China Vertical Profile Measurement Projector for Precision Inspection and Analysis

China's Vertical Profile Projector Revolutionizing Precision Measurement in Manufacturing

In the realm of precision measurement, the vertical profile projector stands out as an indispensable tool, especially within the manufacturing sector. As industries continue to evolve, particularly in countries like China, the demand for high-precision measurement instruments has surged. The China Vertical Profile Projector, a sophisticated optical measuring device, plays a crucial role in ensuring that components meet the stringent tolerances required for modern engineering and manufacturing.

The vertical profile projector operates on the principle of projecting magnified images of parts or components onto a screen, where operators can analyze the shapes and dimensions with high accuracy. This projector utilizes various light sources along with optical lenses to cast a shadow of the object onto a flat surface, allowing operators to measure complex geometries that would otherwise be challenging to assess via traditional measuring instruments. The innovation of integrating digital measuring systems into these projectors has further enhanced their functionality, providing real-time data and improving measurement efficiency.

China's Vertical Profile Projector Revolutionizing Precision Measurement in Manufacturing

One of the key advantages of using the vertical profile projector is its versatility. It can be applied to a wide range of materials, from metals to plastics, accommodating numerous profiles and geometries. This adaptability makes it a preferred choice in quality assurance laboratories and production floors alike. Moreover, the ease of operation ensures that even personnel with limited training can effectively utilize the machine to obtain precise measurements, thus streamlining the manufacturing process.

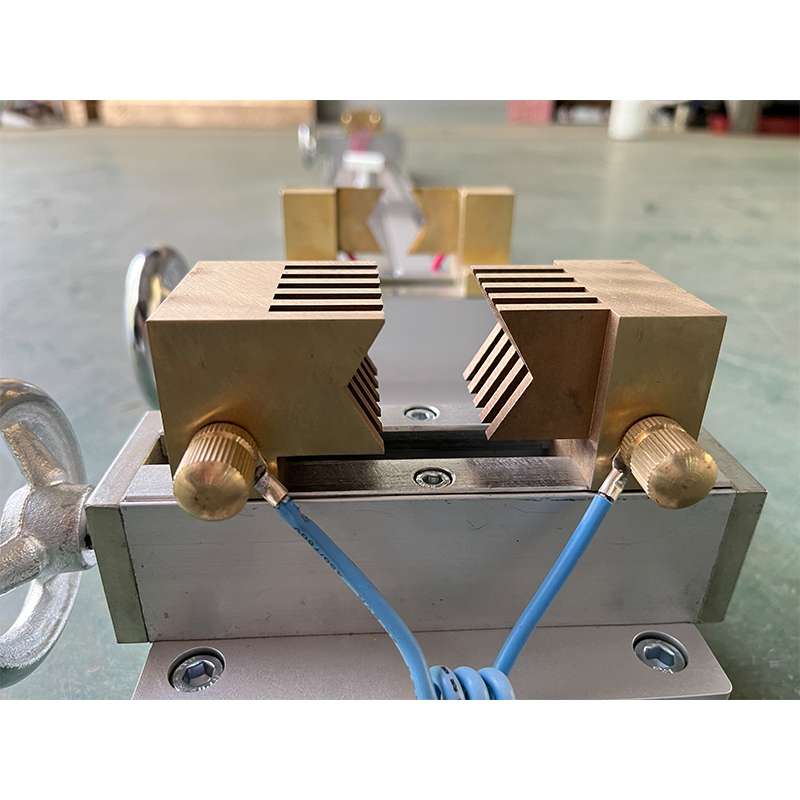

china vertical profile projector

In China, several leading manufacturers have adopted the vertical profile projector not just for measurement, but also as a diagnostic tool during the product development phase. Designers and engineers can utilize the device to prototype and evaluate their designs, identifying potential flaws before full-scale production. This proactive approach to design and quality control can significantly reduce costs related to rectifying defects in later production stages.

Furthermore, the integration of advanced features such as computer numerical control (CNC) technology and software analytics into modern vertical profile projectors has transformed their operational capabilities. The use of CNC allows for automated precision measurements, drastically increasing throughput while reducing human error. Software analytics can process the data collected, providing insights into manufacturing trends and aiding in predictive maintenance, thus ensuring the longevity and reliability of both the machinery and the products being created.

As China's manufacturing landscape continues to modernize and automate, investments in vertical profile projectors are anticipated to rise. With the increasing competition in global markets, Chinese manufacturers are prioritizing methods that bolster efficiency and precision. The growing emphasis on high-quality production is leading to the widespread adoption of advanced measurement technologies and the vertical profile projector is undoubtedly at the forefront of this transition.

In conclusion, the China Vertical Profile Projector represents a significant advancement in precision measurement technology within the manufacturing sector. Its ability to provide accurate, reliable measurements of intricate components plays a vital role in maintaining the integrity of engineering standards and enhancing overall production quality. As the industry evolves, embracing the latest technologies will be paramount for manufacturers aiming to sustain competitive advantage and achieve excellence in production. The vertical profile projector not only exemplifies this trend but also heralds a new era of precision and efficiency in manufacturing practices across China and beyond.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy