clamps for tensile testers suppliers

Understanding Clamps for Tensile Testers A Guide for Suppliers

When it comes to material testing, especially tension or tensile testing, the importance of high-quality clamps cannot be overstated. Tensile testers are vital in determining the mechanical properties of materials, including their strength, ductility, and elasticity. In this context, clamps play a crucial role, as they securely hold the test specimens in place while sufficient force is applied. This article explores the different types of clamps used in tensile testing, their features, and considerations for suppliers in this niche market.

Importance of Clamps in Tensile Testing

Clamps are essential components of any tensile testing machine. They are responsible for gripping the test specimen without causing damage, ensuring accurate and reliable test results. A poorly designed or improperly functioning clamp can lead to slippage or uneven stress distribution, rendering the test invalid. Thus, suppliers must pay close attention to the types of clamps they offer and their suitability for various materials and testing scenarios.

Types of Clamps

1. Mechanical Clamps These clamps operate via a mechanical locking mechanism that provides a strong grip on the specimen. Mechanical clamps are often adjustable, allowing them to accommodate different specimen dimensions. They are favored for their simplicity and reliability in various testing conditions.

2. Hydraulic Clamps For heavy-duty applications or larger specimens, hydraulic clamps are preferred due to their ability to exert greater force without manual effort. These clamps provide uniform pressure across the specimen, reducing the likelihood of damage during testing. Suppliers need to ensure that these clamps are compatible with the hydraulic systems of respective tensile testers.

3. Pneumatic Clamps Similar to hydraulic clamps, pneumatic clamps use air pressure to secure the specimen. They are appreciated for their speed and efficiency, particularly in high-throughput testing environments. Suppliers must ensure that pneumatic clamps are designed for quick release and reloading, enhancing overall testing efficiency.

4. Specialty Clamps Certain applications may require custom or specialized clamps designed for specific materials or testing requirements. For instance, clamps for soft materials might have rubber padding to prevent slippage, while those designed for brittle materials may have reinforced edges to minimize breakage. Suppliers need to cater to diverse industry needs by offering customized solutions.

Factors to Consider When Choosing Clamps

clamps for tensile testers suppliers

When selecting clamps for tensile testers, several critical factors should be taken into account

- Material Compatibility Different materials respond uniquely under tensile stress. Clamps must be made from materials that can withstand the same environmental conditions as the specimens being tested.

- Clamping Force Understanding the specifications of the tensile tester is critical. Suppliers should provide clamps that can generate adequate clamping force to securely hold the specimen without risking damage.

- Ease of Use A clamp's design should prioritize user-friendliness. Operators should be able to load and unload specimens quickly, which is vital in high-demand testing facilities.

- Durability and Maintenance The lifespan and maintenance requirements of clamps will impact overall operational costs. Suppliers must offer high-quality materials that endure repeated use with minimal wear.

- Cost Considerations While quality is paramount, suppliers also need to consider cost-effectiveness. Offering a range of clamps for different budget levels can make their products more accessible to a wider audience.

Conclusion

Clamps are an integral component of tensile testing equipment, significantly influencing the accuracy and reliability of test results. For suppliers, understanding the various types of clamps, their applications, and the factors influencing their effectiveness can make a tremendous impact on customer satisfaction and long-term success in the industry. By focusing on quality, compatibility, usability, and customer needs, suppliers can provide robust solutions that enhance the performance of tensile testers and support the rigorous demands of material testing.

With the continuous advancement of testing technology, staying updated on the latest designs and functionalities of clamps will enable suppliers to maintain their competitive edge in this specialized market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

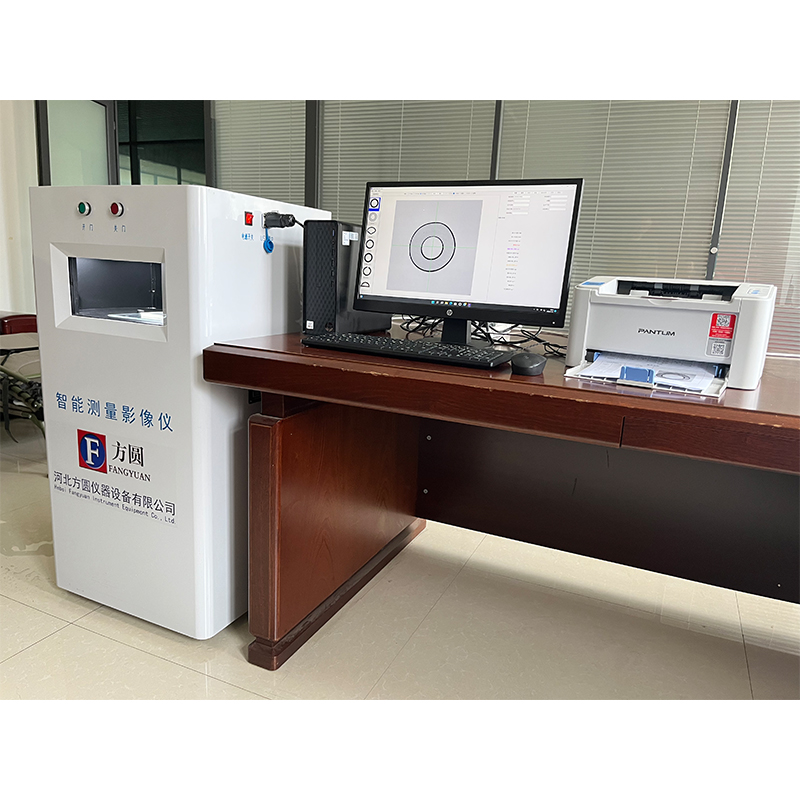

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy