Universal Tensile Testing Machine Manufacturer for Computer-Controlled Testing Solutions

The Evolution and Importance of Computer-Controlled Universal Tensile Testing Machines

In the realm of material science and engineering, the need for precise and reliable testing methods is paramount. This is where computer-controlled universal tensile testing machines (UCTMs) come into play. These advanced machines have revolutionized the way materials are tested, providing unparalleled accuracy and versatility in assessing their mechanical properties.

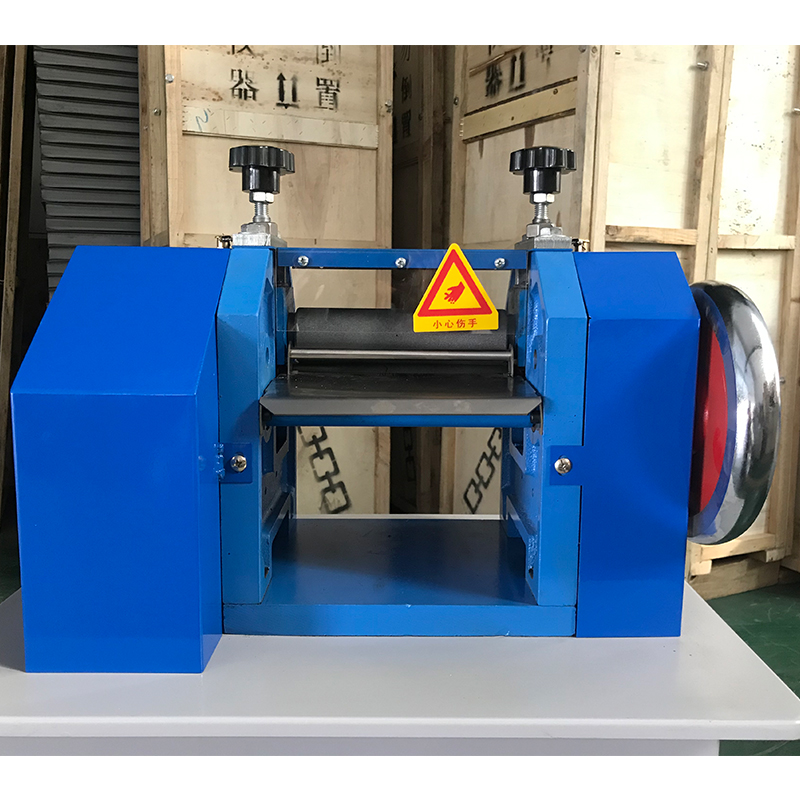

A universal tensile testing machine is designed to evaluate the tensile strength, compression, and flexural properties of materials. However, the integration of computer control has significantly enhanced these machines’ capabilities. Modern UCTMs are equipped with sophisticated software that allows for real-time data acquisition, analysis, and reporting. This technological advancement enables engineers and researchers to obtain precise measurements of a material's yield strength, tensile strength, elongation, and modulus of elasticity.

The core benefit of computer control in UCTMs is the automation of the testing process. Operators can set specific parameters for the test, such as loading rates, strain limits, and specimen dimensions, directly through the user-friendly interface. This automation ensures consistency and repeatability, which are critical for producing reliable data. Moreover, the software can generate graphical representations of the stress-strain curve, making it easier to interpret the material's behavior under load.

In factories and research laboratories, UCTMs play a crucial role in quality control and assurance. Manufacturers use these machines to verify that their products meet industry standards and specifications. By conducting regular tensile tests, companies can identify any defects or weaknesses in materials before they reach the market. This proactive approach not only enhances product quality but also safeguards against potential failures that could lead to costly recalls or safety hazards.

computer control universal tensile testing machine factory

The versatility of computer-controlled UCTMs is another key advantage. These machines can be adapted to test a wide variety of materials, including metals, plastics, composites, and textiles. This adaptability makes them essential not only in manufacturing but also in sectors such as aerospace, automotive, construction, and pharmaceuticals. Each industry requires specific testing protocols, and UCTMs can be configured to meet these varying demands.

Furthermore, the data generated by UCTMs can be integrated into research and development processes, providing insights that drive innovation. Engineers can use the results to develop new materials or improve existing ones, enhancing performance characteristics such as strength, flexibility, and overall durability.

As industries continue to evolve, the importance of accurate material testing cannot be overstated. With advancements in technology, computer-controlled universal tensile testing machines are becoming increasingly sophisticated, incorporating features like machine learning algorithms for predictive analysis and IoT capabilities for remote monitoring and diagnostics.

In summary, computer-controlled universal tensile testing machines are indispensable tools in the field of materials testing. Their precision, automation, and versatility enable manufacturers and researchers to gain valuable insights into material properties, ensuring safety, quality, and performance across various applications. As technology continues to advance, the role of UCTMs will only become more critical in shaping the future of material science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy