China Insulation Resistance Testing Equipment for Reliable Electrical Safety Assessments

Understanding the Importance of Insulation Resistance Testing A Focus on China’s Testing Equipment

In the realm of electrical engineering, the significance of insulation resistance testing cannot be overstated. Insulation resistance testers are vital instruments used to assess the integrity of insulation in electrical components and systems. In China, where the manufacturing and usage of electrical equipment is vast and varied, the role of insulation resistance testing becomes even more paramount.

What is Insulation Resistance Testing?

Insulation resistance testing measures the resistance offered by insulation material to the flow of electric current. This value is crucial as it indicates how effectively an insulator can prevent current leakage. Over time, insulation can degrade due to chemical exposure, heat, moisture, or mechanical stress. Poor insulation can lead to equipment failure, short circuits, and potentially hazardous situations such as electrical fires. By using an insulation resistance tester, engineers and technicians can ensure that systems remain safe and compliant with safety standards.

The Importance of Insulation Resistance Testers

In China, where numerous industries rely on high-performance electrical systems, the maintenance of insulation integrity is critical. Insulation resistance testers come in various types, each designed for specific applications. For instance, there are handheld testers, bench-mounted models, and advanced multifunction units capable of performing several tests simultaneously.

The basic operating principle remains the same the tester applies a high voltage (usually between 250V and 5000V) to the insulation and measures the resistance in megaohms. A high resistance reading indicates good insulation, while low resistance suggests potential problems.

Why China Invests in Quality Testing Equipment

As one of the world’s largest manufacturers of electrical products, ensuring the quality and safety of these products is essential for China’s reputation in global markets. Insulation resistance testers play a critical role in quality assurance and compliance with international safety standards. Industries such as telecommunications, renewable energy, and manufacturing heavily invest in these testing devices to mitigate risks and enhance the reliability of their electrical systems.

The Chinese market has seen a considerable uptick in the demand for sophisticated insulation resistance testing equipment. Companies are not just looking for basic functionality but also for advanced features that include data logging, interfacing capabilities, and the ability to perform multiple tests. This trend is fueled by the rapid technological advancements and a growing emphasis on safety in the workplace.

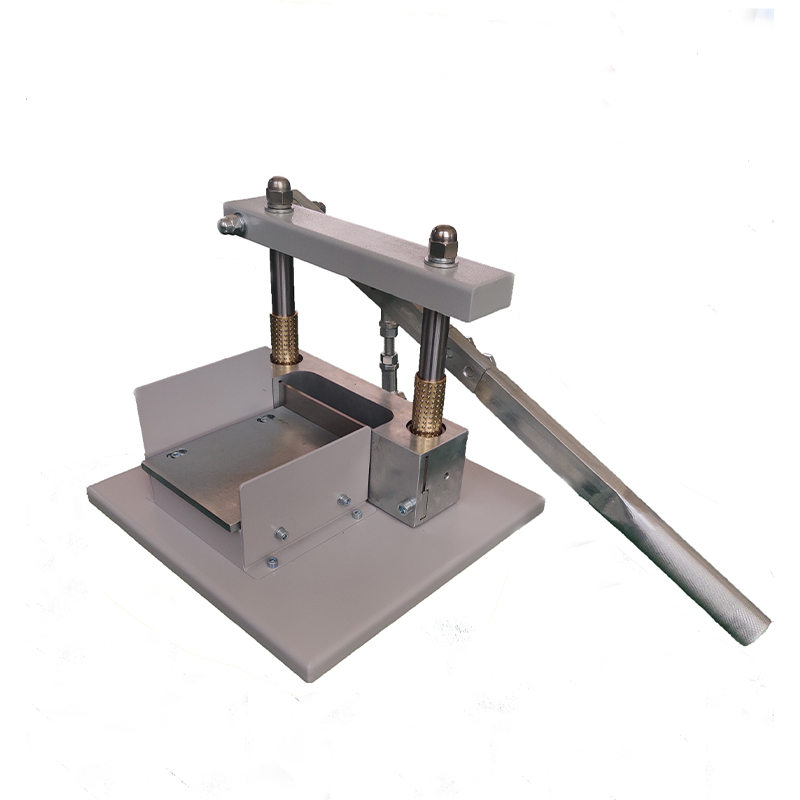

china insulation resistance tester

Types of Insulation Resistance Testers Available in China

The insulation resistance testing equipment market in China is diverse, catering to varying industry needs

. Some of the key types of testers available include1. Handheld Insulation Testers These portable devices are ideal for fieldwork, allowing technicians to conduct tests on-site effortlessly. They are particularly popular among electricians and maintenance personnel.

2. Multifunction Testing Devices These testers combine insulation resistance testing with other electrical measurements such as continuity, insulation voltage, and earth resistance. They offer comprehensive solutions for electrical inspections.

3. Automation-friendly Testers In the age of Industry 4.0, many manufacturers are looking for equipment that can integrate into automated systems. Some advanced testers now come with programmable features and can be linked to computer systems for real-time data analysis.

Conclusion The Future of Insulation Resistance Testing in China

As China continues to lead the world in technological innovation and manufacturing, the importance of insulation resistance testing will only grow. Advancements in testing equipment are making it easier and more efficient for companies to ensure the safety and reliability of their electrical products.

Moreover, with increased regulatory scrutiny on safety standards, industries will increasingly rely on high-quality insulation resistance testers. This reliance will boost investments in research and development, further improving the capabilities of insulation testing technologies.

In summary, insulation resistance testers are not just essential tools; they are critical to ensuring the safety and reliability of electrical systems in China. As industries evolve and adapt to new technologies, the importance of maintaining high insulation integrity through meticulous testing will remain a fundamental aspect of electrical engineering practices.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy