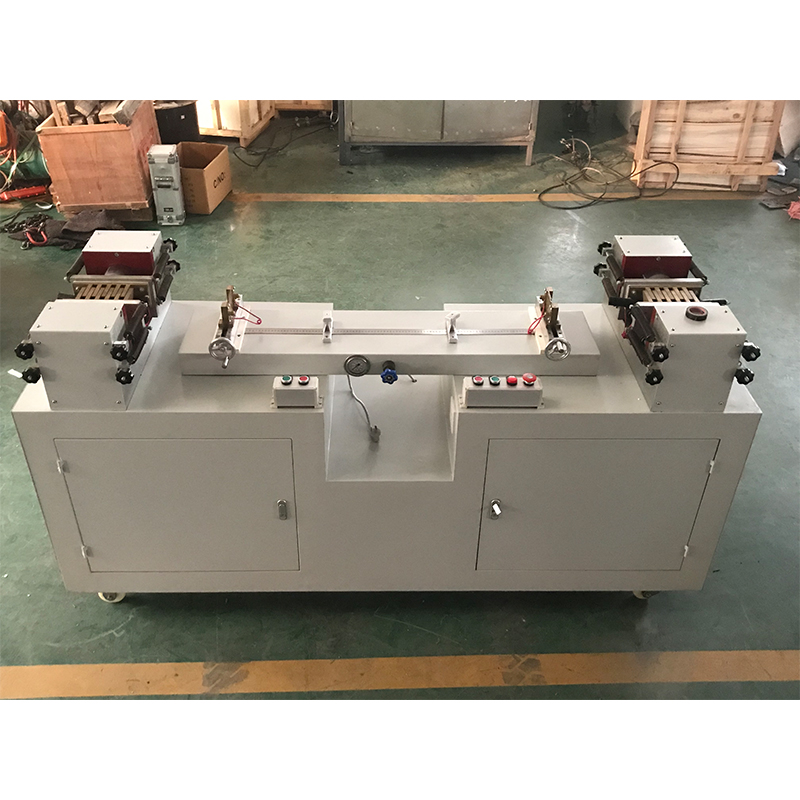

China Fabric Tensile Strength Testing Equipment for Quality Assurance in Textile Industry

The Importance of Tensile Strength Testing in the Fabric Industry

In the textile industry, the investigation of fabric properties is crucial for ensuring quality and performance. One of the key tests conducted is the tensile strength test, a process that measures the force required to pull a material until it breaks. This test is essential for manufacturers and designers alike, especially in a country like China, which is a global leader in fabric production.

The Importance of Tensile Strength Testing in the Fabric Industry

China's fabric tensile strength testers have evolved considerably, incorporating advanced technologies that enhance accuracy and efficiency. Modern testing machines utilize sophisticated software and sensors that precisely measure the force applied to the fabric and the elongation until it breaks. This level of detail allows for comprehensive analysis and comparative studies across different fabric types, leading to informed choices in material selection.

china fabric tensile strength tester

Additionally, tensile strength testing is not only essential for evaluating new fabrics but also for quality control during production. Regular testing helps to mitigate risks associated with material defects and ensures that the fabrics produced adhere to both domestic and international standards. Compliance with these standards is particularly important for export-oriented businesses in China, as it affects market access and consumer trust.

Furthermore, the knowledge gained from tensile strength tests can guide modifications in fabric design and manufacturing processes. Manufacturers can experiment with different blends and finishes to optimize performance characteristics, such as strength, elasticity, and resistance to wear. This innovative approach contributes to the development of new fabric technologies that meet the evolving demands of consumers and industries.

In conclusion, tensile strength testing is a critical component in the fabric industry, particularly in China, where the textile sector plays a significant role in the economy. By utilizing advanced testing methods, manufacturers can ensure quality, adhere to safety standards, and ultimately deliver superior products. As the industry continues to grow, the importance of such testing will only increase, driving innovations that benefit both producers and consumers alike.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy