China Fabric Tensile Strength Testing Machine for Quality Evaluation and Performance Analysis

Exploring the Role of Tensile Strength Testers in China's Fabric Industry

In the rapidly evolving landscape of the textile industry, ensuring quality and durability is paramount. One of the key instruments that manufacturers and researchers in China rely on is the fabric tensile strength tester. This essential tool plays a pivotal role in assessing the mechanical properties of textiles, providing crucial data that influences production methods, material selection, and product safety.

Tensile strength refers to the maximum amount of tensile (stretching) stress that a material can withstand before failure. In the context of fabrics, it determines how much force a fabric can endure when subjected to stretching and tension before breaking. As China continues to be a global leader in textile production, the importance of accurate tensile strength testing cannot be overstated. It not only helps manufacturers ensure that the fabrics meet international standards but also supports the development of innovative textile materials with superior performance.

The process of tensile strength testing involves gripping a specimen of the fabric and gradually applying a load until the material fails. This method allows for the determination of both the ultimate tensile strength (the maximum stress the material can bear) and the elongation at break (the extent to which the fabric can stretch before breaking). The data obtained from these tests is essential for various applications, including apparel, home textiles, and industrial fabrics.

In recent years, the demand for high-quality textiles has surged, driven by changing consumer preferences and technological advancements. As a result, the fabric tensile strength tester has become more sophisticated, with many modern devices incorporating digital interfaces, automated features, and advanced data analysis capabilities. These enhancements allow for more precise measurements and easier data interpretation, enabling manufacturers to make informed decisions quickly.

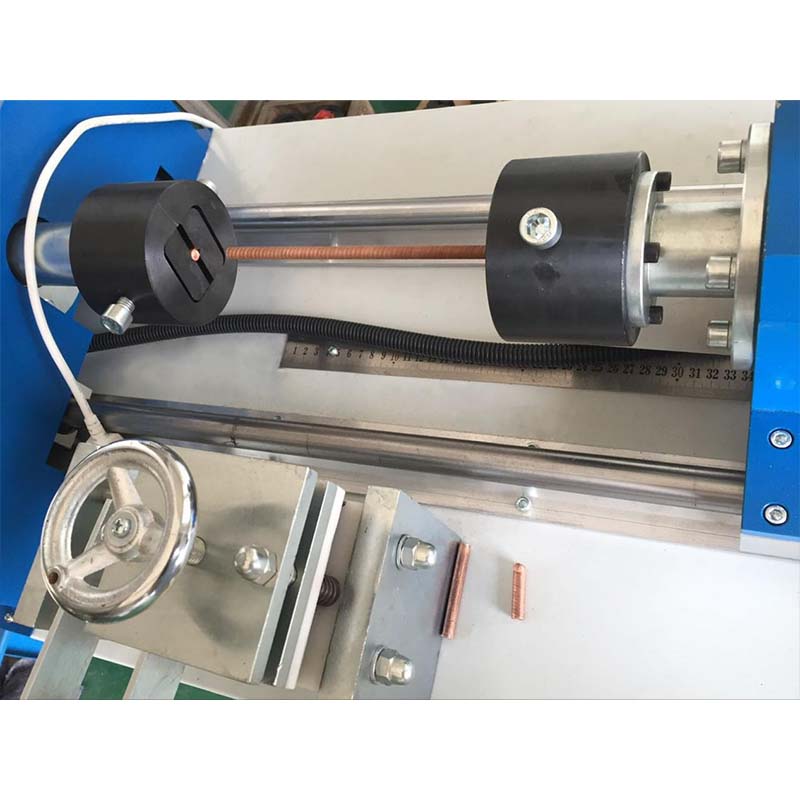

china fabric tensile strength tester

Moreover, with the rise of sustainability and environmental consciousness among consumers, the textile industry is placing greater emphasis on the durability of materials. Fabrics that can withstand wear and tear are not only more desirable but also contribute to reducing waste by prolonging the lifespan of garments and other textile products. By incorporating tensile strength testing into their quality control processes, manufacturers can enhance the longevity of their fabrics and appeal to eco-conscious consumers.

In addition to supporting product quality, tensile strength testing also plays a critical role in meeting regulatory standards. Many countries have specific requirements regarding the mechanical properties of textiles, particularly for items such as safety gear and protective clothing. By employing fabric tensile strength testers, Chinese manufacturers can ensure compliance with both domestic and international regulations, facilitating smoother access to global markets.

Furthermore, the continuous development of testing technologies is helping to shape the future of the fabric industry in China. With the integration of machine learning and artificial intelligence, data analysis during tensile strength testing is becoming more sophisticated. These advancements enable manufacturers to predict fabric performance based on various parameters, leading to the design of smarter, more resilient textiles.

In conclusion, the fabric tensile strength tester is a vital instrument in China's thriving textile industry. It plays a significant role in ensuring product quality, supporting sustainability, and meeting regulatory requirements. As technology evolves, the capabilities of these testing devices will continue to enhance, allowing for even greater precision and efficiency in fabric evaluation. The impact of these advancements will resonate throughout the entire supply chain, ultimately benefiting consumers and manufacturers alike.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy