Testing Equipment for Vertical Flame Resistance in Chinese Cable Products

Understanding the China Cable Vertical Flame Test Machine

In recent years, the importance of safety standards in cable manufacturing has escalated, driven by rising concerns over fire hazards associated with electrical installations. One of the most critical tools deployed in ensuring cable materials meet stringent safety requirements is the Vertical Flame Test Machine. In this article, we will explore the purpose, functioning, and significance of the China Cable Vertical Flame Test Machine in the context of improving fire safety in electrical cables.

Purpose of the Vertical Flame Test Machine

The primary objective of the Vertical Flame Test Machine is to evaluate the flammability characteristics of various cable materials under standardized conditions. This testing apparatus helps manufacturers and regulatory bodies ascertain whether the cables can resist ignition and what their behavior would be in the event of a fire. Utilizing this machine, cables are subjected to a controlled flame application, allowing testers to gather crucial data on their flame spread rate, drippings, smoke production, and burning duration. The results of these tests are essential for compliance with international safety standards such as IEC, UL, and NFPA.

Functioning of the Machine

A typical Vertical Flame Test Machine consists of several key components a combustion chamber, a flame source, and measurement devices. The machine is designed to accommodate cables of various sizes and materials. During testing, the cable sample is mounted vertically, and an open flame is applied to the bottom portion of the cable for a predetermined duration, usually around 15 seconds.

The following are the critical steps involved in the testing process

1. Sample Preparation Cable samples are prepared according to specific dimensions and conditions as specified by the standards in question. This ensures that the test results are comparable and reliable.

2. Flame Application The flame source is ignited and positioned at the bottom of the vertically held cable sample. The duration of exposure to the flame and the flame height is meticulously controlled.

china cable vertical flame test machine

3. Observation and Measurement Observations are made regarding the ignition of the sample, the time it takes for flames to spread along the length of the cable, and whether any drippings occur that could potentially ignite surrounding materials.

4. Data Recording Various measurements are recorded, such as the time taken for ignition, burning time, and whether the cable continues to burn after the flame is removed. Additional factors such as smoke density and toxic gas emissions may also be measured, as they are critical to understanding a material's safety profile.

Significance of the Test Machine

The significance of the China Cable Vertical Flame Test Machine cannot be overstated. As cities grow and electrical infrastructures expand, the requirement for fire-resistant materials becomes even more pressing. Cables are often run through walls, ceilings, and conduits, meaning that their failure in the event of a fire could lead to rapid fire spread and increased risks to human life and property.

The data generated by this testing machine supports product development, ensuring that newly designed cables can bear fire exposure without contributing to the spread of flames. It also enhances consumer confidence, as manufacturers can claim compliance with higher safety standards, therefore mitigating risk and liability.

Moreover, regulatory bodies often require testing and certification, making the Vertical Flame Test Machine an indispensable asset for manufacturers aiming to enter both domestic and international markets.

Conclusion

The China Cable Vertical Flame Test Machine is a critical tool in the quest for electrical safety. By rigorously testing the flammability of cable materials, manufacturers can ensure their products meet vital safety standards, thereby minimizing fire hazards and protecting lives and property. As the demand for safe electrical solutions continues to rise, the role of such testing equipment becomes ever more critical in the electrical manufacturing industry. Investing in advanced testing machinery not only fosters innovation but also aligns with the growing global emphasis on safety and sustainability.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

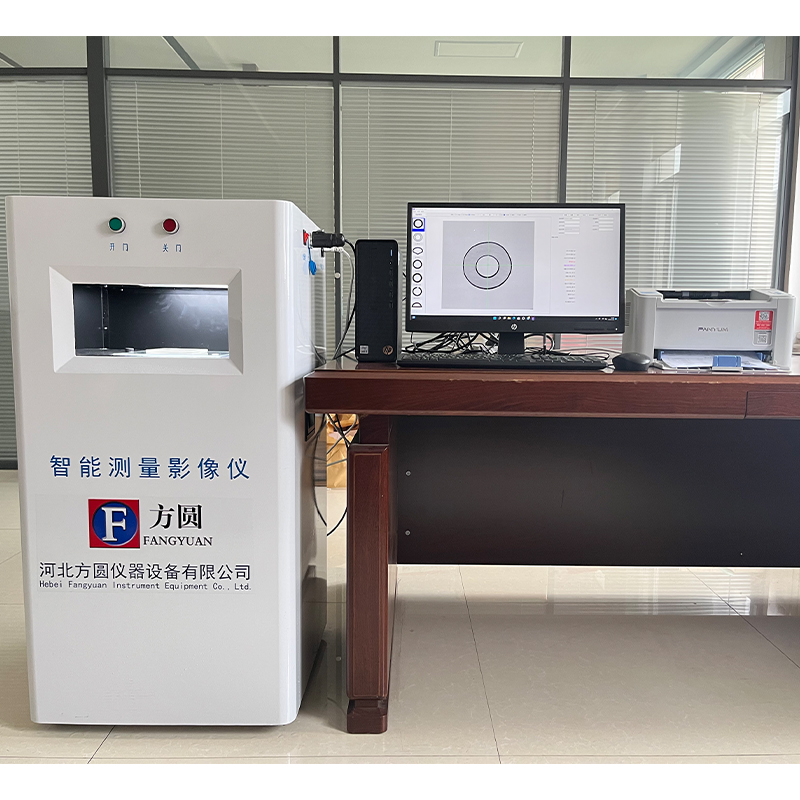

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy