china cable repeated bending tester

Understanding the China Cable Repeated Bending Tester A Key Tool for Cable Quality Assessment

In today's technology-driven world, the performance and reliability of electrical cables are paramount, especially in sectors such as telecommunications, automotive, and consumer electronics. To ensure that cables can withstand repeated stresses during installation and usage, manufacturers utilize testing equipment like the China Cable Repeated Bending Tester. This innovative device plays a crucial role in evaluating cable durability, flexibility, and overall mechanical performance.

What is a Cable Repeated Bending Tester?

A Cable Repeated Bending Tester is a specialized piece of equipment designed to simulate the repetitive bending and flexing that cables experience in real-world applications. The tester subjects samples to a predefined number of bending cycles, assessing how well they maintain their integrity under stress. This process is essential for determining the endurance of cables in various conditions, such as constant movement, vibration, or extreme temperatures.

Key Features and Functionality

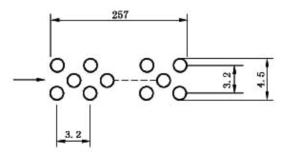

The China Cable Repeated Bending Tester typically includes several key components a programmable control system, bending fixtures, and mechanical testing sensors. The programmable control system allows for the customization of testing parameters, such as the angle and radius of curvature, as well as the speed of bending. This flexibility enables manufacturers to replicate the specific conditions that their cables will encounter in real-life scenarios.

Bending fixtures hold the cable in place and ensure accurate and consistent testing across each sample. The mechanical sensors monitor the cable’s response to repeated bending, recording data on any structural changes, including the development of cracks, breakages, or insulation failures. This data is invaluable for understanding the long-term reliability of the cables being tested.

china cable repeated bending tester

Benefits of Using a Repeated Bending Tester

Conducting repeated bending tests provides numerous benefits for manufacturers. Firstly, it allows for a comprehensive assessment of the cable's performance over time. By identifying weaknesses before cables reach the market, manufacturers can make necessary design modifications to improve durability and minimize the risk of failure.

Secondly, this testing equipment helps ensure compliance with international standards and regulations. Many industries have specific quality standards that cables must meet. By using a Repeated Bending Tester, manufacturers can produce documentation and evidence of testing results, demonstrating their commitment to quality and safety.

Lastly, utilizing such testing equipment can lead to enhanced customer satisfaction. Reliable, durable cables reduce the likelihood of replacements and repairs, contributing to a better user experience. In competitive markets, having high-quality cables can also be a significant differentiator.

Conclusion

As the demand for high-quality electrical cables increases, the importance of rigorous testing methods cannot be overstated. The China Cable Repeated Bending Tester provides an effective solution for manufacturers seeking to ensure their products are reliable and compliant with industry standards. By simulating real-world bending conditions, this testing equipment helps identify potential vulnerabilities, ultimately leading to the development of more durable cables.

In an era where technology is constantly evolving, the need for robust testing solutions is greater than ever. Investing in the China Cable Repeated Bending Tester is not just about meeting standards; it’s about setting them. By prioritizing quality in cable manufacturing, companies can remain competitive and provide their customers with products they can trust, thereby reinforcing their reputation in the market. With this testing technology, the future of cable manufacturing is looking more resilient than ever.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy