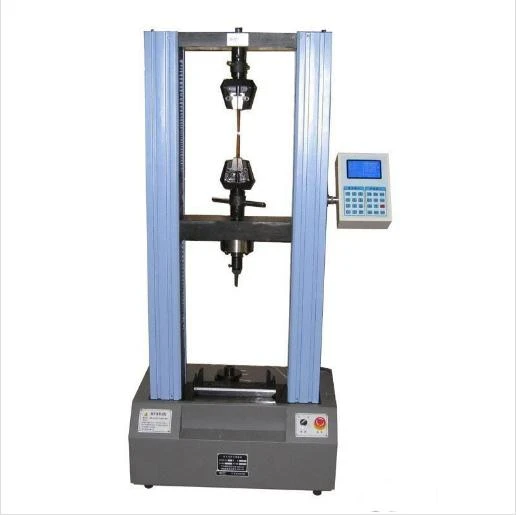

china tensile force tester

The Importance of Tensile Force Testing in China

Tensile force testing is a critical procedure used in various industries to determine the mechanical properties of materials. In China, where manufacturing and construction are vital sectors of the economy, the importance of tensile force testers cannot be overstated. These devices measure the force required to pull a material to the point of failure, providing essential data for quality control, product development, and research.

China stands as one of the world's largest manufacturing hubs, producing everything from textiles to heavy machinery. As such, the tension and durability of materials play a crucial role in ensuring that products can withstand the rigors of their intended use. Tensile force testing helps manufacturers ensure compliance with international standards, guaranteeing that products are reliable and safe for consumers.

The Importance of Tensile Force Testing in China

Manufacturers are increasingly adopting advanced tensile testing equipment, which integrates computer technology and automation to enhance testing accuracy and efficiency. Modern testers offer capabilities such as real-time data analysis, automatic data logging, and the ability to test multiple samples quickly. These advancements facilitate a more streamlined production process, reducing both time and costs while improving product quality.

china tensile force tester

Furthermore, tensile force testing is not limited to the production of new materials. It plays an essential role in evaluating the performance of existing products in the market. For instance, in the construction sector, tensile tests are crucial in assessing the integrity of steel reinforcements and other structural components. Any weaknesses in these materials could lead to catastrophic failures, making rigorous testing a non-negotiable aspect of construction design.

In addition to its application in manufacturing and construction, tensile testing has significant implications for product safety in consumer goods. For example, in the textile industry, tensile strength tests ensure that fabrics will not tear or break under stress. This guarantees consumer safety and enhances product durability and reliability. In an era where consumers are increasingly conscious of quality and performance, adherence to strict testing protocols can directly influence purchasing decisions and brand loyalty.

Moreover, the regulatory environment in China is evolving, necessitating more stringent quality controls. As the government emphasizes safety and quality standards, companies must comply with various regulations that often mandate regular tensile testing. This scenario creates a growing market for tensile testing services and equipment, opening up opportunities for businesses in equipment manufacturing, calibration, and servicing.

The future of tensile force testing in China looks promising, with increasing investments in research and development. As industries continue to innovate, the demand for advanced materials that offer superior performance is rising, driving the need for state-of-the-art testing methods. Integrating artificial intelligence and machine learning into testing processes may soon revolutionize how tensile properties are analyzed, leading to more precise predictions and tailored material solutions.

In conclusion, tensile force testing is an essential process in China’s manufacturing landscape, impacting a wide array of industries. As technological advancements continue to evolve, the importance of accurate and efficient tensile testing will only grow, ensuring that the quality and safety of products meet the highest standards. For manufacturers seeking to remain competitive and meet regulatory requirements, investing in dependable tensile force testing equipment is not just a choice but a necessity.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy