Conductor Resistance Test Instruments Supplier

Understanding Conductor Resistance Test Instruments Importance and Supplier Selection

In the realm of electrical engineering, conductor resistance testing plays a pivotal role in ensuring the reliability and safety of electrical systems. Conductor resistance tests are essential for evaluating the quality of electrical connectors, cables, and other conductive pathways. A reliable conductor resistance test instrument allows engineers and technicians to measure the resistance of conductors accurately, which is critical for maintaining optimal performance in electrical installations.

Conductor resistance testing is vital for several reasons. First, it helps in verifying that a conductor meets specific resistance standards set by industry regulations. High resistance can lead to overheating, energy losses, and even catastrophic failures in electrical circuits. Second, these tests aid in identifying issues such as corrosion, loose connections, and improper installations, which can compromise system integrity. Regular testing can prevent potential failures, making it not only a regulatory requirement but also a best practice in maintaining electrical systems.

When considering a supplier for conductor resistance test instruments, several factors come into play. First and foremost, the reliability of the instruments offered is crucial. A reputable supplier should provide products calibrated to deliver precise measurements, as inaccuracies can lead to suboptimal decisions in electrical system management. Look for suppliers whose instruments comply with industry standards to ensure consistency and safety.

Another important aspect is the range of products available. Different applications may require different types of instruments. Some projects might require portable handheld devices, while others might need benchtop equipment capable of measuring higher resistance levels. A supplier with a diverse product range can cater to various testing needs, ensuring you find the right tool for your specific application.

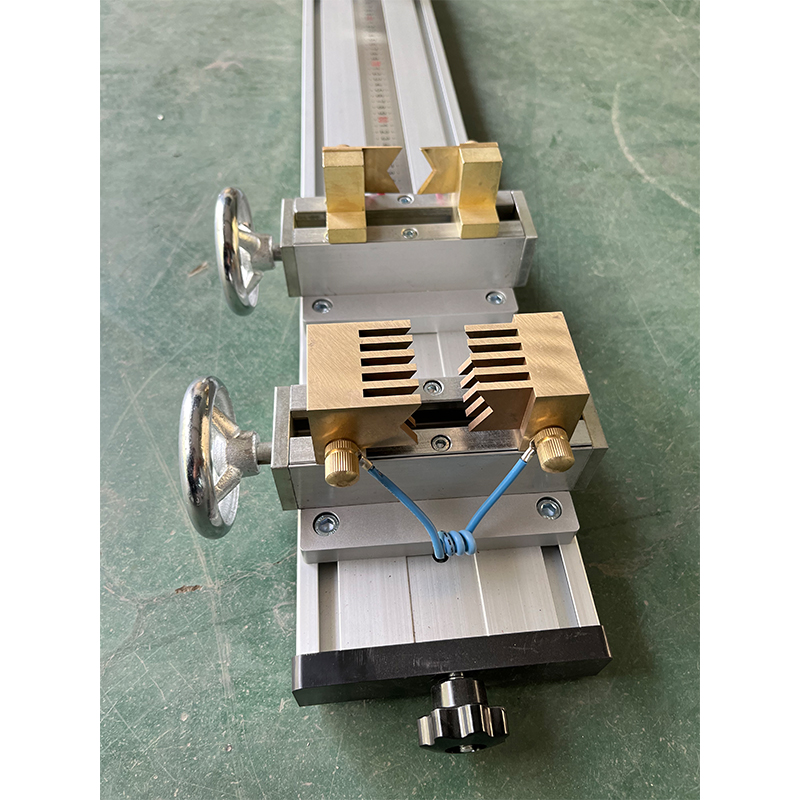

conductor resistance test instrument supplier

Support and service offered by the supplier is another key consideration. Technical support can be invaluable when interpreting test results or troubleshooting equipment issues. Suppliers that provide comprehensive after-sale services, including calibration, maintenance, and repair, enhance the overall user experience. Look for suppliers with a solid reputation for customer support, as this can save substantial time and resources in the long run.

Cost is, of course, a significant factor, but it should not be the only consideration. While budget constraints are understandable, investing in high-quality instruments from a reputable supplier can prevent more costly issues down the line. Cheaper instruments may save money upfront but can lead to inaccurate readings and potential failures, negating any initial savings.

Lastly, obtaining customer reviews and testimonials can provide valuable insights into a supplier’s reliability and product performance. Engaging with industry peers to gather recommendations can also guide you toward selecting a reputable supplier known for high-quality conductor resistance test instruments.

In conclusion, conductor resistance testing is an integral aspect of maintaining electrical system integrity, and selecting the right supplier for testing instruments is critical. By considering factors like instrument reliability, product range, support services, cost, and customer feedback, organizations can ensure they make informed decisions, ultimately leading to safer and more efficient electrical systems.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy