china cable cut machine

The Importance of Cable Cutting Machines in Modern Manufacturing

In the fast-paced world of manufacturing and telecommunications, efficiency and precision are paramount. One crucial tool that has revolutionized the way cables are processed is the cable cutting machine. With the rise of technology and increasing demand for high-quality cables, these machines have become indispensable in ensuring that cables are not only cut accurately but also produced quickly and safely. This article will explore the significance of cable cutting machines, their functionality, and their impact on the industry, particularly in the context of China.

Cable cutting machines are designed to automate the process of cutting cables to specific lengths. Traditional methods of cable cutting often involve manual work, which can be time-consuming and prone to human error. However, automated cable cutting machines streamline this process by employing advanced mechanisms that ensure precision and consistency. This not only enhances productivity but also significantly reduces the likelihood of mistakes, leading to better overall quality in the final product.

The Importance of Cable Cutting Machines in Modern Manufacturing

One of the most significant advantages of modern cable cutting machines is their versatility. Many machines can be programmed to cut various types of cables, including power cables, data cables, and specialty cables. This adaptability is essential for manufacturers who need to cater to diverse client needs and rapidly changing market demands. Furthermore, advanced cable cutting machines are equipped with features such as length measurement, automatic feeding systems, and the ability to handle different materials, making them suitable for a wide range of applications.

china cable cut machine

In addition to efficiency and precision, cable cutting machines also contribute to safety in the workplace. Manual cutting methods often involve the use of sharp tools, which can pose a risk of injury. Automated machines eliminate much of this risk by allowing operators to control the equipment from a safe distance, minimizing direct contact with cutting tools. Additionally, advanced models come with safety features and fail-safes that help protect workers, further enhancing the overall safety of manufacturing environments.

Moreover, as industries worldwide push for greener processes, automated cable cutting machines can be integrated with more sustainable practices. Many new models are designed to minimize waste, ensuring that the maximum amount of material from each reel of cable is utilized. This not only aligns with global sustainability goals but also reduces costs for manufacturers. In China, where environmental regulations are becoming stricter, the adoption of such machines supports compliance with these laws.

Despite the many advantages, the initial investment in automated cable cutting machines can be significant. However, manufacturers must view this as a long-term investment that pays off through increased efficiency, reduced labor costs, and higher output quality. In a highly competitive market, being able to produce high-quality cables at a competitive price is crucial for maintaining market share.

In conclusion, cable cutting machines represent a vital component of modern manufacturing, particularly in the cable production industry. With their precise cutting capabilities, safety features, and adaptability, these machines enable manufacturers, especially in a leading production hub like China, to meet the growing demands of a rapidly evolving market. As technology continues to advance, the role of cable cutting machines will undoubtedly expand, further enhancing productivity and quality in the manufacturing sector.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

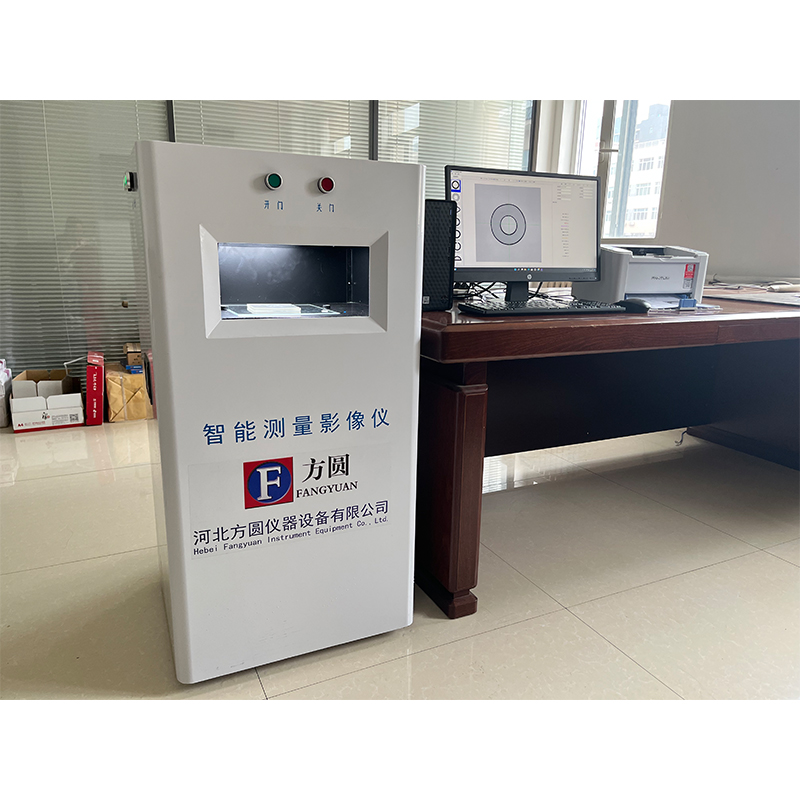

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy