computer control electronic tensile tester manufacturer

The Rise of Computer-Controlled Electronic Tensile Tester Manufacturers

In today's industrial landscape, the demand for precision and efficiency is at an all-time high. This necessitates the use of advanced testing equipment, particularly in the fields of materials science, manufacturing, and quality control. Among the most critical tools for evaluating material properties is the computer-controlled electronic tensile tester. This sophisticated equipment allows manufacturers to conduct tensile strength tests with remarkable accuracy and consistency, which is essential for ensuring product reliability.

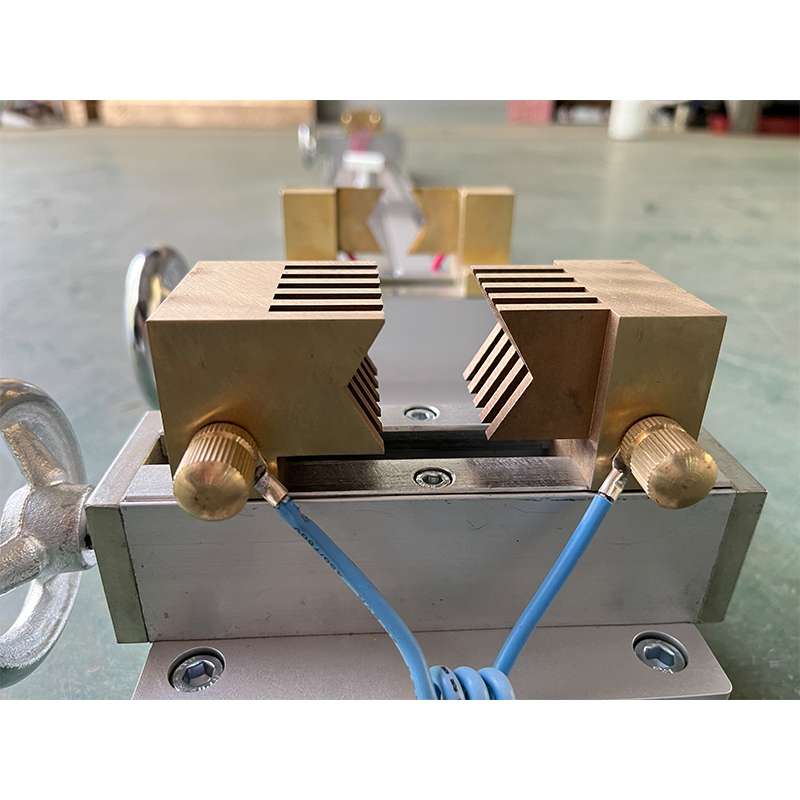

Computer-controlled electronic tensile testers are designed to assess the strength, elasticity, and ductility of materials by applying a controlled tensile force until the material fractures. By integrating computer technology with tensile testing, manufacturers can achieve a level of precision that is unimaginable with traditional mechanical testers. These modern devices utilize various sensors and data acquisition systems, enabling them to record and analyze real-time data during testing. This capability not only enhances the accuracy of results but also streamlines the testing process.

The rise of computer-controlled electronic tensile tester manufacturers can be attributed to several factors. First and foremost is the increasing emphasis on quality control within industries such as construction, automotive, aerospace, and textiles. As these sectors strive for excellence, they require testing solutions that meet stringent industry standards. Computer-controlled testers are capable of performing complex tests and providing detailed reports that comply with international testing standards.

computer control electronic tensile tester manufacturer

Additionally, advancements in technology have made these systems more accessible and user-friendly. Manufacturers now offer a variety of models tailored to meet the specific needs of different industries. From entry-level testers suitable for educational institutions to high-capacity machines designed for heavy-duty industrial applications, there is a solution for every requirement. This versatility is a significant advantage, allowing companies to choose a system that aligns with their operational demands and budget constraints.

Furthermore, the development of software solutions that accompany these testers adds to their appeal. Software platforms provide sophisticated data analysis functionalities, enabling users to interpret results effectively and derive meaningful insights. This makes it possible for manufacturers to implement data-driven decision-making processes, leading to continual improvement in product quality and performance.

In conclusion, the emergence of computer-controlled electronic tensile tester manufacturers reflects the industry's need for precise, reliable, and efficient testing equipment. As industries continue to evolve and innovate, the role of these testers will only grow in importance. By investing in advanced testing solutions, manufacturers can ensure that they remain competitive in a challenging market, ultimately driving progress in material science and engineering. The future of tensile testing is undoubtedly intertwined with the advancements in computer technology, leading to an exciting era of possibilities for quality assessment and improvement.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy