china wire bending test machine

Understanding the China Wire Bending Test Machine A Comprehensive Overview

In the realm of materials testing, the wire bending test machine is a pivotal device extensively utilized across various industries, especially in the fields of manufacturing and construction. China, as a leading player in manufacturing machinery, has developed robust and advanced wire bending test machines, designed to assess the durability and resilience of wire materials under bending conditions. This article will delve into the significance of these machines, their functionalities, and their applications across different sectors.

What is a Wire Bending Test Machine?

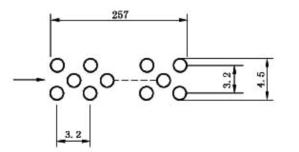

A wire bending test machine is specifically designed to evaluate the mechanical properties of wire materials by simulating the bending forces that the wires would encounter in real-world applications. This test is crucial for determining the wire's ability to withstand mechanical stress without failing or deforming. The machine applies a controlled force to bend the wire at specified angles, measuring the wire's elasticity, strength, and overall bendability.

Importance of Wire Bending Tests

Wire bending tests play a significant role in quality control and assurance in manufacturing processes. By testing wire materials, manufacturers can identify potential weaknesses, ensuring that they meet industry standards and regulations. The results from these tests help engineers and designers make informed decisions regarding material selection and product design. Furthermore, these tests are essential for products that require precise bending capabilities, such as springs, hooks, and various other components used in automotive, aerospace, and construction industries.

Key Features of China’s Wire Bending Test Machines

China's wire bending test machines are equipped with several advanced features that enhance their performance and reliability

1. Precision Control Systems Modern machines utilize computer-controlled systems that allow for precise adjustments to the bending angles and forces applied to the wire. This feature ensures that tests can be replicated accurately, leading to reliable results.

2. Data Acquisition Systems Many machines come with integrated data logging capabilities, enabling users to collect and analyze test data efficiently. This feature is essential for maintaining records and compliance with industry standards.

china wire bending test machine

3. Versatile Testing Configurations Chinese manufacturers offer machines that can perform a range of bending tests, including 180-degree bends, cyclic bending, and even torsion tests. This versatility caters to different materials and specific testing requirements.

4. User-Friendly Interfaces With the advancement of technology, many wire bending test machines now provide intuitive interfaces that simplify operation for users of varying expertise. This ease of use promotes efficiency and accuracy in testing procedures.

5. Robust Build Quality Machines designed in China are often built to withstand rigorous testing environments, ensuring long-term durability and reliability. They are constructed from high-quality materials to resist wear and tear over time.

Applications Across Industries

The applications of wire bending test machines are extensive and span across several sectors

- Automotive Industry In automotive manufacturing, wire products such as springs, cables, and connectors are regularly subjected to bending tests to ensure their durability under stress. - Aerospace Aerospace components demand the highest levels of safety and reliability, making rigorous testing of wire materials critical in this sector.

- Construction In construction, wires and reinforcement bars undergo bending tests to assess their strength and flexibility, ensuring that structures can withstand environmental and structural stresses.

- Electronics Wire bending tests are important in the electronics industry, where wires must maintain integrity during assembly and use.

Conclusion

In conclusion, wire bending test machines developed in China play an invaluable role in testing and validating the performance of wire materials across various industries. Their advanced features and user-friendly designs enhance the testing process, promoting higher standards of quality and safety in manufacturing. As industries continue to evolve, the significance of reliable testing methodologies, such as those provided by wire bending test machines, will only grow, reinforcing the importance of this essential equipment in our increasingly engineered world.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy