Constant Temperature Measurement System for Conductor Resistance Evaluation

The Importance of Conductor Resistance Constant Temperature Measurement Machines

In the field of electrical engineering, accurate measurement of conductor resistance is crucial for a variety of applications, ranging from power generation to telecommunications. Conductors, whether they are copper, aluminum, or other materials, exhibit resistance that varies with temperature. Therefore, a constant temperature measurement machine specifically designed for conductor resistance assessment plays a pivotal role in ensuring precise readings essential for effective system design, analysis, and performance.

The significance of measuring conductor resistance lies in its direct impact on efficiency and safety in electrical systems. Resistance leads to power loss in the form of heat, which can result in energy inefficiencies and potential hazards. For instance, in power transmission, even slight variations in conductor resistance due to temperature changes can lead to significant energy losses over long distances. By utilizing a constant temperature measurement machine, engineers can evaluate the resistance of conductors reliably, ensuring that the materials used meet specified standards and perform optimally under varying environmental conditions.

A constant temperature measurement machine operates under controlled thermal conditions to minimize the influence of ambient temperature fluctuations on resistance readings. This precision is crucial because the resistance of materials typically increases with rising temperatures due to the increased vibrational energy of atoms. Consequently, accurate resistance measurements must consider the specific temperature of the testing environment as well as the thermal characteristics of the conductor being tested.

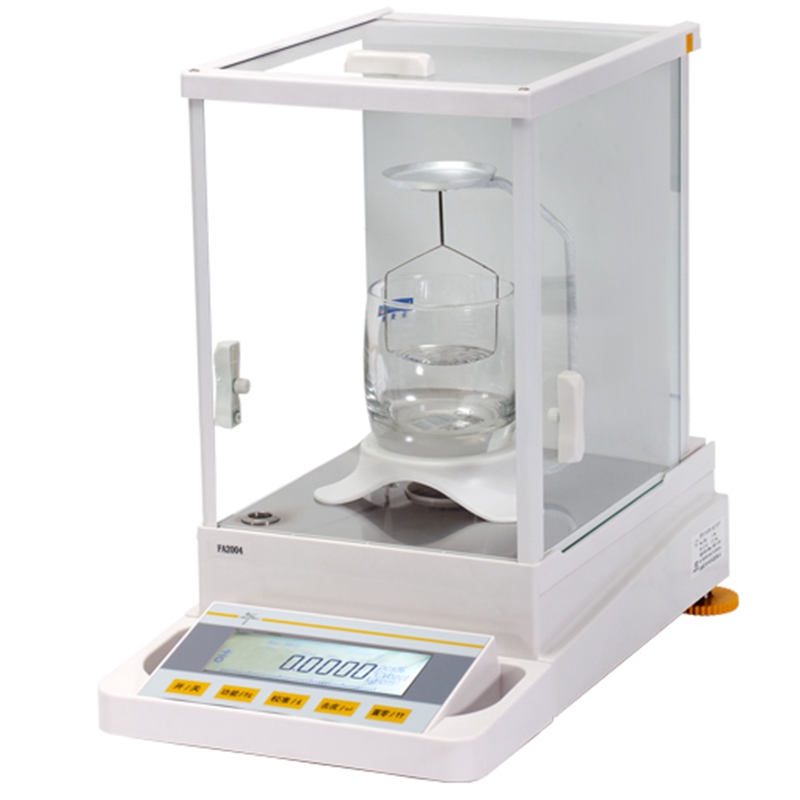

conductor resistance constant temperature measurement machine

Modern constant temperature measurement machines incorporate advanced technologies such as automated calibration systems, digital interfaces, and precise temperature control mechanisms. These features allow for quick and reliable resistance measurements while also offering the capability to log data over time for further analysis. Additionally, these machines are often designed to accommodate various conductor sizes and types, making them versatile tools for laboratories and field applications.

The testing process typically involves connecting the conductor to the measurement machine, where a controlled current is passed through it. The resulting voltage drop across the conductor is measured, allowing for the calculation of resistance according to Ohm's law. The machine ensures that the temperature of the conductor remains stable throughout this process, thereby providing accurate resistance values that can be compared against industry standards.

Industries such as aerospace, automotive, and renewable energy benefit greatly from the use of constant temperature measurement machines. In aerospace, for example, the reliability of electrical components is of utmost importance; thus, precise measurements aid in engineering designs that meet stringent safety regulations. Similarly, in renewable energy applications like solar panels, ensuring minimal resistance in electrical connections can lead to optimized performance and energy capture.

In conclusion, the role of conductor resistance constant temperature measurement machines is vital in enhancing the accuracy of resistance measurements. As industries continue to evolve and demand higher precision and reliability from electrical components, the adoption of these advanced measurement techniques will be essential in fostering innovation and ensuring safety in electrical systems worldwide. By providing engineers with reliable data, these machines not only enhance performance but also contribute to the sustainable development of electrical technologies.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy