China Tensile Testing Equipment with Various Grip Options for Versatile Applications

Understanding Tensile Tester Grips in China A Comprehensive Overview

In the realm of material testing, the tensile tester is a crucial piece of equipment that measures the strength and ductility of materials. Its operation predominantly revolves around the use of grips, which secure the specimen during testing. In China, the market for tensile tester grips has been evolving rapidly, driven by advancements in technology and an increasing demand for testing services across various industries.

What are Tensile Tester Grips?

Tensile tester grips are specialized tools designed to hold test specimens in place while they are subjected to tensile forces. These grips ensure that the specimen does not slip or deform in a manner that could skew test results. The types of grips vary significantly based on the material being tested, the size of the specimens, and the specific testing standards involved. Common types include pneumatic grips, manual grips, and hydraulic grips, each designed for different applications and materials.

The Importance of Choosing the Right Grips

Selecting the appropriate grips for tensile testing is critical to obtaining accurate and reliable data. Improperly secured specimens can lead to premature failure, inaccurate measurements, and compromised test integrity. For instance, if the grips are too loose, the specimen may slip, resulting in a lower measured tensile strength. Conversely, if the grips are too tight, they could cause stress concentrations in the specimen, leading to erroneous results.

In China, manufacturers of tensile tester grips are increasingly recognizing the need for custom solutions tailored to specific materials and testing conditions. This bespoke approach allows for improved test accuracy and repeatability, essential factors for industries such as aerospace, automotive, and construction.

Technological Advancements and Innovations

The Chinese market for tensile tester grips is witnessing significant technological advancements. Innovations such as advanced materials for grips, automated grip systems, and smart grips equipped with sensors for real-time data collection are becoming commonplace. These advancements not only enhance the performance of tensile testers but also streamline the testing process, making it more efficient.

china tensile tester grips

For instance, smart grips can provide instant feedback regarding the state of the specimen during testing. This information can be invaluable for quality control and material research, allowing engineers to make informed decisions based on real-time data.

The Regulatory Landscape

The manufacturing and use of tensile tester grips in China are subject to various international and national testing standards, including ISO, ASTM, and GB standards. Compliance with these regulations is crucial for manufacturers and users of tensile testers, ensuring that the grips not only perform as intended but also meet safety and quality benchmarks.

In recent years, there has been an increasing emphasis on quality assurance and quality control processes in Chinese manufacturing. Companies are adopting international best practices to ensure that their products align with global standards. This shift has led to improved trust in Chinese products, particularly in the machinery and testing equipment sectors.

Market Trends and Future Outlook

The market for tensile tester grips in China is expected to continue growing, fueled by the country's expanding manufacturing sector and rising demand for quality assurance in various industries. Additionally, as Chinese manufacturers aim to compete globally, there will be a greater push towards innovation and development of high-quality testing equipment.

The integration of automation and artificial intelligence into material testing processes, including the development of more sophisticated grips, will likely shape the future of tensile testing in China. As companies invest in research and development, we can expect to see a wave of new products that enhance testing accuracy and efficiency.

Conclusion

In conclusion, tensile tester grips are an essential component of tensile testing, playing a vital role in ensuring accurate and reliable test results. In China, the market for these grips is evolving rapidly, influenced by technological advancements and stringent regulatory standards. As industries continue to prioritize quality and performance, the development and refinement of tensile tester grips will remain a focal point for manufacturers and researchers alike. Embracing innovation in this area will undoubtedly lead to better, more reliable material testing outcomes in the future.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

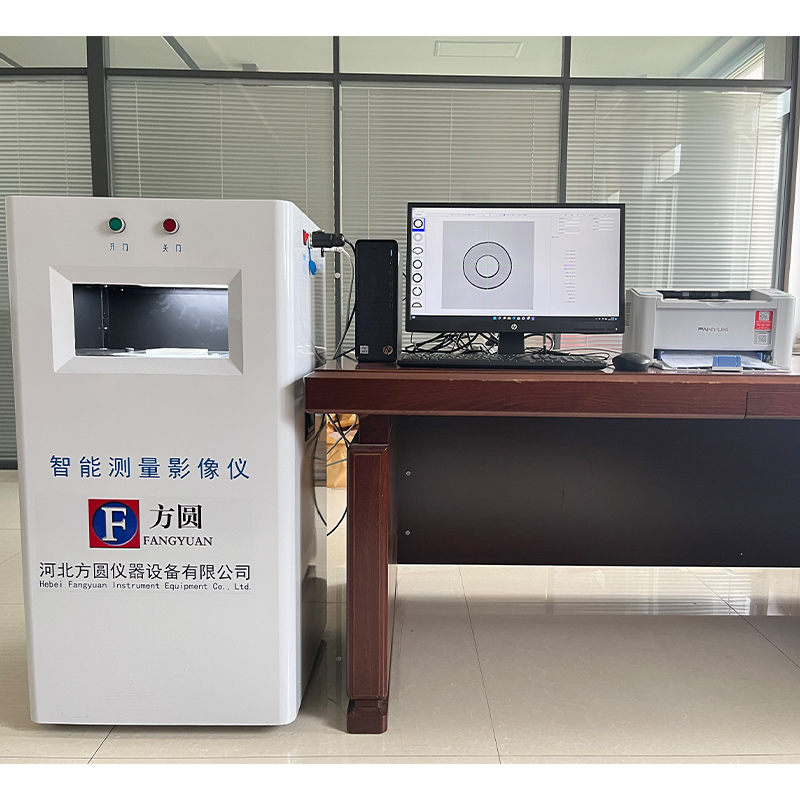

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy