coaxial cable slicer factory

The Coaxial Cable Slicer Factory Innovating Cable Solutions

In today’s fast-paced technological landscape, coaxial cables play a critical role in a myriad of applications ranging from television broadcasts to internet connectivity. As the demand for high-quality coaxial cables continues to rise, so does the need for efficient manufacturing tools, such as coaxial cable slicers. A coaxial cable slicer factory specializes in producing advanced slicing equipment that streamlines the process of cutting coaxial cables with precision and speed.

The Anatomy of a Coaxial Cable Slicer

A coaxial cable consists of a central conductor, an insulating layer, a metallic shield, and an outer sheath. Due to its construction, slicing coaxial cables requires specialized tools to ensure clean cuts that do not damage any components. A coaxial cable slicer is designed to take into account the unique structure of these cables. It typically features adjustable blade systems that allow for varying diameters of cables, ensuring consistency and accuracy in every cut.

The factory environment is equipped with sophisticated machinery and technology that facilitate the production of these slicers. High-precision cutting tools, laser alignment systems, and automated assembly lines are just a few examples of the innovations that contribute to high-quality output. The integration of CNC (Computer Numerical Control) technology means that manufacturers can ensure each slicer is built to exact specifications, which is crucial for meeting industrial standards.

Quality Control in Coaxial Cable Slicer Manufacturing

Quality control is paramount in any manufacturing process, especially in the production of equipment used for precision tasks. Coaxial cable slicer factories implement rigorous testing protocols to ensure that each slicer meets the demanding standards of performance required by professionals in the field. During the manufacturing process, every component is meticulously inspected for defects, and the final product undergoes comprehensive testing to guarantee durability and cutting precision.

Moreover, manufacturers often adhere to international quality management standards, such as ISO certification, which assures customers that the products meet specified requirements and are consistently embraced for quality and safety. This commitment to excellence helps build trust with clients who depend on these tools for their operations.

coaxial cable slicer factory

Customization and Versatility

One of the key advantages of a coaxial cable slicer factory is the ability to offer customization options. Different industries may have unique requirements regarding cable dimensions or cutting techniques, and manufacturers can work closely with clients to create tailor-made solutions. Whether it’s a handheld slicer for small business use or a high-capacity machine for industrial applications, the flexibility to accommodate various needs is a significant asset.

Furthermore, some factories also produce slicers that integrate additional functionalities, such as stripping or crimping, which can enhance the efficiency of cable assembly processes. This versatility positions coaxial cable slicers as essential tools for a wide range of users, from hobbyists to large-scale telecommunications companies.

The Future of Cable Slicing Technology

As we move further into the digital age, the landscape of telecommunications continues to evolve. The coaxial cable slicer factory is positioned at the forefront of this transformation, innovating to meet the challenges of modern technology. With the rise of fiber optics and newer communication technologies, there is an increasing trend towards hybrid solutions that incorporate both coaxial and fiber cables.

This evolution indicates that manufacturers must remain agile, investing in research and development to stay ahead of industry trends. The future may see the emergence of smart slicers equipped with sensors and connectivity options, allowing for data tracking and enhanced user interfaces. By embracing innovation, coaxial cable slicer factories can ensure they remain vital contributors to the telecommunications supply chain.

Conclusion

The coaxial cable slicer factory is an indispensable part of the telecommunications ecosystem, providing essential tools that facilitate the seamless production and maintenance of coaxial cables. With stringent quality control measures, customizable solutions, and a commitment to innovation, these factories not only enhance operational efficiencies for their clients but also play a vital role in the advancement of communication technologies worldwide. As they continue to adapt to changing market demands, the future looks promising for manufacturers and users alike.

-

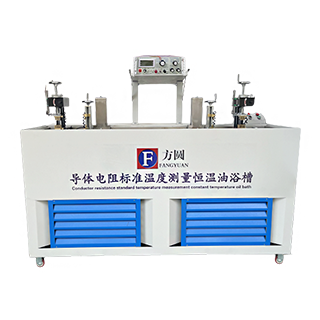

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy