China Wire Bending Testing Equipment for Quality and Durability Assessment

Understanding the China Wire Bending Test Machine An Essential Tool for Quality Assurance in Manufacturing

The wire bending test machine, particularly those manufactured in China, plays a critical role in the quality assurance processes of numerous industries. As the demand for high-quality wire products surges across various sectors, including automotive, aerospace, and electronics, the need for reliable testing equipment has never been more pronounced. This article delves into the significance of wire bending test machines, their operational mechanisms, and the advantages they offer manufacturers.

The Importance of Wire Bending Tests

Wire bending tests are essential for assessing the mechanical properties and durability of wire materials. These tests help determine how well a wire can withstand stress, fatigue, and deformation when subjected to bending forces. By simulating real-world conditions, manufacturers can identify potential weaknesses in their wire products, leading to improvements in design and material selection.

For instance, in the automotive industry, wires are often used in critical applications such as ignition systems, sensors, and electrical harnesses. Any failure in these components can lead to significant safety hazards and costly recalls. Thus, rigorous testing using wire bending machines becomes crucial for ensuring product reliability and compliance with industry standards.

Features of China Wire Bending Test Machines

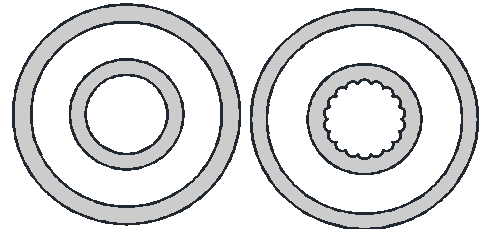

China wire bending test machines are designed with advanced technology that enables precise bending tests on various wire types. These machines typically feature a robust frame, high-precision measuring instruments, and user-friendly interfaces. Key features often include

1. Versatile Bending Capabilities Many machines can perform a range of bending angles and cycles, allowing manufacturers to test different wire configurations. This versatility ensures that manufacturers can test their materials under numerous conditions.

2. Automated Testing Processes Modern machines often come equipped with automation features that allow for consistent and repeatable testing processes. This automation reduces human error, increases throughput, and ensures that test results are reliable.

3. Data Collection and Analysis Most wire bending test machines are equipped with software that allows for real-time data collection. Manufacturers can analyze the resistance of wire to bending, fatigue life, and other critical parameters. This data is invaluable for making informed decisions about material properties and design improvements.

china wire bending test machine

4. Durability and Reliability Given the towering scale of industries in China, the machines are built to withstand rigorous testing conditions and long operational hours without compromising accuracy.

Benefits of Using Wire Bending Test Machines

Utilizing wire bending test machines offers substantial benefits for manufacturers

- Quality Control By implementing bending tests, manufacturers can uphold stringent quality control standards. Identifying weak points in wire materials before they are used in production helps mitigate risks associated with product failures.

- Cost Efficiency Investing in a wire bending test machine can lead to long-term cost savings. By preemptively identifying flawed materials or designs, manufacturers can avoid costly rework and warranty claims.

- Regulatory Compliance Many industries are governed by strict regulatory frameworks. Using wire bending test machines ensures that products meet safety and performance standards, thus enhancing the reputation of a brand.

- Innovation Facilitation With detailed data from bending tests, engineers can experiment with new wire designs and materials, fostering innovation. Continuous improvement strategies are supported by the insights gleaned from testing.

Conclusion

As industries continue to evolve, the importance of rigorous testing practices becomes increasingly clear. The China wire bending test machine stands out as an indispensable tool for manufacturers aiming to enhance quality, efficiency, and safety in their products. By adopting this advanced testing technology, companies can stay ahead of the curve, minimizing risks while promoting a culture of excellence in manufacturing. With the right equipment, businesses are better equipped to meet the demands of a competitive market, ensuring they deliver superior products that meet or exceed customer expectations. In this context, investing in a wire bending test machine is not just a technical enhancement; it is a strategic decision that pays dividends in the long run.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy