Innovative Optical Profile Projectors for Precision Measurement in China's Digital Industry

Exploring the World of Optical Profile Projectors in China

In recent years, China's manufacturing sector has undergone a significant transformation, leveraging advanced technologies to enhance precision and efficiency in production processes. Among these innovations, optical profile projectors have emerged as a critical tool for quality control and measurement in various industries, including automotive, aerospace, electronics, and precision machinery. This article delves into the role and advancements of digital optical profile projectors in China, illustrating their applications, benefits, and potential future developments.

Optical profile projectors, also known as shadowgraphs, are precision instruments that project the silhouette of a part onto a screen, allowing operators to inspect dimensions and contours accurately. The integration of digital technology into these devices has revolutionized the traditional methods of measurement. Digital optical profile projectors provide enhanced accuracy and ease of use compared to their analog predecessors. They feature advanced imaging systems, typically equipped with high-resolution cameras and sophisticated software for data analysis.

In China, the adoption of digital optical profile projectors has been accelerated by the urgent need for quality assurance in manufacturing. As the country continues to emphasize high-quality production, industries are increasingly turning to these tools to ensure that all components meet stringent specifications. The ability to measure complex geometries and enforce tight tolerances has made these projectors indispensable in competitive manufacturing environments.

The benefits of using digital optical profile projectors extend beyond mere measurement. Firstly, they streamline the inspection process, significantly reducing the time required to evaluate parts. This efficiency is crucial for manufacturers who aim to minimize cycle times and optimize workflows. Secondly, the digital nature of these projectors allows for easier data storage and retrieval, enabling companies to maintain comprehensive quality records over time, which is essential for compliance and audits.

Moreover, the software accompanying digital optical profile projectors offers advanced features such as automatic edge detection, contour mapping, and statistical process control. These capabilities allow operators to make real-time decisions based on precise measurement data. In today's data-driven manufacturing landscape, the ability to analyze and respond to production metrics swiftly gives companies a competitive edge.

china digital optical profile projectors

Another notable development in China's optical profile projector market is the rise of local manufacturers. Traditionally, many high-precision instruments were imported from established brands in Europe and North America. However, as local companies invest in research and development, they have begun producing competitive profiling projectors that meet international standards. This shift not only reduces dependency on foreign technology but also fosters innovation within the Chinese manufacturing ecosystem.

China's commitment to industry 4.0 and smart manufacturing has further propelled the evolution of optical profile projectors. With the integration of IoT (Internet of Things) technologies, modern projectors can be connected to centralized monitoring systems, facilitating seamless data exchange across production lines. Such interconnectedness enables predictive maintenance, helping manufacturers avoid costly downtimes associated with equipment failures.

Looking ahead, the future of digital optical profile projectors in China appears bright. As industries continue to embrace automation and smart technologies, these measuring instruments will likely become even more sophisticated. Features like AI-powered image recognition and machine learning algorithms could enhance measurement capabilities, enabling automated inspections and real-time adjustments during the manufacturing process.

Additionally, as environmental standards grow stricter, the demand for sustainable practices in manufacturing will be more critical than ever. Digital optical profile projectors, with their ability to reduce waste through precise measurements, will play a vital role in helping manufacturers achieve their sustainability goals.

In conclusion, digital optical profile projectors are reshaping the measurement landscape in China, providing manufacturers with the tools needed to ensure quality and precision in their processes. As technology advances and local innovations emerge, the role of these instruments in maintaining competitive advantage will only continue to grow, solidifying their place as essential components in China's manufacturing future.

-

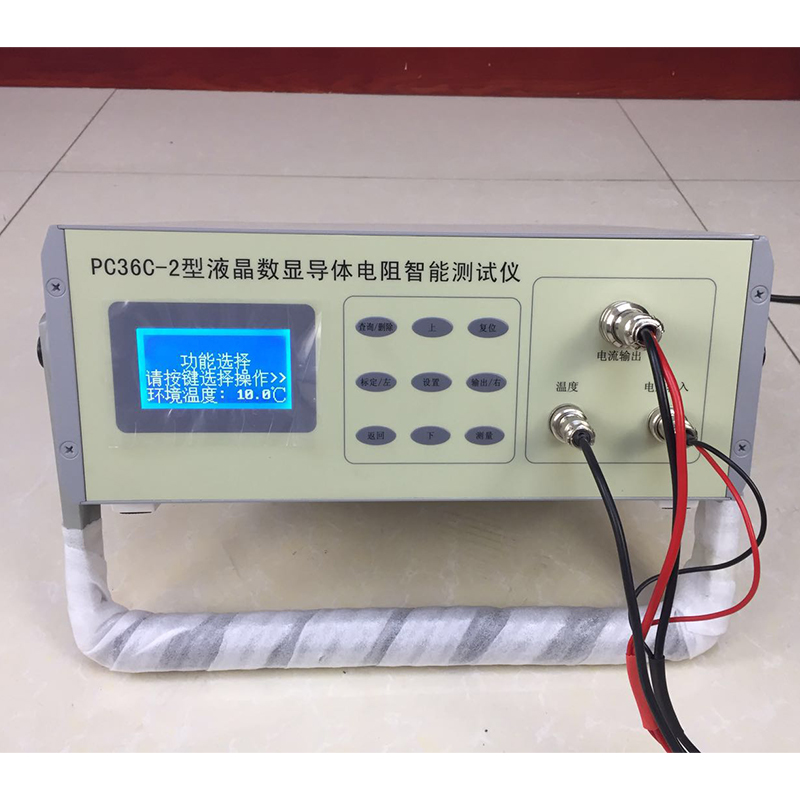

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy