computer control universal tensile testing machine company

Advancements in Computer-Controlled Universal Tensile Testing Machines

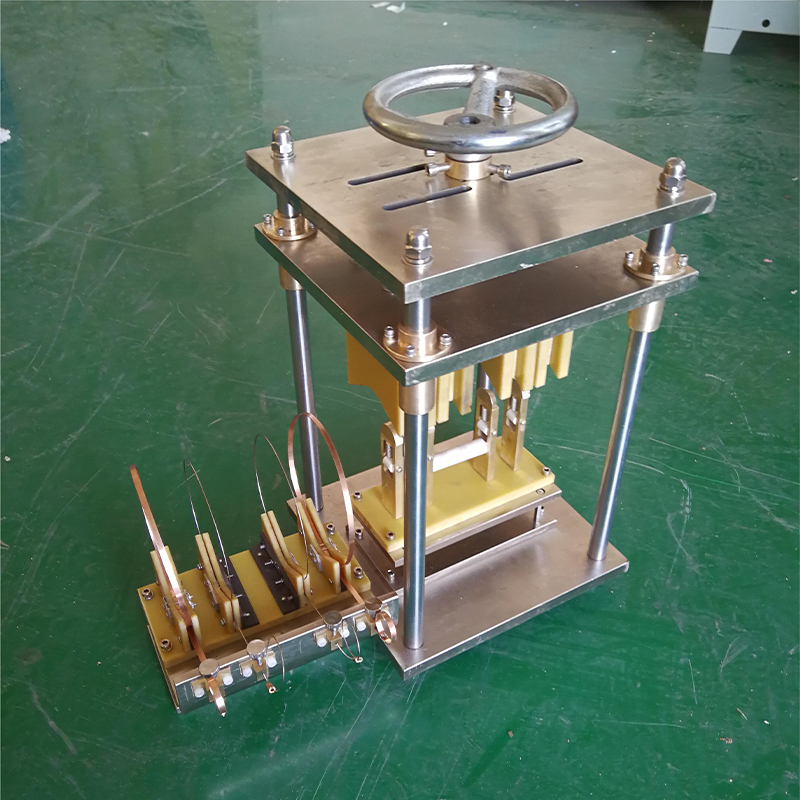

In the realm of material testing, the importance of precision and reliability cannot be overstated. Computer-controlled universal tensile testing machines have emerged as indispensable tools in laboratories and industrial settings, providing robust solutions for evaluating the mechanical properties of various materials, including metals, polymers, and composites.

A universal tensile testing machine is designed to apply forces to a material specimen until it fails, thereby determining key parameters such as tensile strength, yield strength, elongation, and modulus of elasticity

. The integration of computer control in these machines has significantly enhanced their capabilities, ensuring higher accuracy and repeatability in tests.One of the pivotal advantages of computer-controlled tensile testing machines is their ability to automate the testing process. Operators can input specific test parameters and protocols directly into the software interface. This automation not only saves time but also minimizes human error, allowing for more consistent results across multiple tests. The machines are equipped with advanced data acquisition systems that provide real-time monitoring and recording of test data, facilitating comprehensive analysis and reporting.

computer control universal tensile testing machine company

Moreover, modern tensile testing machines come with sophisticated software that supports various testing standards, such as ASTM, ISO, and EN. This adaptability is crucial for industries that must comply with stringent regulatory requirements. The software often includes features for graphical representation of test results, enabling engineers and material scientists to visualize stress-strain curves and other critical data.

The versatility of computer-controlled universal tensile testing machines also extends to their application in research and development. In the quest for innovative materials, researchers can quickly assess the mechanical properties of new composites or alloys, thereby accelerating the development process. This is particularly vital in industries such as aerospace, automotive, and construction, where the performance of materials is paramount.

In summary, the development of computer-controlled universal tensile testing machines marks a significant leap forward in material testing technology. Their automation capabilities, compliance with international testing standards, and extensive application in R&D make them essential tools in today’s advanced manufacturing landscape. As industries continue to evolve, these testing machines will play a critical role in ensuring the safety, reliability, and performance of materials used in various applications. The future of material testing is indeed bright with these innovative solutions at the forefront.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy