clamps for tensile testers factories

Exploring Clamps for Tensile Testers A Vital Component in Material Testing

In the realm of materials testing, precision and reliability are paramount. Among the essential components that contribute to the accuracy of tensile tests are clamps. These seemingly simple devices play a crucial role in holding and securing specimens during testing processes, ensuring that results are both valid and reproducible. In this article, we will explore the importance of clamps for tensile testers, their types, and the manufacturing processes involved in creating these indispensable tools.

The Importance of Clamps in Tensile Testing

Tensile testing measures the mechanical properties of materials, providing insights into various characteristics such as strength, ductility, and elasticity. During this process, a sample material is subjected to a controlled pulling force until it fractures. Clamps are critical in this scenario as they anchor the specimen tightly to prevent slippage, which could lead to inaccurate readings and potentially disastrous consequences in the case of safety-critical applications.

The requirement for clamps is particularly pronounced because different materials exhibit various behaviors under tensile stress. For instance, metals might require robust clamps due to their strength, while softer materials like plastics may need gentler clamps to avoid damage. Thus, the design and manufacturing of these clamps are tailored to meet the varied needs of diverse materials.

Types of Clamps for Tensile Testers

Clamps can be categorized into several types based on their design and application

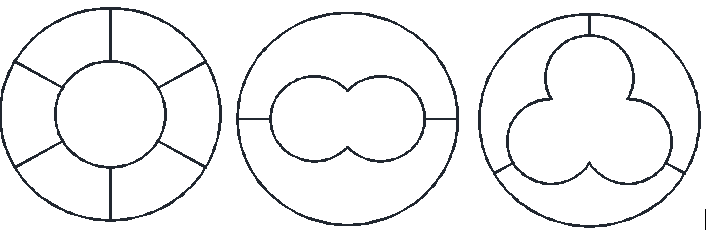

1. Mechanical Clamps These are among the most common types used in tensile testing. They function by utilizing a lever mechanism to tightly grip the material. Mechanical clamps are often favored for their simplicity and effectiveness, providing a reliable hold on a broad range of materials.

2. Wedge Clamps Known for their superior grip, wedge clamps employ a wedge mechanism that expands when force is applied, thus securing the specimen firmly in place. They are particularly useful for testing brittle materials, as they minimize the risk of introducing stress concentrations that could lead to premature failure.

clamps for tensile testers factories

3. Hydraulic Clamps These clamps utilize hydraulic pressure to provide a strong grip on the specimen. They are ideal for testing high-strength materials or those that require significant force to be applied without slippage. The ability to adjust the grip force precisely enhances the versatility and accuracy of testing.

4. Pneumatic Clamps Leveraging air pressure, pneumatic clamps are known for their quick actuation and ease of use. They are often used in automated testing environments where speed is essential, offering reliable performance without manual intervention.

5. Custom Clamps For specialized testing applications, manufacturers often design custom clamps tailored to specific materials or testing requirements. These clamps can be engineered to handle unique shapes, sizes, or loading conditions, ensuring that the testing process remains efficient and accurate.

Manufacturing Clamps for Tensile Testers

The manufacturing of clamps involves several critical steps to ensure they meet the rigorous demands of tensile testing. It begins with the selection of high-quality materials, typically metals such as aluminum or steel, which exhibit strength and durability. The manufacturing process often includes CNC machining, which allows for precise shaping and dimensioning of the clamps.

Post-manufacturing, clamps often undergo various finishing processes, such as anodizing or powder coating, to enhance corrosion resistance and durability. Additionally, quality control tests are conducted to verify the effective gripping capabilities of the clamps and to check for any defects that could compromise testing performance.

Conclusion

Clamps for tensile testers are an essential element in the field of materials testing. Their roles are pivotal in ensuring accurate and reliable results, which are crucial for industries that rely on the integrity of materials. With various types available to cater to different testing needs, and a stringent manufacturing process to ensure quality, these clamps represent the intersection of engineering precision and material science. As technology advances, we can expect to see continued innovation in the design and functionality of these devices, further enhancing the reliability of tensile testing across various applications.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy