china electromechanical universal tensile tester

Understanding the China Electromechanical Universal Tensile Tester A Key Tool for Material Testing

Introduction

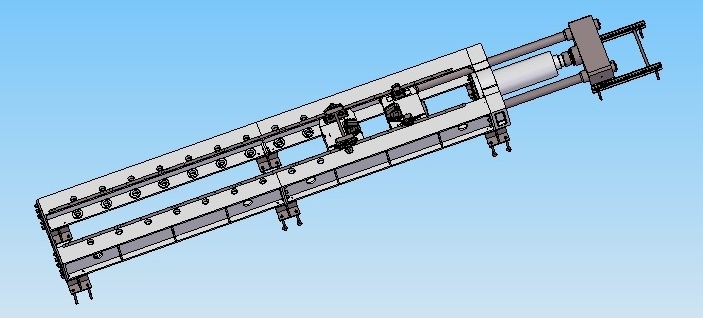

In the realm of material testing, the China Electromechanical Universal Tensile Tester stands out as a vital instrument used across various industries for assessing the tensile strength, elongation, and other mechanical properties of materials. This device is engineered to provide accurate and reliable results, ensuring that manufacturers and researchers can maintain high standards of quality and safety in their products. This article delves into the features, applications, and significance of this testing machine in both industrial and research settings.

What is a Universal Tensile Tester?

A universal tensile tester is a type of testing equipment used to measure the mechanical properties of materials under tension. It works by applying a controlled tensile force to a material specimen and measuring how the material deforms until it ultimately fractures. The fundamental properties assessed during the testing process include tensile strength, yield strength, elastic modulus, and percentage elongation.

China's Contribution to Material Testing Equipment

China has become a global leader in manufacturing electromechanical testing equipment due to its technological advancements, cost efficiency, and commitment to quality. The China Electromechanical Universal Tensile Tester is an exemplary product of this growth, designed to meet international standards while providing an affordable solution for various testing needs.

Key Features of the China Electromechanical Universal Tensile Tester

1. High Precision One of the defining characteristics of this machine is its precision. The use of advanced sensors and control systems allows for accurate measurements, enabling users to obtain reliable data for quality control and research.

china electromechanical universal tensile tester

2. Wide Testing Range These testers can accommodate a diverse range of materials, including metals, plastics, rubber, and composites, making them versatile tools in both laboratories and production environments.

3. User-Friendly Interface Modern tensile testers come equipped with intuitive software that simplifies the testing process. Users can easily set parameters, monitor tests in real-time, and review results through comprehensive reports.

4. Safety Features Safety is paramount in material testing. The design of the China Electromechanical Universal Tensile Tester incorporates various safety mechanisms, including overload protection and automatic shut-off features, to ensure safe operation.

5. Robust Construction Built from high-quality materials, these testers are designed for durability and reliability, capable of withstanding the rigors of frequent use in industrial settings.

Applications of the Universal Tensile Tester

The applications of the China Electromechanical Universal Tensile Tester are broad and impactful. In the automotive industry, it is used to test the tensile strength of metal components to ensure safety and durability in vehicles. In the aerospace sector, it assesses materials used in aircraft to validate performance under extreme conditions. Additionally, the biomedical field utilizes these testers to evaluate the mechanical properties of materials used in medical devices and implants.

Moreover, the building and construction industry employs tensile testers to measure the strength of various materials, such as concrete and steel, ensuring they meet required specifications for safety and performance.

Conclusion

The China Electromechanical Universal Tensile Tester represents a significant advancement in material testing technology. Its high precision, versatility, and user-friendly features make it an indispensable tool for various industries, where material integrity is crucial. As manufacturers continue to invest in technology to enhance quality control and compliance with global standards, the importance of reliable testing equipment like the electromechanical universal tensile tester cannot be overstated. This machine not only contributes to the improvement of product quality but also plays a pivotal role in ensuring safety and reliability in a wide range of applications. Embracing such technology is essential for industries aiming to thrive in today’s competitive marketplace.

-

Reliable CHJ Series Spark Tester for Insulation Quality Control

NewsSep.01,2025

-

QNJ-2/3 Cable Flexibility Test Machine: Precision & Durability

NewsAug.31,2025

-

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy