Coaxial Cable Cutter Manufacturing Facilities and Production Insights

The Importance of Coaxial Cable Slicers in Manufacturing

Coaxial cables are an essential component in various communication systems, connecting devices efficiently while maintaining signal integrity. The production of these cables necessitates precise manufacturing processes, one of which is the slicing or cutting of the cable to desired lengths. This is where coaxial cable slicer factories come into play, providing the necessary technology and machinery to ensure high-quality production.

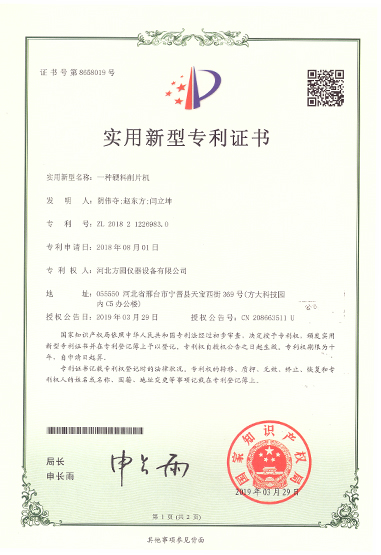

Coaxial cable slicers are specialized machines designed to cut coaxial cables with precision. The design of these slicers incorporates advanced technology to ensure uniformity and accuracy, minimizing waste and enhancing production efficiency. Factories that manufacture these slice tools focus on engineering solutions that cater to different cable sizes and specifications, ensuring versatility in their applications.

The process of slicing coaxial cables is critical because any inconsistencies during this step can lead to signal loss or degradation. Factories utilize sophisticated techniques such as oscillating blades or laser cutting technology to create clean cuts without damaging the cable's internal structure. This ensures that both the inner conductor and the insulating layers remain intact, preserving the cable's functionality.

coaxial cable slicer factories

In addition to precision, coaxial cable slicer factories emphasize safety and ease of use. Modern slicers are designed with user-friendly interfaces and built-in safety features to protect workers during operation. This focus on safety is paramount, as handling machinery involves inherent risks. Factories often invest in training programs for their employees to promote operational safety and efficiency.

The demand for coaxial cables continues to rise with advancements in telecommunications and data transmission technologies. Consequently, the role of coaxial cable slicer factories is becoming increasingly important. These manufacturing facilities not only supply the tools required for cable production but also innovate to adapt to evolving industry standards. By implementing automated cutting solutions, they can meet larger production demands while maintaining high-quality outputs.

Moreover, ecological concerns are leading these factories to seek more sustainable practices. By optimizing their cutting processes and reducing material waste, coaxial cable slicer manufacturers are contributing to a greener production outlook. This commitment to sustainability is becoming a significant selling point, appealing to environmentally conscious consumers and businesses alike.

In conclusion, coaxial cable slicer factories play a crucial role in the manufacturing and telecommunications sectors. Their focus on precision, safety, and sustainable practices ensures the continuous supply of high-quality coaxial cables essential for today’s technology-driven world. As the industry evolves, these factories will undoubtedly remain at the forefront of innovation, shaping the future of cable production.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy