Testing Equipment for Flexible Cables in China Industry Standards and Practices

Testing Equipment for Flexible Cables in China

In recent years, the demand for high-quality flexible cables has surged in China as industries increasingly rely on advanced electrical and electronic systems. Flexible cables, characterized by their adaptability and maneuverability, are essential for various applications ranging from telecommunications to automotive and renewable energy sectors. To ensure the reliability and safety of these flexible cables, rigorous testing is paramount. This article delves into the testing equipment used in China to evaluate the performance and integrity of flexible cables, underscoring its significance in maintaining industry standards.

Importance of Testing Flexible Cables

Flexible cables must withstand diverse operating conditions, including bending, twisting, and exposure to various environmental stresses. Testing these cables helps identify potential weaknesses, prevents failures, and enhances overall safety. Moreover, as regulatory standards become more stringent, manufacturers must demonstrate compliance through systematic testing, which is where specialized testing equipment comes into play.

Types of Testing Equipment

1. Insulation Resistance Testers Insulation resistance testers are crucial for assessing the insulation quality of flexible cables. These devices apply a high voltage to the cable and measure the resistance, ensuring it meets safety standards. In China, these testers are available in several configurations, catering to different voltage ranges and applications.

2. Continuity Testers Continuity testing is fundamental in ensuring that electrical connections within the cable are intact. Continuity testers check if there is a complete path for current flow, which is vital for the cable's performance. Automated continuity testers have gained popularity in China's manufacturing sector due to their precision and speed.

3. Cable Fault Locators Flexible cables can develop faults over time, often invisible to the naked eye. Cable fault locators utilize advanced technology to detect and pinpoint faults in the cable, preventing costly downtimes. These devices are essential for utilities and service providers that need to maintain extensive cable networks.

china flexible cables testing equipment

4. Environmental Test Chambers These chambers simulate various environmental conditions, including extreme temperatures, humidity, and mechanical stress. Flexible cables are subjected to these conditions to evaluate their performance and durability over time. In China's competitive market, manufacturers often employ such chambers to ensure their products can withstand rigorous operational environments.

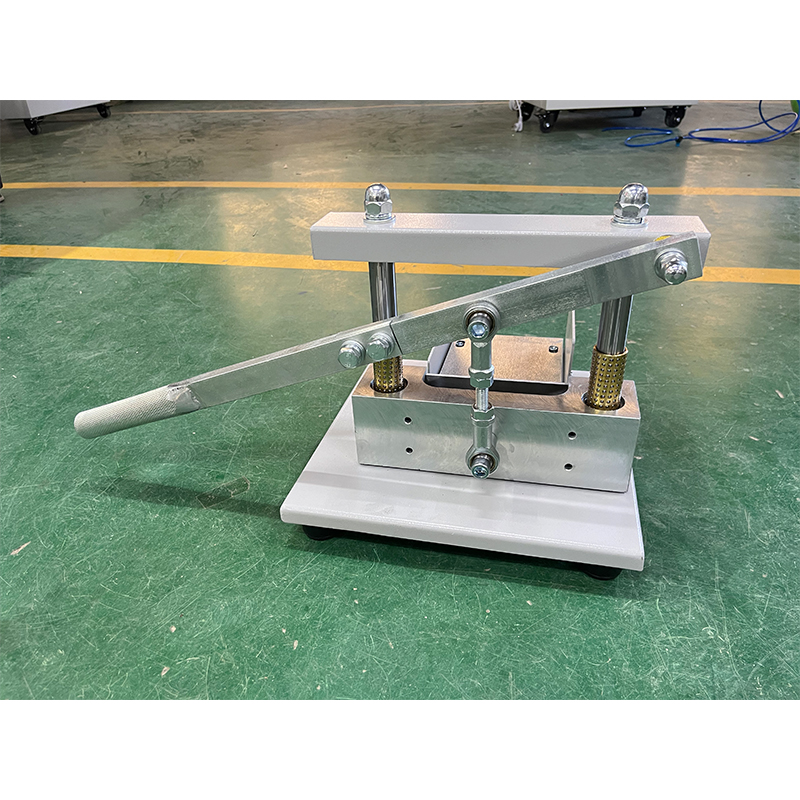

5. Mechanical Testing Equipment Mechanical properties such as tensile strength, flexibility, and abrasion resistance are critical for flexible cables. Equipment like tensile testers and dynamic fatigue testers evaluate these mechanical characteristics, providing insights into the cable's expected lifespan and performance under stress.

6. Electrical Performance Analyzers These analyzers measure various electrical properties such as capacitance, inductance, and resistance. They help in understanding how these properties influence the cable's performance in real-world applications. As electrical systems become more complex, the need for accurate electrical characterization has increased significantly in the Chinese market.

Advancements in Testing Technologies

The landscape of cable testing in China is rapidly evolving, with technological advancements leading the way. Digital and automated testing solutions have emerged, improving accuracy and efficiency. IoT-enabled testing equipment allows for remote monitoring and data collection, facilitating real-time analysis and decision-making. Additionally, software solutions that integrate with testing equipment help manage data more effectively, providing comprehensive insights into cable performance.

Conclusion

As China's industrial sector continues to thrive, the importance of robust flexible cables cannot be overstated. Testing equipment plays a vital role in ensuring these cables meet high standards of quality, safety, and performance. With advancements in technology, manufacturers and testing facilities in China are better equipped to tackle the challenges associated with flexible cables. By investing in state-of-the-art testing equipment, the industry can continue to elevate its standards, ultimately contributing to safer and more efficient electrical systems across various applications. The future of flexible cable testing in China looks promising, and as the market evolves, so too will the methodologies and technologies employed to ensure cable integrity and reliability.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy