Automated Universal Tensile Testing Machine Manufacturers for Enhanced Material Testing Solutions

The Emergence of Computer-Controlled Universal Tensile Testing Machines in Manufacturing

In the realm of manufacturing and material science, understanding the tensile properties of materials is crucial for ensuring the safety, reliability, and durability of products. The universal tensile testing machine (UTM) plays a pivotal role in this evaluation, facilitating the assessment of materials under various conditions. With advancements in technology, computer-controlled UTMs are becoming increasingly prevalent in factories worldwide, revolutionizing quality control and testing processes.

Computer-controlled universal tensile testing machines are sophisticated instruments designed to measure the tensile strength, elongation, yield strength, and other mechanical properties of materials. These machines are equipped with advanced sensors and software that enable precise control of testing parameters, providing accurate and repeatable results. The integration of computer technology has transformed traditional mechanical testing into a highly automated process, significantly improving efficiency and data accuracy.

One of the primary advantages of computer-controlled UTMs is their ability to execute complex testing protocols. They can be programmed to perform a variety of tests, including static, dynamic, and fatigue testing, making them versatile tools in the laboratory. This programmability allows for the standardization of testing procedures across different manufacturing facilities, ensuring consistency in results and facilitating compliance with international testing standards.

Moreover, the data collected from computer-controlled UTMs can be analyzed in real-time, providing immediate feedback to engineers and designers. This instant access to reliable data enables manufacturers to make informed decisions quickly. For example, if a specific batch of material does not meet the required specifications during testing, adjustments can be made promptly, reducing waste and ensuring that only materials that meet quality standards proceed to production.

computer control universal tensile testing machine factories

Additionally, modern UTMs often feature user-friendly interfaces and advanced software that simplify the testing process. Operators can easily input parameters and monitor test progress through graphical displays, making it accessible to personnel with varying levels of expertise. This ease of use encourages more widespread adoption of tensile testing in factories, promoting a culture of quality assurance throughout the manufacturing process.

The adoption of computer-controlled UTMs is also driven by the growing demand for high-performance materials in industries such as aerospace, automotive, and construction. As materials continue to evolve, understanding their mechanical properties becomes increasingly critical. Computer-controlled UTMs allow for the testing of new composites and alloys, facilitating the development of innovative materials that meet rigorous safety and performance standards.

In addition to enhancing testing capabilities, computer-controlled UTMs contribute to sustainability efforts within manufacturing. By minimizing testing errors and ensuring that only compliant materials are used, companies can reduce material waste. Furthermore, the automation of testing processes can lead to energy savings, as machines operate more efficiently compared to manual testing setups.

In conclusion, the rise of computer-controlled universal tensile testing machines in factories represents a significant advancement in material testing technology. Their ability to deliver accurate, reliable, and timely data enhances quality control, supports the development of innovative materials, and promotes sustainable practices in manufacturing. As industries continue to evolve, the importance of efficient and effective testing methods will only grow, making computer-controlled UTMs an indispensable asset in the quest for excellence in material performance. The future of testing technology looks bright, and the continued innovation in this field promises even greater efficiencies and capabilities moving forward.

-

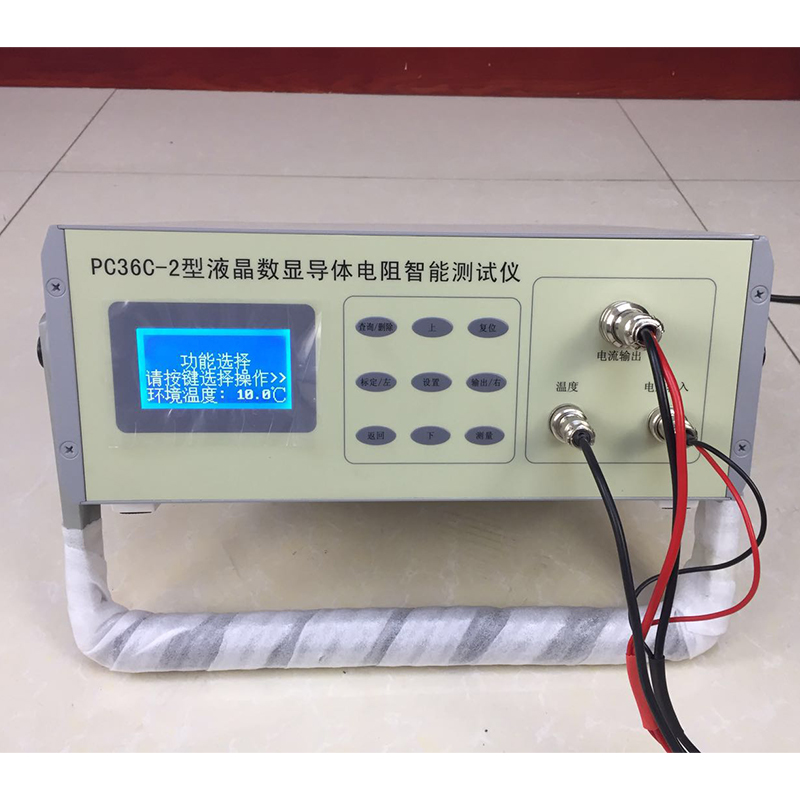

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy