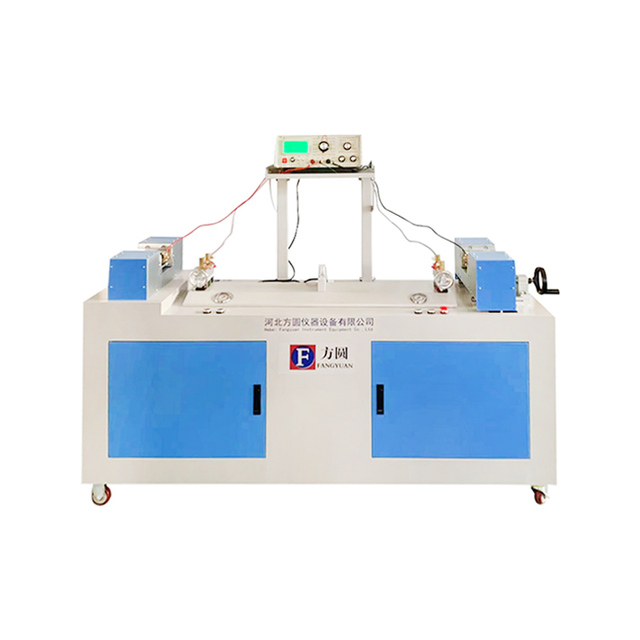

computer control tensile strength tester companies

The Role of Computer-Controlled Tensile Strength Testers in Material Testing

In the realm of materials science, understanding the properties of materials is imperative. One of the critical mechanical properties that determine the usability of materials, particularly metals and polymers, is tensile strength. This property measures how much force a material can withstand before failing under tension. To accurately evaluate tensile strength, various companies have developed advanced computer-controlled tensile strength testers, which offer precise, reliable, and reproducible results.

What are Tensile Strength Testers?

Tensile strength testers, often referred to as tensile testers or tensile machines, are specialized equipment designed to determine the tensile strength of materials. These machines apply a controlled pulling force to a specimen until it breaks. The data obtained allows professionals to analyze the material's behavior under stress, providing insights into its durability and potential applications.

The Evolution of Testing Technology

Traditionally, tensile testing was carried out using mechanical systems operated manually, leading to inconsistencies in results due to human error. However, with advancements in technology, the introduction of computer-controlled systems has revolutionized the field of material testing. These modern testers utilize sophisticated software to monitor the testing process, record data, and analyze results in real-time, ensuring higher accuracy and repeatability.

Key Advantages of Computer-Controlled Tensile Strength Testers

1. Precision and Consistency Computer-controlled tensile strength testers are designed to deliver precise measurements. The automation of the testing process reduces the chances of human error and variations, yielding consistent results across multiple tests. This is crucial in industries where material standards are stringent.

2. Data Management With integrated software solutions, these testers can store vast amounts of data efficiently. Users can generate detailed reports, graphs, and analytical insights from the testing data, facilitating comprehensive material analysis and enhancing decision-making processes.

3. Real-Time Monitoring Many advanced systems allow for real-time monitoring of the material's behavior under stress. This feature helps users to observe the material's performance as the test progresses, identifying key points such as yield strength and ultimate tensile strength immediately.

4. User-Friendly Interface Modern tensile strength testers often come equipped with intuitive interfaces, making them accessible even to personnel with limited technical knowledge. This ease of use encourages more widespread adoption across various sectors, from laboratories to production facilities.

computer control tensile strength tester companies

5. Versatility These testers are suitable for a wide range of materials, including metals, plastics, textiles, and composites. This versatility makes them invaluable tools in diverse industries, including aerospace, automotive, construction, and manufacturing.

Leading Companies in the Field

Several companies excel in producing computer-controlled tensile strength testers, each offering unique features and capabilities

1. Instron A leader in materials testing, Instron provides a range of tensile testers known for their reliability and cutting-edge technology. Their machines often feature sophisticated software for thorough data analysis.

2. MTS Systems Corporation MTS offers versatile testing solutions that can accommodate various specimen sizes and materials. Their systems are known for their robustness and high-performance capabilities.

3. ZwickRoell This company is renowned for innovative testing machines and solutions. They boast a comprehensive range of tensile strength testers suitable for industry and research applications.

4. Shimadzu Well-known for their precision instruments, Shimadzu produces tensile testing machines that emphasize accuracy and ease of use, making them popular among laboratories.

5. Tinius Olsen With a long history in materials testing, Tinius Olsen offers state-of-the-art tensile testers designed for durability and performance.

Conclusion

As industries continue to advance, the demand for high-quality materials with predictable performance is more critical than ever. Computer-controlled tensile strength testers have established themselves as essential tools for engineers, researchers, and manufacturers alike, ensuring that materials used in various applications meet required specifications. By investing in these advanced testing solutions, companies not only enhance their research capabilities but also contribute to the development of safer, more reliable products in the marketplace. As technology evolves, we can expect further improvements in testing equipment, leading to even more precise material evaluations and innovations in engineering and manufacturing processes.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy