Automated Electronic Tensile Test System for Enhanced Material Strength Analysis

The Role of Computer-Controlled Electronic Tensile Testers in Material Testing

The significance of tensile testing in material science cannot be overstated. As materials are subjected to various stresses in real-world applications, understanding their properties under tension is crucial for ensuring safety and performance. Among the modern tools utilized for this purpose, computer-controlled electronic tensile testers stand out for their precision, versatility, and user-friendly interfaces.

A computer-controlled electronic tensile tester is a device designed to assess the mechanical properties of materials by applying a controlled tensile force until the material fails. These testers can evaluate various materials, including metals, plastics, and composites, making them indispensable in industries such as aerospace, automotive, construction, and manufacturing.

One of the primary advantages of computer-controlled tensile testers is their ability to deliver precise measurements of tensile strength, elongation, yield strength, and modulus of elasticity. This level of accuracy is achieved through advanced sensors and software algorithms that monitor the applied force and the corresponding elongation of the specimen in real-time. The data collected during these tests can be analyzed to produce stress-strain curves, which are critical for understanding a material's behavior under load.

The automation provided by computer control also enhances the reliability of the testing process. Manual testing can introduce human error, leading to inconsistent results. In contrast, computer-controlled testers follow standardized protocols, ensuring that each test is performed under identical conditions. This consistency is particularly vital for quality assurance in manufacturing environments where material properties must meet specific regulations or standards.

computer control electronic tensile tester

Moreover, the integration of computer software allows for comprehensive data analysis and reporting. Users can visualize results through graphical representations, making it easier to interpret data and share findings with stakeholders. Advanced software solutions also enable the customization of testing parameters and conditions, such as the speed of loading and environmental settings, to simulate real-life scenarios more accurately.

The importance of safety cannot be overlooked when discussing tensile testing. The controlled environment of these electronic testers minimizes the risk of accidents that could occur during testing, as they often feature automatic shut-off mechanisms and safety enclosures. This safety aspect is particularly crucial when testing materials that may behave unpredictably under stress.

In addition to their capabilities in traditional tensile testing, modern electronic testers can also perform a variety of supplementary tests, such as compression and flexural testing. This multi-functionality makes them versatile tools in research and development labs where various mechanical properties need to be assessed on different materials.

Ultimately, the advancement of computer-controlled electronic tensile testers represents a significant step forward in material testing technology. These devices not only enhance the accuracy and reliability of test results but also streamline the testing process, allowing engineers and researchers to focus on analysis and innovation rather than manual procedures. As industries continue to evolve, the reliance on such sophisticated testing methods will undoubtedly grow, paving the way for the development of new materials that can withstand the demands of an ever-changing world.

In conclusion, computer-controlled electronic tensile testers are vital tools in the field of materials science, providing accurate and efficient means of evaluating the mechanical properties of various materials. Their integration of technology, safety features, and data analysis capabilities will play an essential role in the future of material testing and development.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

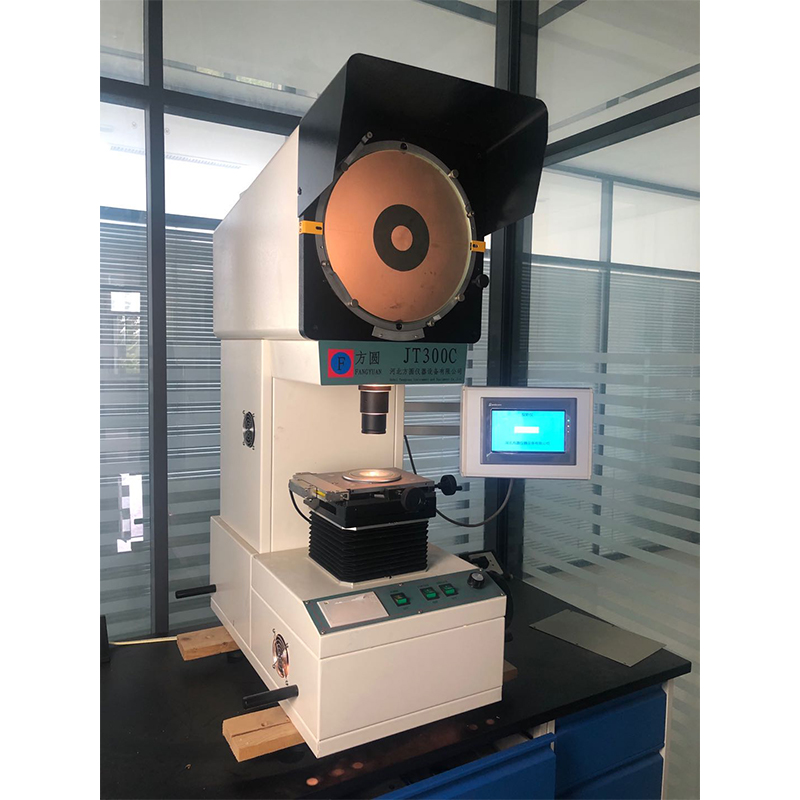

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy