cycles and lower costs, Chinese manufacturers have been able to offer competitive pricing, thereby increasing their market share internationally.

Moreover, the emphasis on quality and compliance with global standards has allowed Chinese manufacturers to penetrate markets that were previously dominated by established players from Europe and North America. This shift not only benefits consumers through lower prices but also encourages competition, fostering innovation in production processes and technology.

Conclusion

In conclusion, cross-linked cable machines play a vital role in the manufacturing of high-quality cable products, meeting the increasing demands of various industries. China's investment in advanced production technologies has positioned it as a key player in the global cable market. As industries continue to evolve, the efficiency and innovation offered by these machines will undoubtedly shape the future of cable manufacturing, ensuring that the requirements for high-performance electrical solutions are met effectively and sustainably.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy